Preparation method of potassium sulfate

A technology of potassium sulfate and soft potassium, which is applied in the field of preparing potassium sulfate by flotation process, can solve the problems of limited solvency, waste of Glauber’s salt ore, and large amount of circulating materials, so as to reduce the amount of material circulation, avoid the loss of potassium salt, and shorten the process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

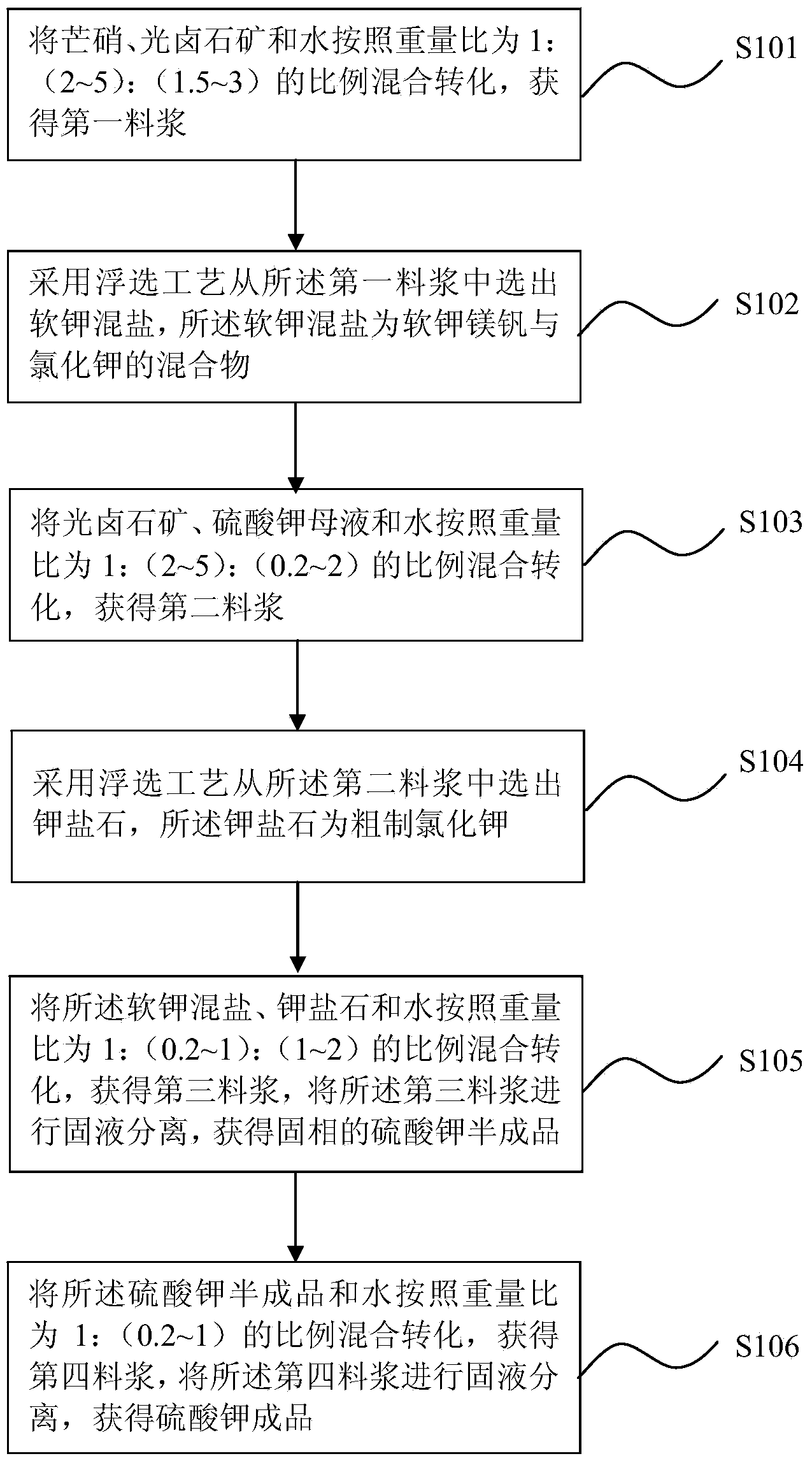

[0039] refer to figure 1 , the preparation method of the potassium sulfate provided in this specific embodiment comprises steps:

[0040] S101. Mix and transform Glauber's salt, carnallite ore and water according to a weight ratio of 1:(2-5):(1.5-3) to obtain a first slurry;

[0041] S102. Using a flotation process to select soft potassium mixed salt from the first slurry, the soft potassium mixed salt is a mixture of soft potassium magnesium vanadium and potassium chloride;

[0042] S103. Carnallite ore, potassium sulfate mother liquor and water are mixed and converted according to a weight ratio of 1: (2-5): (0.2-2), to obtain a second slurry;

[0043] S104, using a flotation process to select potash rock from the second slurry, and the potash rock is crude potassium chloride;

[0044] S105. Mix and transform the soft potash mixed salt, sylvitite and water according to a weight ratio of 1:(0.2-1):(1-2) to obtain a third slurry, and carry out the third slurry Solid-liquid ...

Embodiment 1

[0050] 1. Mix and transform Glauber's salt, carnallite ore and water at a weight ratio of 1:2:1.5 to obtain slurry I. Among them, in this step, the temperature of mixed transformation is 15°C, and the time of mixed transformation is 2.5h; the carnallite ore is chloride type Yantian carnallite ore, and its main components are: NaCl+KCl MgCl 2 ·6H 2 O.

[0051] 2. The soft potassium mixed salt is selected from the slurry I by flotation process, and the soft potassium mixed salt is a mixture of soft potassium magnesium vanadium and potassium chloride. Specifically, firstly, the slurry I is injected into the pulping tank, and the pulping mother liquor and the flotation agent are added for slurrying, so that the pulp concentration (the weight content of solids in the pulp) is 15%, and the contact time between the flotation agent and the pulp is 15%. It can reach more than 3 minutes; then the adjusted pulp goes through the flotation process of one coarse, one sweep and two fines i...

Embodiment 2

[0057] 1. Mix and transform Glauber's salt, carnallite ore and water in a weight ratio of 1:5:3 to obtain slurry I. Wherein, in this step, the temperature of mixed transformation is 35°C, and the time of mixed transformation is 0.5h; the carnallite ore adopts chloride type Yantian carnallite ore, and its main components are: NaCl+KCl·MgCl 2 ·6H 2 O.

[0058] 2. The soft potassium mixed salt is selected from the slurry I by flotation process, and the soft potassium mixed salt is a mixture of soft potassium magnesium vanadium and potassium chloride. Specifically, firstly inject the slurry I into the slurry tank, add the slurry mother liquor and the flotation agent to adjust the slurry, make the pulp concentration (the weight content of the solid in the slurry) be 40%, and make the contact time of the flotation agent and the slurry It reaches about 15 minutes; then the adjusted pulp goes through the flotation process of one coarse, one sweep and two fines in turn to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com