Method and device for separating heavy aromatics from catalytic cracking oil slurry

A technology for catalytically cracking oil slurry and heavy aromatics, which is applied in the field of separating aromatics to achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

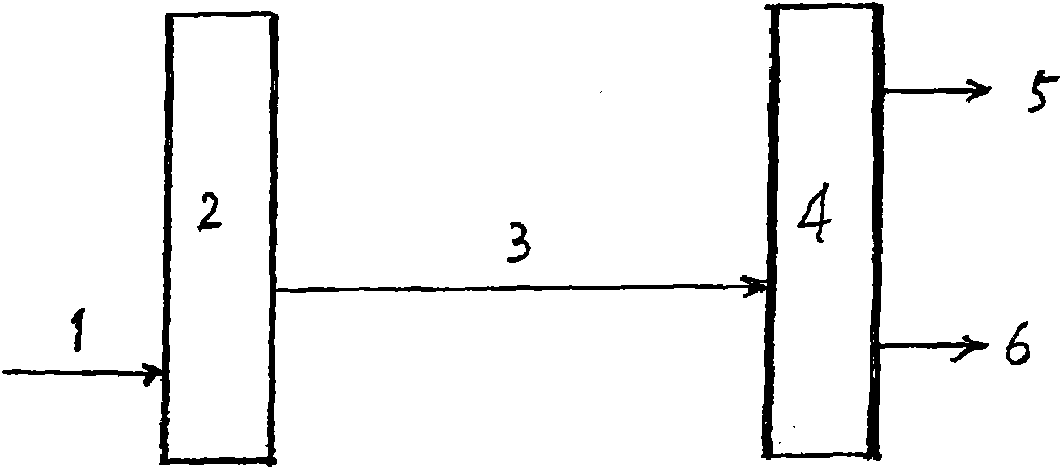

[0047] use as figure 1 The experimental device shown in Table 4 is used to separate heavy aromatics from catalytic cracking oil slurry according to the amount of raw material for catalytic cracking oil slurry. Among them, the catalytic cracking oil slurry is heated to about 375 °C, enters a vacuum tower with 14 theoretical plates, and is decompressed under a vacuum of 2 kPa to separate the extracted oil at 350-500 °C; the extracted oil Enter the extraction device (theoretical plate number is 6) to carry out heavy aromatics extraction with furfural. Among them, the feed ratio of furfural to extraction oil is 1.5:1 (weight ratio), and the extraction temperature is 85° C. to obtain raffinate and heavy aromatics.

[0048] The properties of the decompression extraction oil are shown in Table 2 below:

[0049] Table 2 Raw material decompression extraction oil properties

[0050]

[0051] The properties of the produced wax oil and aromatics are shown in Table 3 below.

[0052]...

Embodiment 2

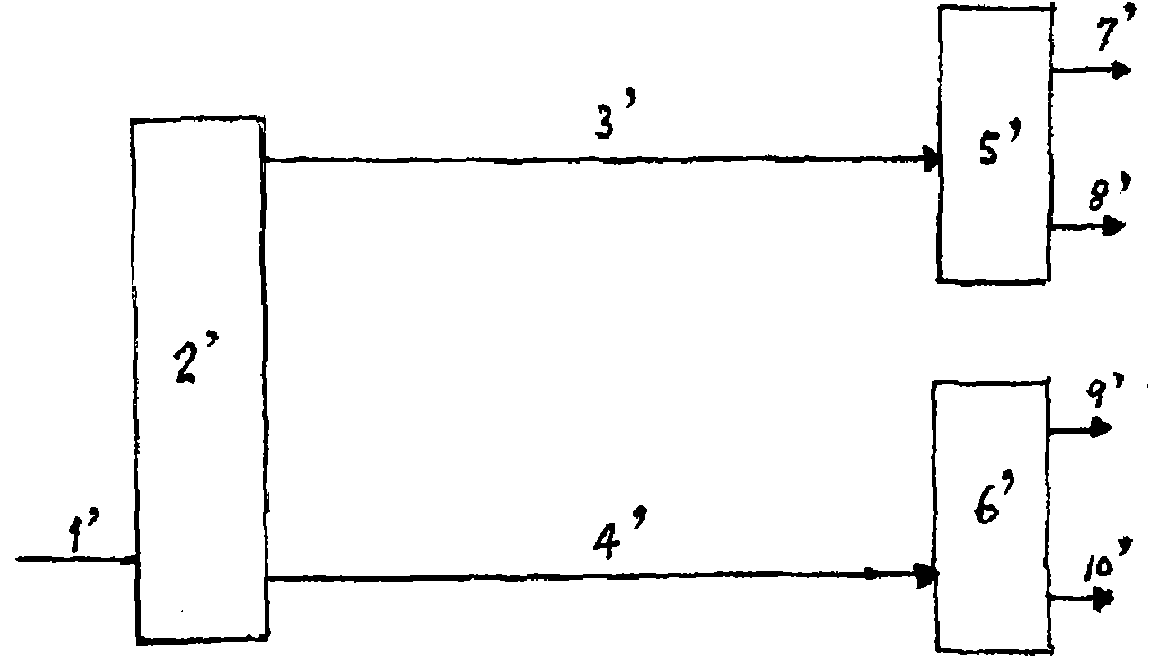

[0058] use as figure 2 The experimental device shown in Table 7 is used to separate heavy aromatics from catalytic cracking oil slurry according to the raw material amount of catalytic cracking oil slurry shown in Table 7. Among them, the catalytic cracking oil slurry is heated to 380°C, enters a packed tower (vacuum tower) with 14 theoretical trays, and is decompressed and pulled out under a vacuum of 2kPa to separate the minus line pulled out at 350-450°C. Oil and 450-500°C minus second-line pull-out oil. The two extracted oils were sent to different extraction devices (both with 6 theoretical plates) to extract heavy aromatics with furfural. Among them, when extracting the first-line extraction oil, the feed ratio of furfural and raw oil is 1.5:1, and the extraction temperature is controlled at 75°C to obtain light and heavy aromatics and the first raffinate oil (wax oil); the second-line extraction oil raw material During extraction, the feed ratio of furfural to raw oi...

Embodiment 3

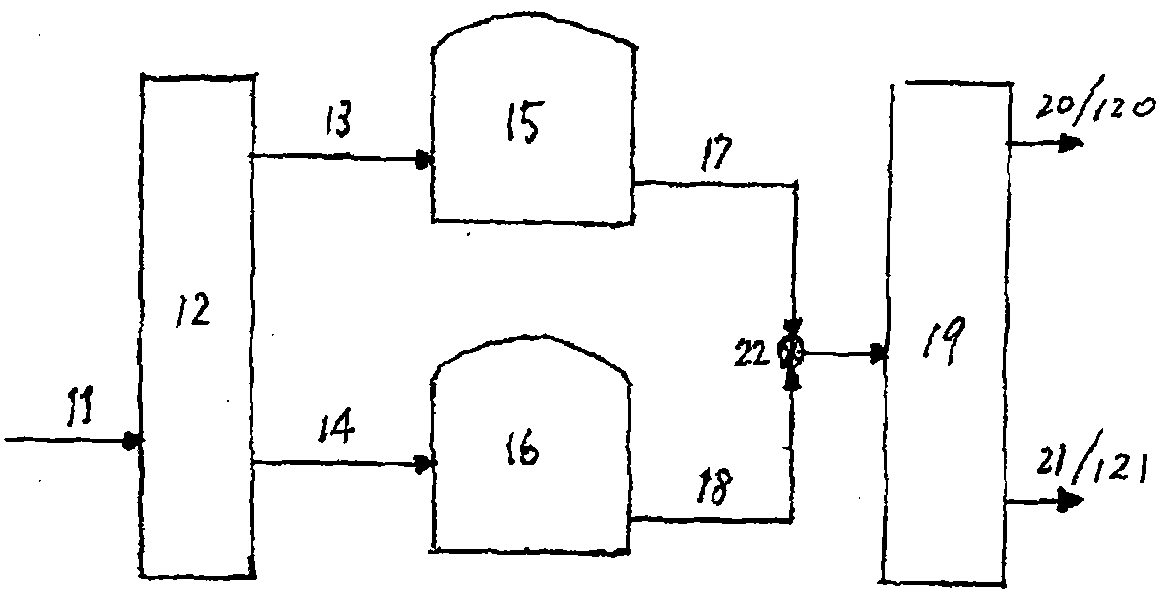

[0069] use as image 3 In the experimental device shown, heavy aromatics were separated from catalytic cracking oil slurry with the amount of catalytic cracking oil slurry feedstock (as shown in Table 1) shown in Table 10. Among them, the catalytic cracking oil slurry is heated to about 380°C, enters a packed tower (vacuum tower) with 16 theoretical trays, and is decompressed and unplugged under a vacuum of 2kPa to separate the 350-450°C minus-line extractor. Oil extraction and 450-500 °C minus second line extraction oil. The two extracted oils are respectively stored in the first buffer tank and the second buffer tank as raw materials for the extraction of heavy aromatics. The oil extracted from the first line is introduced from the first buffer tank as the raw material of the oil extracted from the line to the heavy aromatics extraction device (6 theoretical plates). The ratio of furfural to raw oil is 1.5:1, and the extraction temperature is controlled at 75°C. Obtain lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com