Method for chemically strengthening lithium-aluminum-silicon glass

A lithium-aluminum-silicon and glass technology, applied in chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problems of easy breakage, poor drop resistance, difficult salt liquid exchange, etc., and achieve shortening and strengthening. time, increase the preheating temperature, and improve the performance of the glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

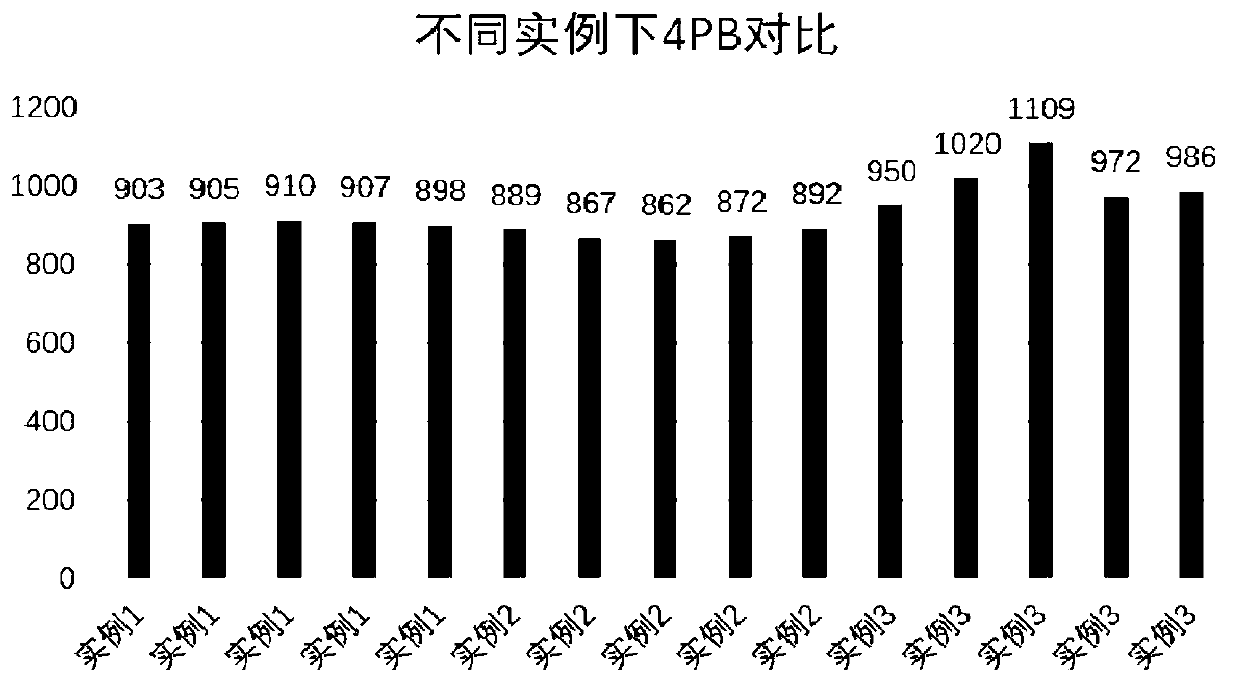

Embodiment 1

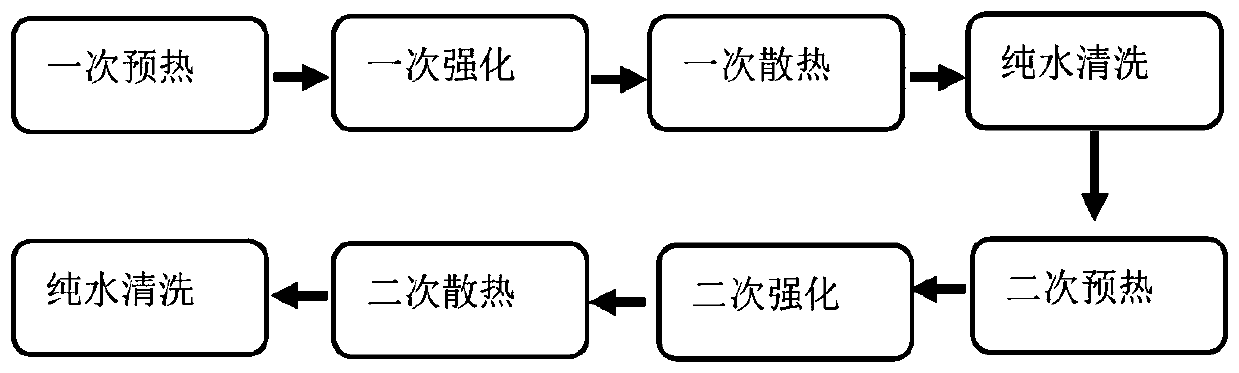

[0040] The chemical strengthening method of lithium aluminum silicate glass, concrete steps are:

[0041] 1. Select lithium-aluminum-silicon products and preheat them in a preheating furnace. The preheating temperature is 360°C and the time is 2 hours;

[0042] 2. The preheated product is strengthened once, and the ratio of sodium nitrate:potassium nitrate=65% is selected for the strengthening liquid. Strengthening time: 6h, strengthening temperature: 380°C.

[0043] 3. After the product is strengthened, move the product to the preheated furnace, open the furnace cover, turn off the heating switch, and cool down with the room temperature. When it is cooled to 100°C, perform pure water cleaning. The conditions for pure water cleaning are: rinse with pure water in two sinks in sequence. The temperature of pure water in the first sink is 55°C for 1 hour. The temperature of the pure water in the water is normal temperature, and the soaking time is: 1h. The pure water in the two...

Embodiment 2

[0050] The chemical strengthening method of lithium aluminum silicate glass, concrete steps are:

[0051] 1. Select lithium-aluminum-silicon products and preheat them in a preheating furnace. The preheating temperature is 370°C and the time is 3 hours;

[0052] 2. The preheated product is strengthened once, and the ratio of the strengthening liquid is: sodium nitrate: potassium nitrate = 75%. Strengthening time: 4h, strengthening temperature: 395°C.

[0053] 3. After the product is strengthened, move the product to the preheated furnace, open the furnace cover, and turn off the furnace heating switch, and cool down with the room temperature. When it is cooled to 100°C, perform pure water cleaning. The conditions for pure water cleaning are as follows: use pure water in two tanks for cleaning in sequence, the water tanks are flowing water, the water temperature in the first tank is 75°C, and the time is 30 minutes. , the temperature of the pure water in the second water tank ...

Embodiment 3

[0059] The chemical strengthening method of lithium aluminum silicate glass, concrete steps are:

[0060] 1. Select lithium-aluminum-silicon products and preheat them in a preheating furnace. The preheating temperature is 380°C and the time is 2.5 hours;

[0061] 2. The preheated product is strengthened once, and the proportion of the strengthening liquid is: sodium nitrate: potassium nitrate = 85%, and 0.5wt% of silicic acid is added to the strengthening liquid. Strengthening time: 5h, strengthening temperature: 390°C.

[0062] 3. After the product is strengthened, move the product to the preheated furnace, open the furnace cover, and turn off the furnace heating switch, and cool down with the room temperature. When cooled to 100°C, clean with pure water. The conditions for pure water cleaning are: clean with pure water from two tanks in sequence, the water tank is flowing water, the water temperature in the first tank is 65°C, and the time is 45 minutes. , the pure water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com