Manufacturing method of lithium ion mixed type capacitor and lithium ion mixed type capacitor

A technology of hybrid capacitors and lithium ions, which is applied in the manufacture of hybrid capacitors, hybrid/electric double layer capacitors, capacitors, etc., can solve the problems of reducing device energy density, increasing process costs, and no longer having limited electrochemical capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the positive electrode and the negative electrode is: after the active material, the binder and the conductive agent are uniformly mixed into a slurry in a certain proportion, the coating machine is used to coat the current collector without through holes, and after drying, it is rolled, Cutting to obtain the pole piece of the electrode.

[0020] The binders are polyvinylidene fluoride (PVDF), polytetrafluoroethylene (PTFE), sodium carboxymethyl cellulose (CMC), styrene-butadiene rubber (SBR) and LA series water-based adhesive produced by Chengdu Yindile. binder, etc. The conductive agent is selected from conductive carbon black, conductive graphite or carbon nanotubes. The current collector of the positive electrode is aluminum foil without through holes, and the current collector of the negative electrode is copper foil without through holes. The positive electrode active material is composed of one kind of lithium ion battery positive elec...

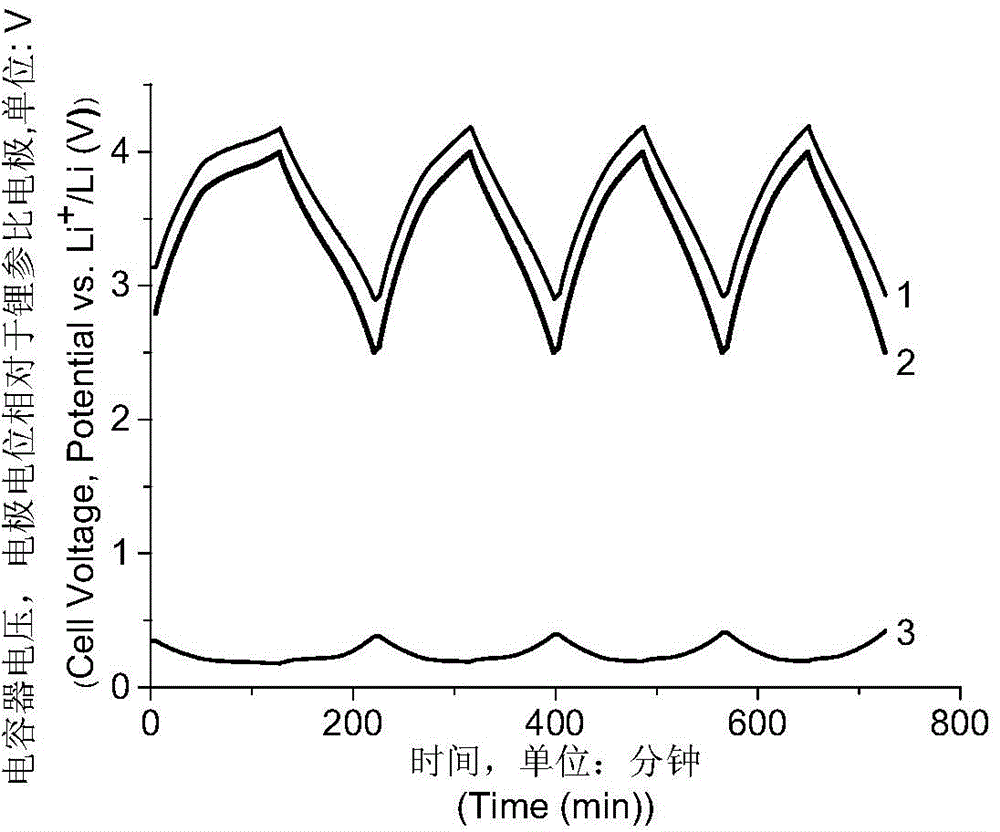

Embodiment 1

[0030]The active material of the negative electrode is artificial graphite CAG-3MT, the binder is sodium carboxymethyl cellulose and styrene-butadiene rubber, and the conductive agent is conductive carbon black Super C45. According to artificial graphite: conductive carbon black: sodium carboxymethyl cellulose: The mass ratio of styrene-butadiene rubber = 90:5:2:3 is mixed evenly to make a slurry, which is coated on a 12-micron thick copper foil without through holes. After drying, it is rolled and cut to obtain the negative pole piece. The areal density of one side of the pole piece coating layer is 39.3g / m 2 .

[0031] The active material of the positive electrode is lithium nickel cobalt manganese oxide LiNi 0.5 co 0.2 mn 0.3 o 2 , the high specific surface area carbon material is activated carbon YP50F, the binder is polyvinylidene fluoride, the conductive agent is conductive carbon black Super C45 and conductive graphite KS-6, according to activated carbon: nickel cob...

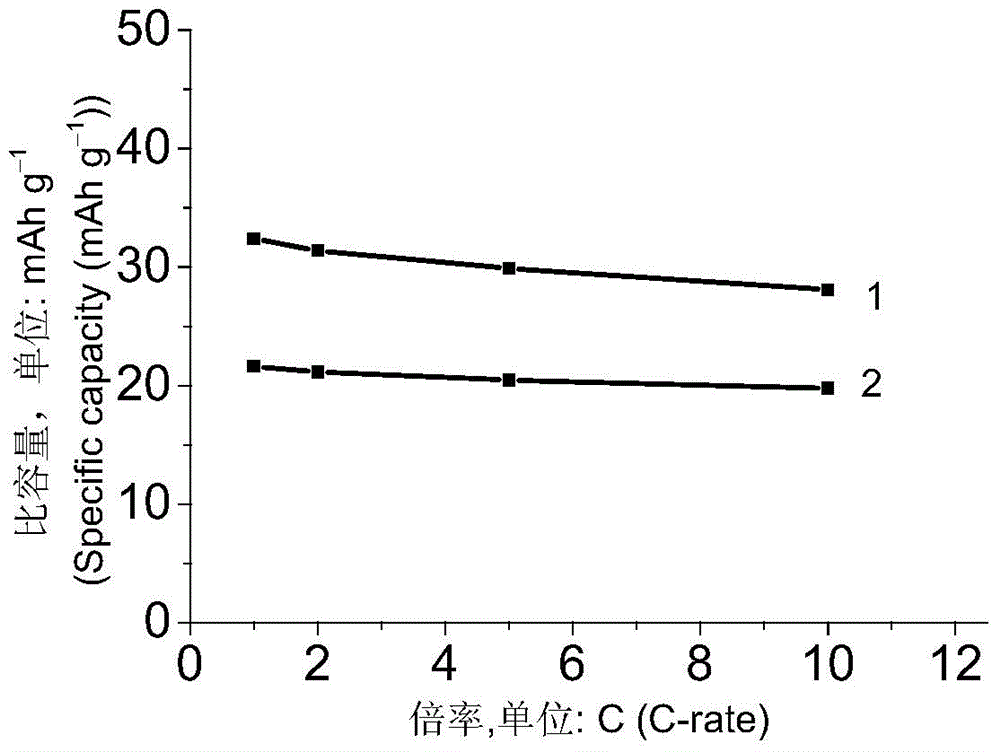

Embodiment 2~6

[0038] The active material of the negative electrode of embodiment 2~6 is hard carbon LN-0010, and binding agent is sodium carboxymethyl cellulose and styrene-butadiene rubber, and conductive agent is conductive carbon black Super C45, press hard carbon: conductive carbon black: carboxyl Sodium methylcellulose: styrene-butadiene rubber = 90:5:2:3 mass ratio mixed evenly to make a slurry, coated on a 12 micron thick copper foil without through holes, rolled and cut after drying Obtain the pole piece of the negative electrode. The areal density of one side of the pole piece coating layer is 47.0g / m 2 .

[0039] The active material of the positive electrode is lithium nickel cobalt manganese oxide LiNi 0.5 co 0.2 mn 0.3 o 2 , the high specific surface area carbon material is activated carbon YP50F, the binder is polyvinylidene fluoride, the conductive agent is conductive carbon black Super C45 and conductive graphite KS-6, according to the positive electrode active material:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com