Reinforcing steel bar and preparation method thereof

A steel bar and molten steel technology, applied in the field of alloy steel, can solve problems such as poor corrosion resistance and failure to reach the designed service life of reinforced concrete structures, achieve low cost, improve pitting corrosion resistance and intergranular corrosion resistance, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

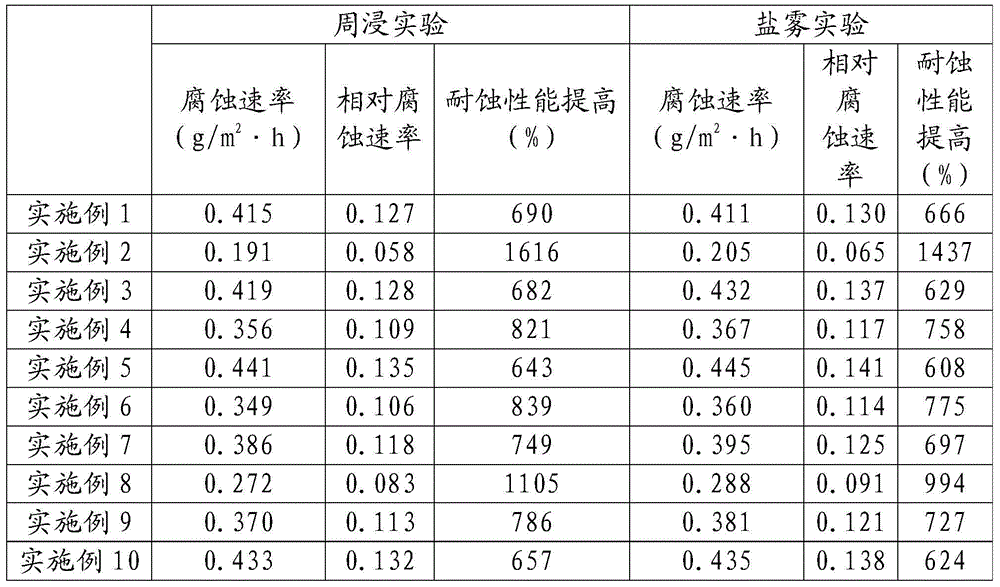

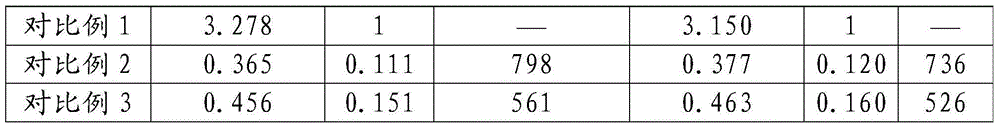

[0053] The present embodiment provides a steel bar, which is composed of the following elements: C, Si, Mn, P, S, Cr, Mo, Sn, RE, Fe and unavoidable impurities, wherein the weight percentage of each composition is as shown in Table 1, The mechanical properties are shown in Table 2, and the corrosion resistance is shown in Table 3.

[0054] Present embodiment also provides a kind of production method of reinforcing bar, comprises the steps:

[0055] S1: The step of pre-desulfurizing the molten iron by the KR method, and controlling the sulfur content to no more than 0.01%, because the sulfur element as an impurity element will reduce the mechanical properties and corrosion resistance of the steel, and the sulfur element cannot usually be removed in the converter Therefore, in order to reduce the sulfur content in the steel, it is necessary to pre-desulfurize the steel in molten iron. Before desulfurization, in order to improve the desulfurization efficiency, it is necessary to ...

Embodiment 2

[0062] The present embodiment provides a steel bar, which is composed of the following elements: C, Si, Mn, P, S, Cr, Mo, Sn, RE, Fe and unavoidable impurities, wherein the weight percentage of each composition is as shown in Table 1, The mechanical properties are shown in Table 2, and the corrosion resistance is shown in Table 3.

[0063] Present embodiment also provides a kind of production method of reinforcing bar, comprises the steps:

[0064] S1: The step of pre-desulfurizing the molten iron by the KR method, and controlling the sulfur content to no more than 0.01%, because the sulfur element as an impurity element will reduce the mechanical properties and corrosion resistance of the steel, and the sulfur element cannot usually be removed in the converter Therefore, in order to reduce the sulfur content in the steel, it is necessary to pre-desulfurize the steel in molten iron. Before desulfurization, in order to improve the desulfurization efficiency, it is necessary to re...

Embodiment 3

[0071] The present embodiment provides a steel bar, which is composed of the following elements: C, Si, Mn, P, S, Cr, Mo, Sn, RE, Fe and unavoidable impurities, wherein the weight percentage of each composition is as shown in Table 1, The mechanical properties are shown in Table 2, and the corrosion resistance is shown in Table 3.

[0072] Present embodiment also provides a kind of production method of reinforcing bar, comprises the steps:

[0073] S1: The step of pre-desulfurizing the molten iron by the KR method, and controlling the sulfur content to no more than 0.01%, because the sulfur element as an impurity element will reduce the mechanical properties and corrosion resistance of the steel, and the sulfur element cannot usually be removed in the converter Therefore, in order to reduce the sulfur content in the steel, it is necessary to pre-desulfurize the steel in molten iron. Before desulfurization, in order to improve the desulfurization efficiency, it is necessary to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com