Method for preparing aromatic rubber oil

A technology of aromatic rubber oil and aromatic hydrocarbon, which is applied in the field of preparation of aromatic rubber oil to achieve the effect of lowering the pour point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The invention provides a kind of preparation method of aromatic hydrocarbon rubber oil, and the method comprises the following steps:

[0015] (1) Fully contacting the raw material oil with the extraction solvent to obtain the first extract and the first raffinate, wherein the raw oil is solvent refined extraction oil, and the extraction solvent contains a main solvent and a first anti-solvent , and the content of the main solvent in the extraction solvent is greater than the content of the first anti-solvent;

[0016] (2) Fully contacting the first extract with the second anti-solvent to obtain a second raffinate and a second extract;

[0017] (3) reclaim solvent from described second raffinate, obtain aromatic hydrocarbon rubber oil;

[0018] Wherein, the solubility of aromatic hydrocarbons in the main solvent is greater than the solubility of alkanes in the anti-solvent, the solubility of aromatic hydrocarbons or alkanes in the anti-solvent is less than the solubili...

Embodiment 1

[0046] This embodiment is used to illustrate the preparation method of aromatic rubber oil provided by the present invention.

[0047] The extracted oil obtained from the light deoiling of intermediate base crude oil through solvent refining is used as the raw material oil (see Table 1 for the properties of the raw material oil), and is contacted with the extraction solvent in a glass three-necked flask (3000mL) for the first extraction. The extraction solvent and The total feed amount of raw material oil is 1500g.

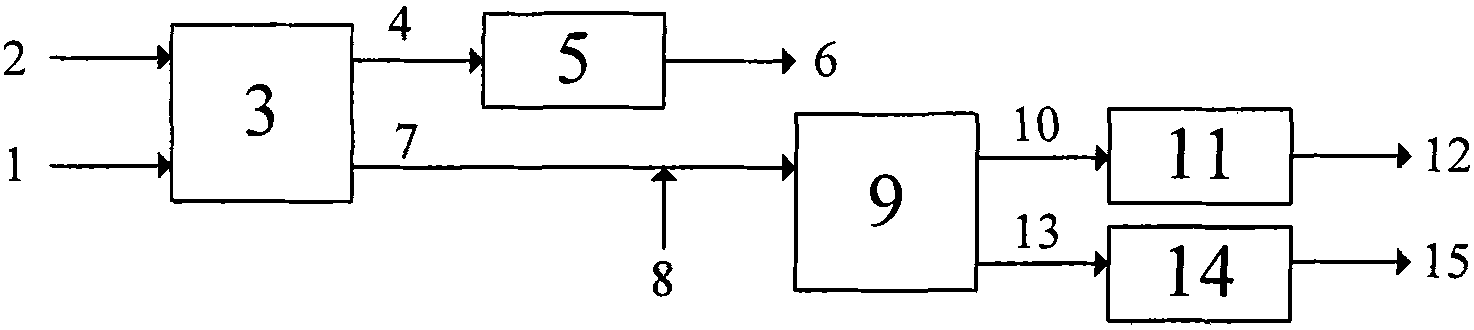

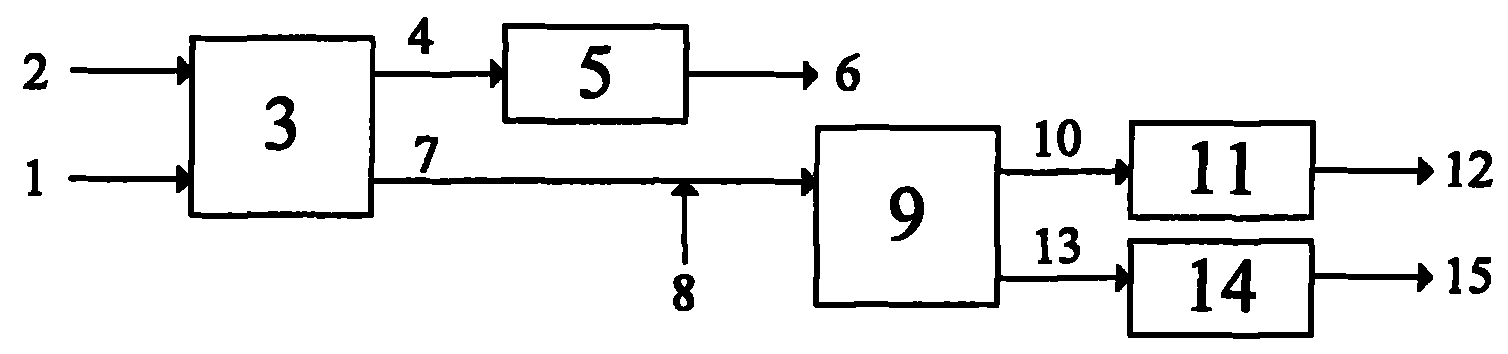

[0048] according to figure 1 Process for solvent extraction to produce aromatic rubber oil. The contact condition of extraction solvent and stock oil is: take furfural and water as extraction solvent (in the extraction solvent, each component weight percentage is: furfural 98.0% by weight, water 2.0% by weight), and the agent-oil ratio is 3.0: 1 (the weight ratio of extraction solvent to raw oil, the same below), the contact temperature is 85°C, the contact time...

Embodiment 2

[0053] This embodiment is used to illustrate the preparation method of aromatic rubber oil provided by the present invention.

[0054] Solvent extraction is carried out on the same extraction device as in Example 1 to prepare aromatic rubber oil, and the oil extracted from the fourth-line solvent-refined intermediate base crude oil is used as the raw material oil. The properties of the raw material oil are shown in Table 1. The extraction solvent and the raw material oil The total feed amount was 1500 g.

[0055] according to figure 1 Process for solvent extraction to produce aromatic rubber oil. The extraction conditions are: taking N-methylpyrrolidone and water as the extraction solvent (the weight percentage of each component in the extraction solvent is: N-methylpyrrolidone 96.0% by weight, water 4.0% by weight), and the agent-oil ratio is 2.0:1, the contact temperature is 63°C, the contact time is 30 minutes, the settling temperature is 63°C, and the settling time is 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com