Method for preparing aromatic hydrocarbon and hydrogen-rich fuel gas through catalytic thermal conversion of polyolefin waste plastics

A technology for waste plastics and polyolefins, which is applied in the field of catalytic thermal conversion of polyolefin waste plastics to prepare aromatic hydrocarbons and hydrogen-rich fuel gas, can solve the problems of lack of reasonable use and the difficulty of fuel oil products to meet the requirements of engine operation, so as to reduce catalyst costs and productivity. High, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

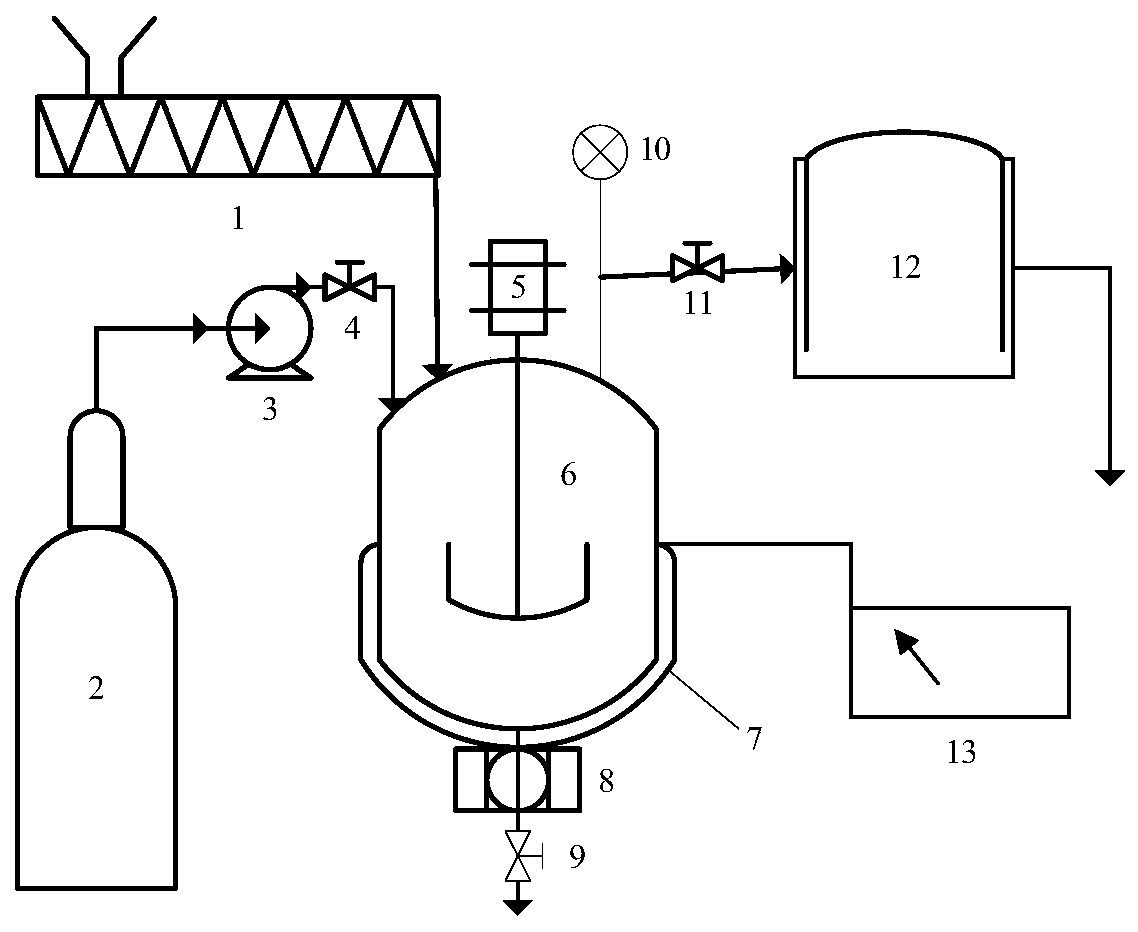

[0025] use as figure 1 As shown in the device, the pretreated polyethylene is fed into the autoclave reactor, and 3wt.% zinc-loaded ZSM-5 is used as the catalyst. The mass ratio of polyethylene raw material to catalyst is 15:1, and nitrogen is purged to remove all After the air in the reactor, close the gas outlet on the reactor, continue to feed nitrogen, make the initial nitrogen pressure to 1bar (that is, no pressurization), close the autoclave reactor, and set the temperature rise rate of the autoclave reactor to 15°C / min, heat the autoclave to 380°C and stop heating. After the autoclave reactor is cooled to normal temperature by air, first open the outlet valve of the autoclave reactor, use the air bag to collect the gas product, then open the reactor outlet valve to collect the liquid product, and the catalyst and solid product are collected by filtering through the filter.

[0026] The 2wt.% zinc-loaded zeolite molecular sieve catalyst is prepared by the following ste...

Embodiment 2

[0046] use as figure 1 The shown device feeds the pretreated polyethylene into the autoclave reactor, adopts 5wt.% zinc-loaded ZSM-5 as a catalyst (the steps of the zinc-loaded zeolite molecular sieve catalyst are the same as in Example 1), and the polyethylene raw material The mass ratio to the catalyst is 10:1. After purging the air in the reactor with nitrogen, close the gas outlet on the reactor, continue to feed nitrogen, and make the initial nitrogen pressure to 10bar, close the autoclave reactor, and the autoclave reactor The heating rate was set at 15°C / min, and the autoclave was heated to 450°C before heating was stopped. After the autoclave reactor is cooled to normal temperature by air, first open the outlet valve of the autoclave reactor to collect the gaseous product, then open the liquid outlet valve of the reactor to collect the liquid product, and the catalyst and solid product are collected by filtering through the filter.

[0047] The mass of liquid and soli...

Embodiment 3

[0052] use as figure 1 The shown device feeds the pretreated polyethylene into the autoclave reactor, and adopts 1wt.% zinc-loaded ZSM-5 as a catalyst (the steps of the zinc-loaded zeolite molecular sieve catalyst are the same as in Example 1), and the polyethylene raw material The mass ratio to the catalyst is 20:1. After purging the air in the reactor with nitrogen, close the gas outlet on the reactor, continue to feed nitrogen, and make the initial nitrogen pressure to 15bar, close the autoclave reactor, and the autoclave reactor The heating rate was set at 15°C / min, and the autoclave was heated to 340°C and then stopped heating. After the autoclave reactor is cooled to normal temperature by air, first open the outlet valve of the autoclave reactor to collect the gaseous product, then open the liquid outlet valve of the reactor to collect the liquid product, and the catalyst and solid product are collected by filtering through the filter.

[0053] The mass of liquid and so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com