Chitosan-polypeptide complex for health product preparation and preparation method thereof

A polypeptide complex and chitosan technology, applied in the fields of application, food ingredients, food science, etc., can solve problems such as poor solubility, poor absorption, and difficulty in exerting efficacy, and achieve anti-side effects, promote blood vessel formation, and reduce free radicals the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

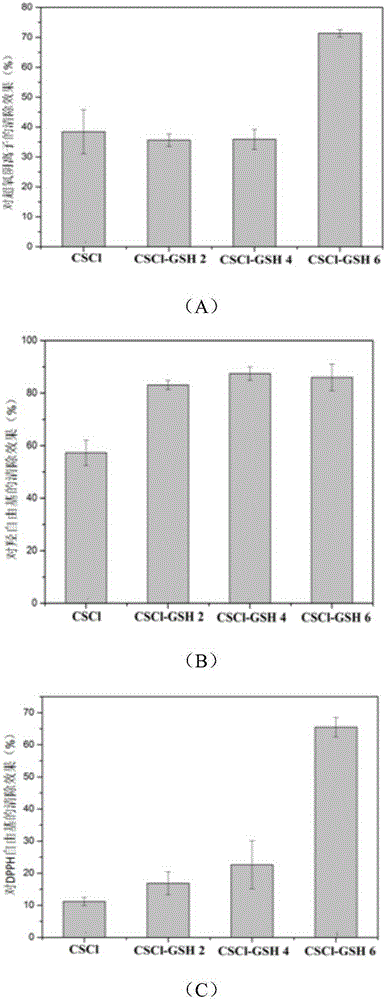

[0033] Example 1 Preparation of chlorinated chitosan-glutathione complex with a degree of substitution of 10%

[0034] (1) Weigh 0.5g of chlorinated chitosan, dissolve in 100ml of deionized water, and set aside.

[0035] (2) Dissolve 0.78g MAL-PEG-NHS in 10ml PBS (pH=8.0), add it dropwise to the solution prepared in step (1), and stir at room temperature for 2h.

[0036] (3) The product obtained in step (2) was ultrafiltered (Ultra-15, molecular weight cut-off 10KDa) with an ultrafiltration tube, and the product was dissolved in 100 ml of PBS (pH=7.0).

[0037] (4) Dissolve 0.093 g of glutathione in 10 ml of deionized water, and add it dropwise to the solution obtained in step (3).

[0038] (5) After stirring at room temperature for 24 hours, the mixed liquid was put into a dialysis bag for dialysis for 48 hours. Freeze-drying to obtain chlorinated chitosan-glutathione complex (CSCl-GSH2).

Embodiment 2

[0039] Example 2 Preparation of Chlorinated Chitosan-Glutathione Complex with a Degree of Substitution of 20%

[0040] (1) Weigh 0.5g of chlorinated chitosan, dissolve in 100ml of deionized water, and set aside.

[0041] (2) Dissolve 0.156g MAL-PEG-NHS in 10ml PBS (pH=8.0), add it dropwise to the solution prepared in step (1), and stir at room temperature for 2h.

[0042] (3) The product obtained in step (2) was ultrafiltered (Ultra-15, molecular weight cut-off 10KDa) with an ultrafiltration tube, and the product was dissolved in 100 ml of PBS (pH=7.0).

[0043] (4) Dissolve 0.186 g of glutathione in 10 ml of deionized water, and add it dropwise to the solution obtained in step (3).

[0044] (5) After stirring at room temperature for 24 hours, the mixed liquid was put into a dialysis bag for dialysis for 48 hours. Freeze-drying to obtain chlorinated chitosan-glutathione complex (CSCl-GSH4).

Embodiment 3

[0045] Example 3 Preparation of chlorinated chitosan-glutathione complex with a degree of substitution of 30%

[0046] (1) Weigh 0.5g of chlorinated chitosan, dissolve in 100ml of deionized water, and set aside.

[0047] (2) Dissolve 2.36g MAL-PEG-NHS in 10ml PBS (pH=8.0), add it dropwise to the solution prepared in step (1), and stir at room temperature for 2h.

[0048](3) The product obtained in step (2) was ultrafiltered with an ultrafiltration tube (Ultra-15, molecular weight cut-off 10KDa), and the product was dissolved in 100ml of PBS (pH=7.0).

[0049] (4) Weigh 0.278g of glutathione and dissolve it in 10ml of deionized water, and add it dropwise to the solution obtained in step (3).

[0050] (5) After stirring at room temperature for 24 hours, put the mixed liquid into a dialysis bag and dialyze for 48 hours. Chlorinated chitosan-glutathione complex (CSCl-GSH6) was obtained by freeze-drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com