LED backlight driving circuit and liquid crystal display

A backlight drive circuit and LED light string technology, which is applied in static indicators, optics, instruments, etc., can solve the problems of drive circuit drive efficiency deterioration, achieve the goals of reducing drive frequency, lower power consumption, and improving drive efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with embodiments in conjunction with the accompanying drawings.

[0032] Such as figure 2As shown, this embodiment provides a liquid crystal panel 200 and a backlight module 100 that are arranged oppositely, and the backlight module 100 provides a display light source to the liquid crystal panel 200, so that the liquid crystal panel 200 displays images, wherein, The backlight module 100 adopts LED backlight.

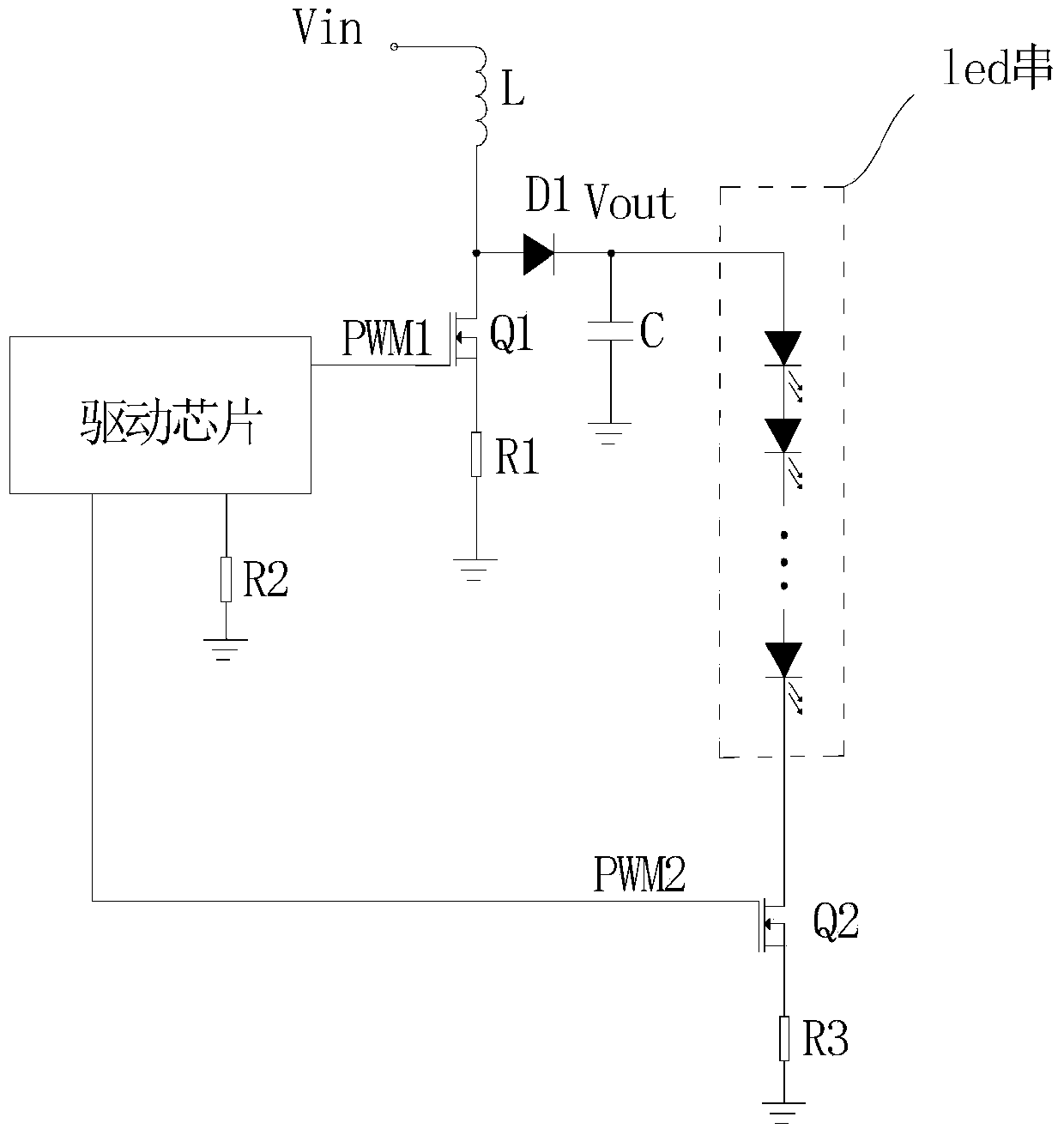

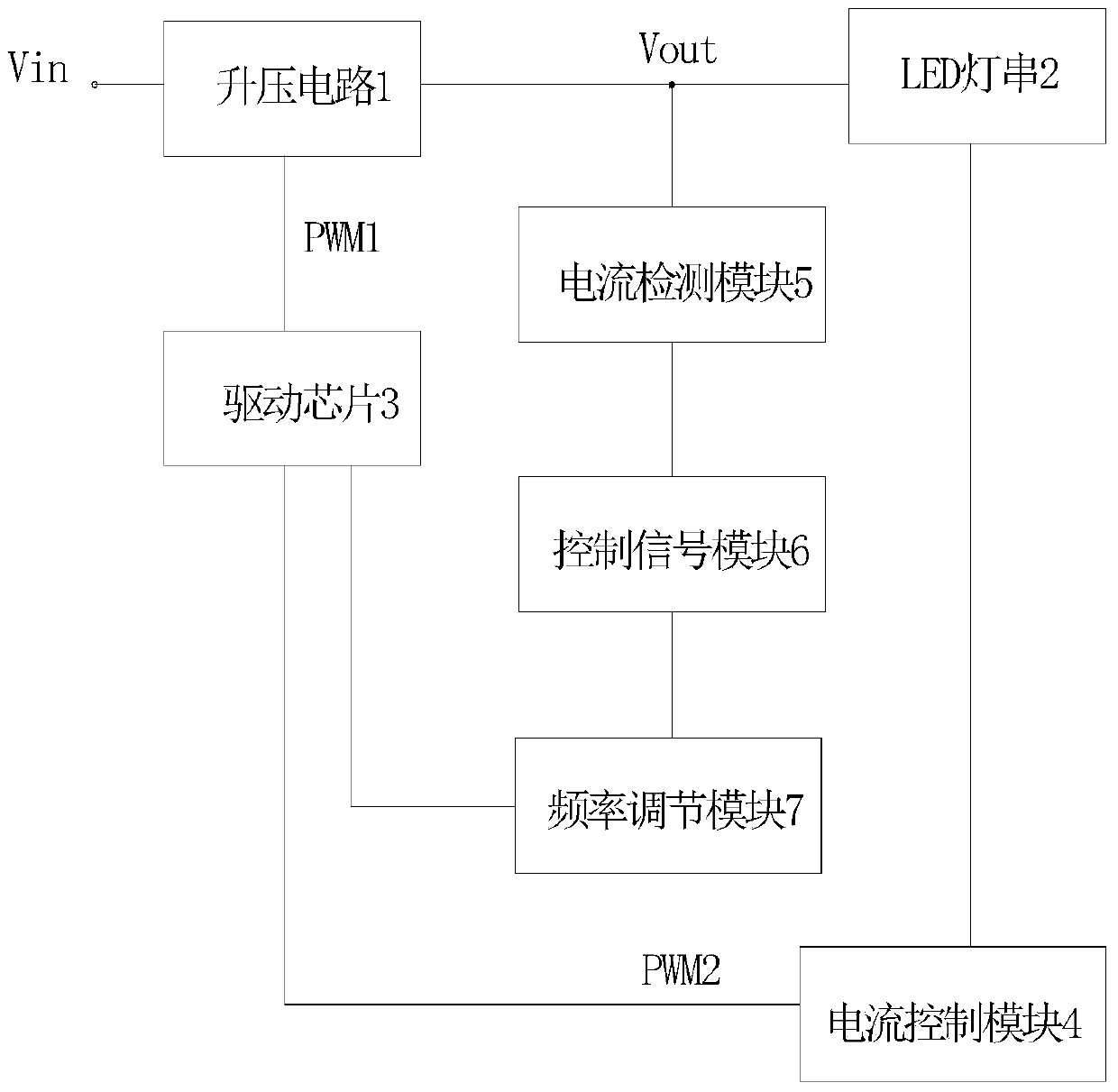

[0033] refer to Figure 3-7 , the driving circuit of the LED backlight is provided in this embodiment. image 3 Is the connection block diagram of the drive circuit. Such as image 3 As shown, the drive circuit includes: a booster circuit 1, which is used to convert the input voltage Vin into a required output voltage Vout and provide it to the LED light string 2; a current control module 4, connected to the negative terminal of the LED light string 2 , used to adjust the working current of the LED light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com