Selective laser fusion molding equipment for ceramic material

A technology of selective laser melting and ceramic materials, applied in the field of laser melting and forming equipment, can solve the problems of oxidation failure, inability to directly use the forming equipment, without considering the influence of high temperature preheating, etc., to prevent oxidation failure, the device structure is simple and feasible, and the improvement quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

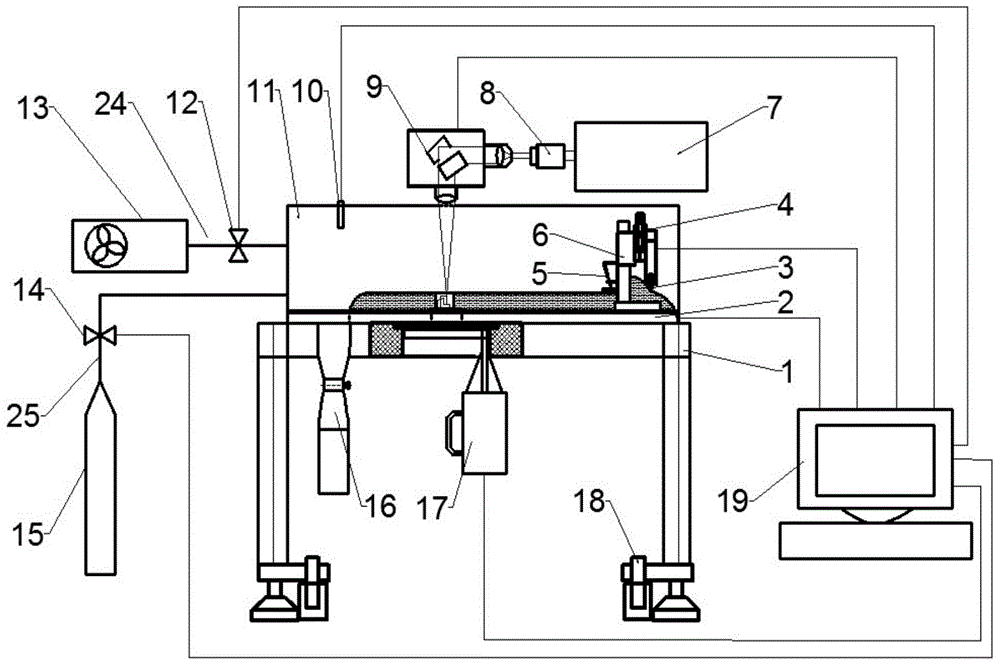

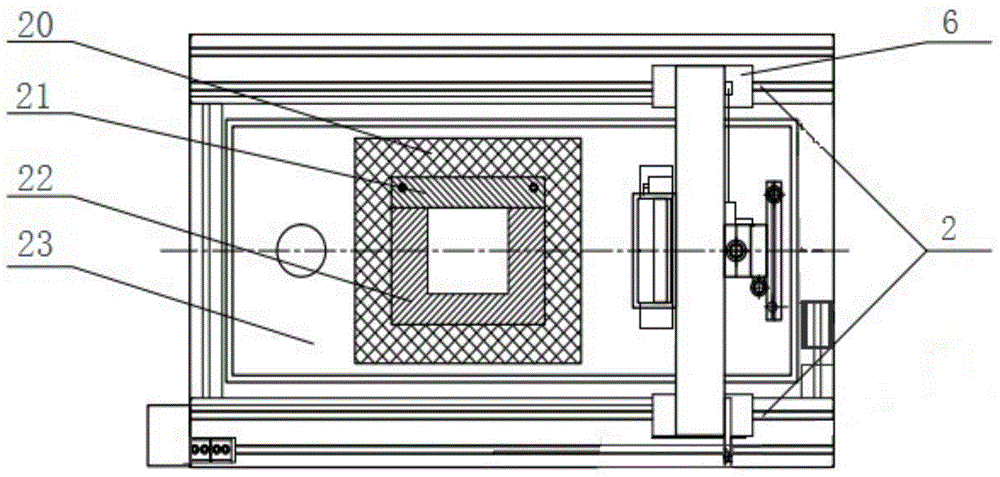

[0020] combine figure 1 and figure 2 , the present invention is used for selective laser melting forming equipment for ceramic materials, including a test bench 1, a linear rolling guide assembly unit 2, a scraper 3, an electric fine-tuning device 4, a feeding device 5, a bracket 6, a laser generator 7, and a dynamic focusing system 8, galvanometer system 9, pressure sensor 10, forming processing cabin 11, exhaust valve 12, vacuum pump 13, inflation valve 14, argon gas supply device 15, powder recoverer 16, induction heater 17, foot roller 18, Industrial computer 19, heat insulation board 20, pressure plate 21, transition board 22, work surface 23, air extraction device 24, inflation device 25. Wherein the test bench 1 is erected on the ground through the bottom foot roller 18, and the top surface of the test bench 1 is provided with a working surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com