A kind of power lower type tie rod press

A technology of presses and tie rods, which is applied in presses, stamping machines, manufacturing tools, etc., can solve the problems of poor mechanical properties of presses, ineffective hydraulic cylinder acceleration, large vibration and noise, etc., to meet the requirements of strength and rigidity Requirements, superior comprehensive performance, and the effect of improved stress conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

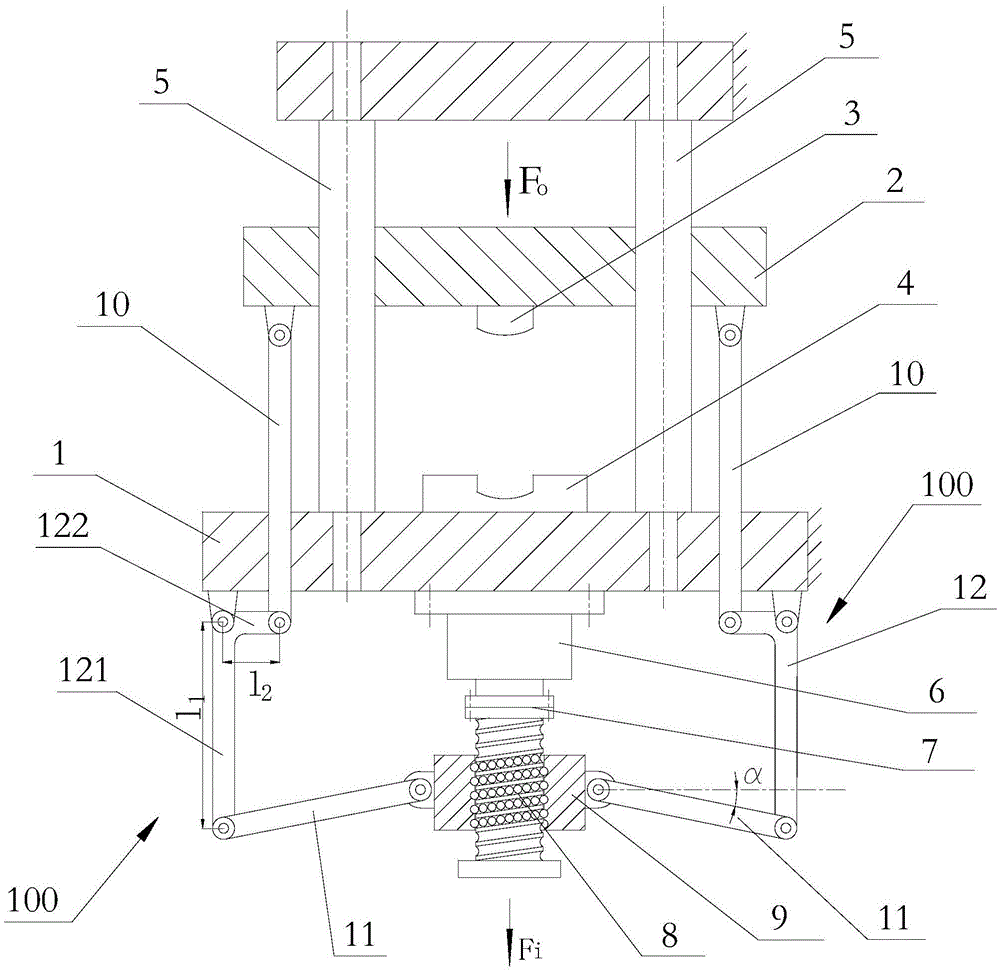

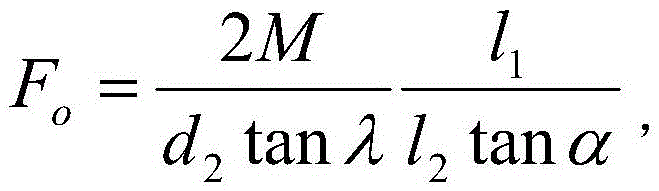

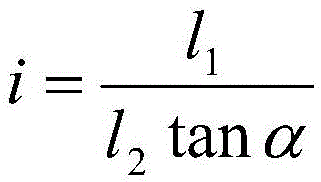

[0019] see figure 1 The shown press includes a workbench 1 fixedly arranged on the frame, an upper mold assembly 2 that is vertically lifted and lowered on the frame and positioned above the workbench 1, and the upper mold assembly 2 includes an upper and lower The sliding seat 2 that is lifted and lowered on the frame, the upper mold 3 that is fixedly arranged under the sliding seat 2, the lower mold 4 that matches the upper mold 3 is fixedly arranged on the workbench 1, and the upper mold 4 is installed on the workbench 1. There are a plurality of vertically extending guide posts 5 to provide guidance for the sliding seat 2 to slide up and down.

[0020] The press also includes a motor 6 fixedly installed under the workbench 1 , a lead screw 8 connected to the output shaft of the motor 6 , and a nut 9 sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com