Reducing agent for regeneration of reaction material for processing nitrates in underground water and injection technology

A technology of reactive materials and reducing agents, applied in reduced water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of loss of reaction ability, reduction of nitrate removal ability of related composite materials, field engineering Difficult to realize and other problems, to achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

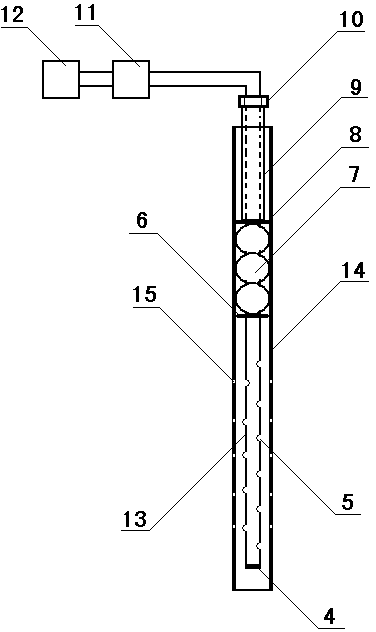

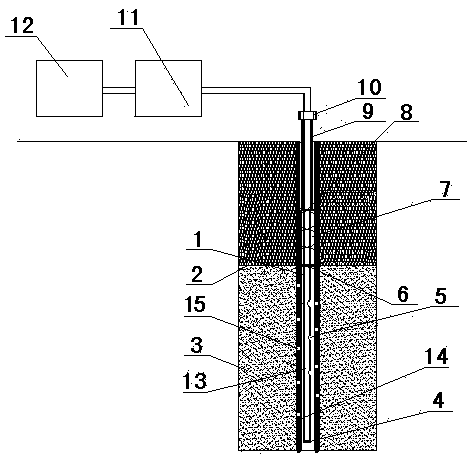

Method used

Image

Examples

Embodiment Construction

[0014] A regenerated reducing agent for treating groundwater nitrate reaction materials, characterized in that: the reducing agent molecular formula is C 6 h 8 o 6 , in the form of solid powder, soluble in water, is a widely used food additive, the price is relatively low, soluble in water, forming a true solution with a certain concentration, according to the preliminary test, in the high-valent iron (F e 3+ ), adding this reducing agent can make F e 3+ Revert to F e 2+ , to restore the ability to process nitrate, the basic reaction process is as follows:

[0015] Fe(OH) 3↓ +3H + → F e 3+ +3H 2 o

[0016] 2F e 3+ + C 6 h 8 o 6 →C 6 h 6 o 6 + 2F e 2+ +2H +

[0017] The reducing agent used has strict requirements. It cannot be poisonous or harmful. It cannot generate harmful and toxic substances when it reacts with various ions in groundwater, and the price should be reasonable. After extensive selection and experiments, this reducing agent that mee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com