Quantum-dot strengthened composite light conversion film and preparation method thereof

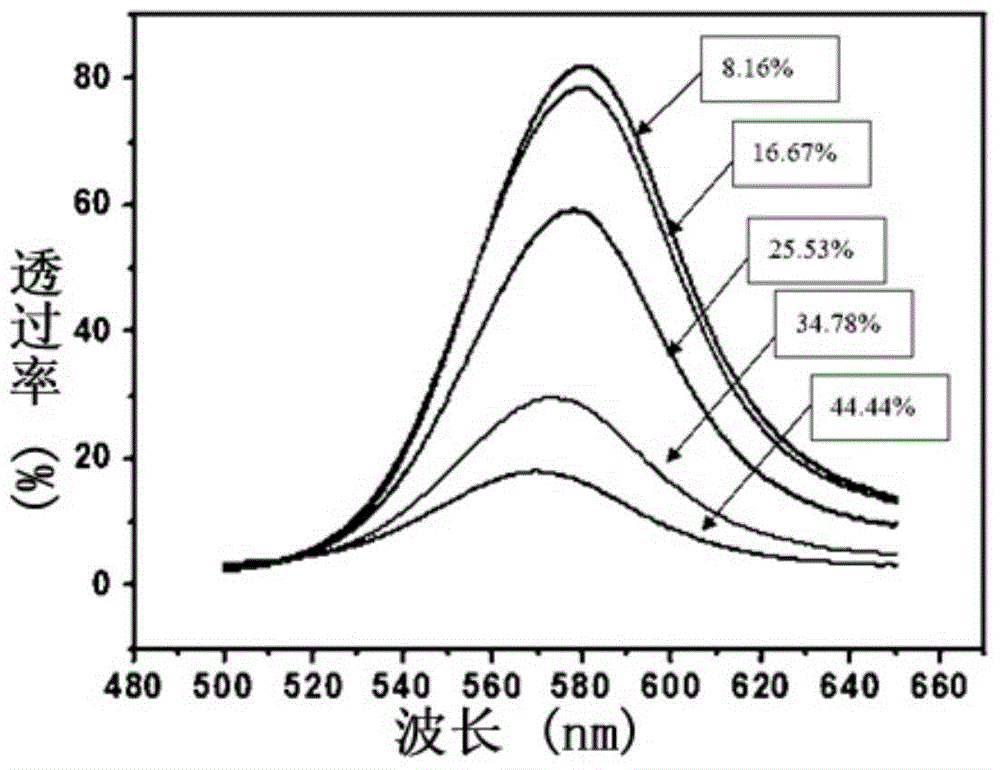

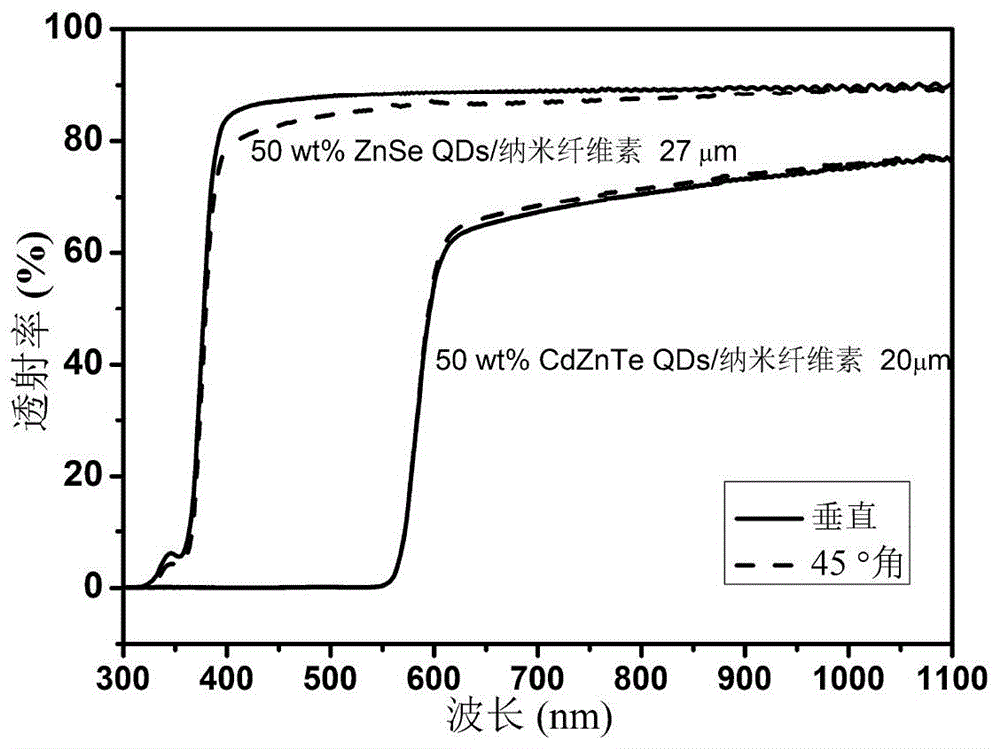

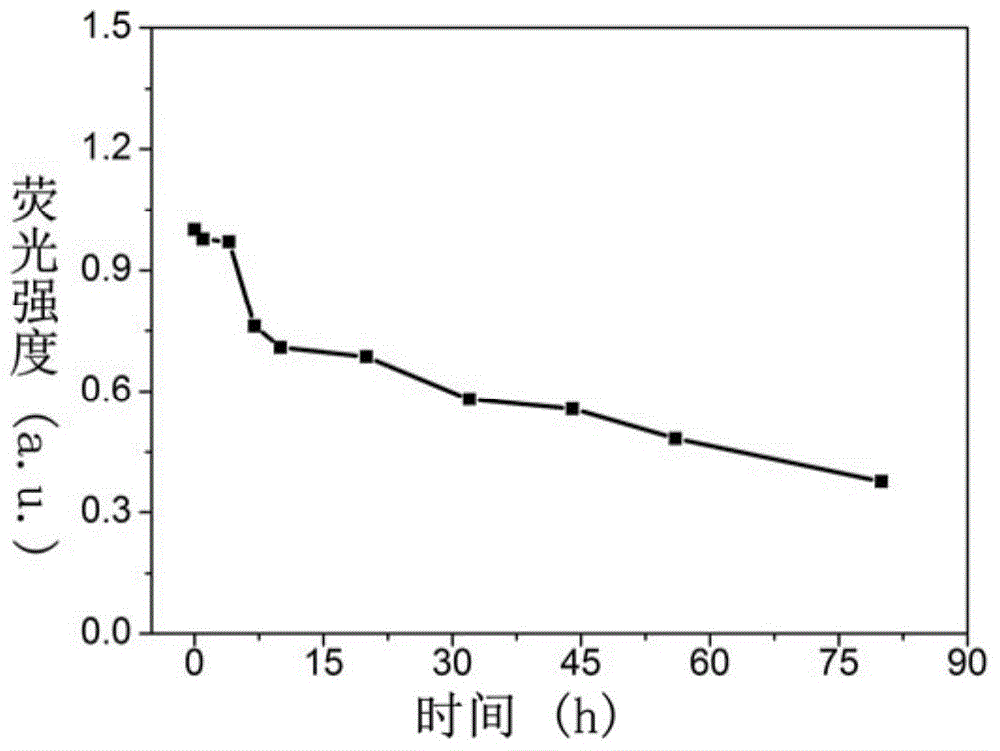

A technology of quantum dots and composite light, which is applied in the field of quantum dot enhanced composite light conversion film and its preparation, which can solve the problems of poor transparency of polymer matrix, low doping content of quantum dots, poor dispersion, etc., and achieve high transparency and stability , High doping content, high transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the quantum dot enhanced composite light conversion film proposed by the present invention comprises the following steps:

[0029](1) Add 0.016 g of 2,2,6,6-tetramethylpiperidine-nitrogen-oxide and 0.1 g of NaBr to 100 g of deionized water to obtain an aqueous solution, then add 1 g of cellulose to the aqueous solution to form a suspension , add 10 micromole NaClO solution (6% active chlorine, concentration is 1.6 mol / liter) in the suspension, stir vigorously at room temperature for 12 hours, will obtain suspension and pour 150 grams of deionized water, under 400 watts power Ultrasonic treatment for 4 minutes to obtain a homogeneous suspension, which was centrifuged at a speed of 8000 rpm and a centrifugation time of 20 minutes, the obtained supernatant was a nanocellulose dilute suspension, dilute suspension The mass fraction of nanocellulose in the liquid is 0.05-0.1wt%, the diameter of nanocellulose is nanoscale, the length of nanocellulose ...

Embodiment 1

[0035] Step 1: Add 0.016 gram of 2,2,6,6-tetramethylpiperidine-nitrogen-oxide and 0.1 gram of NaBr to 100 gram of deionized water, then add 1 gram of cellulose to the aqueous solution to form a uniform suspension, and add Add 10 micromoles of NaClO solution (6% active chlorine, 1.6 mol / liter) to the suspension, stir vigorously at room temperature for 12 hours, pour the obtained suspension into 150 grams of deionized water, and sonicate for 4 minutes at a power of 400 watts , to obtain a homogeneous suspension, the homogeneous suspension is centrifuged, the centrifugation speed is 8000 rpm, and the centrifugation time is 20 minutes, the obtained supernatant is a nanocellulose dilute suspension, and the nanofibers in the dilute suspension The mass fraction of element is 0.05wt%;

[0036] Step 2, rotating the dilute suspension of nanocellulose at 80° C. for 4 hours, and distilling off the solvent water to obtain a concentrated suspension of nanocellulose with a mass fraction of 0...

Embodiment 2

[0042] Step 1: Add 0.016 gram of 2,2,6,6-tetramethylpiperidine-nitrogen-oxide and 0.1 gram of NaBr to 100 gram of deionized water, then add 1 gram of cellulose to the aqueous solution to form a uniform suspension, and add Add 10 micromoles of NaClO solution (6% active chlorine, 1.6 mol / liter) to the suspension, stir vigorously at room temperature for 12 hours, pour the obtained suspension into 150 grams of deionized water, and sonicate for 4 minutes at a power of 400 watts , to obtain a homogeneous suspension, the homogeneous suspension is centrifuged, the centrifugation speed is 8000 rpm, and the centrifugation time is 20 minutes, the obtained supernatant is a nanocellulose dilute suspension, and the nanofibers in the dilute suspension The mass fraction of element is 0.05wt%;

[0043] Step 2, rotating the dilute suspension of nanocellulose at 80° C. for 4 hours, and distilling off the solvent water to obtain a concentrated suspension of nanocellulose with a mass fraction of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com