Bidirectional grinding-peeling type ore crusher

A crushing machine, grinding and stripping technology, applied in the field of mining machinery, can solve problems such as machine wear and tear, and achieve the effect of saving floor space and high productivity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

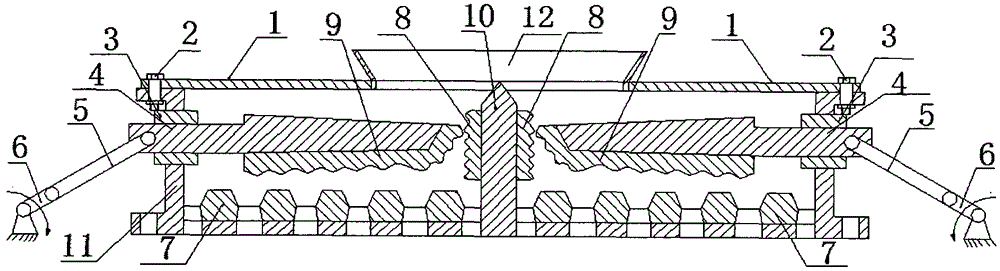

[0012] figure 1 Shown is a two-way grinding and stripping type ore crusher, including a cuboid box body 11 and a cover plate 1 fixed on the upper part of the box body 11 by bolts 2, and the middle part of the cover plate 1 is provided with a feed port 12; A partition 10 is arranged below, lining boards 8 are arranged symmetrically on both sides of the partition 10, and a lower grinding plate 7 is arranged on the bottom of the box body 11; Inside is provided with the slide block 4 that can move back and forth. The front end of the slider 4 is provided with an upper grinding plate 9 corresponding to the lower grinding plate 7, and its rear end is connected with the crank 6 through the connecting rod 5 to form a slider crank mechanism. Crank 6 is connected with external driving device. The external driving device adopts an electric motor. Wherein, the lower grinding plate 7 is provided with a trapezoidal groove. The bottom surface of the upper grinding plate 9 is a sawtooth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com