Water-borne sound-insulating damping coating for ship and preparation method thereof

A damping coating, water-based technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of sound insulation performance, construction, flame retardancy, drying adhesion defects, inability to meet marine materials and other problems, and achieve good flame retardant performance , the effect of good damping, high damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

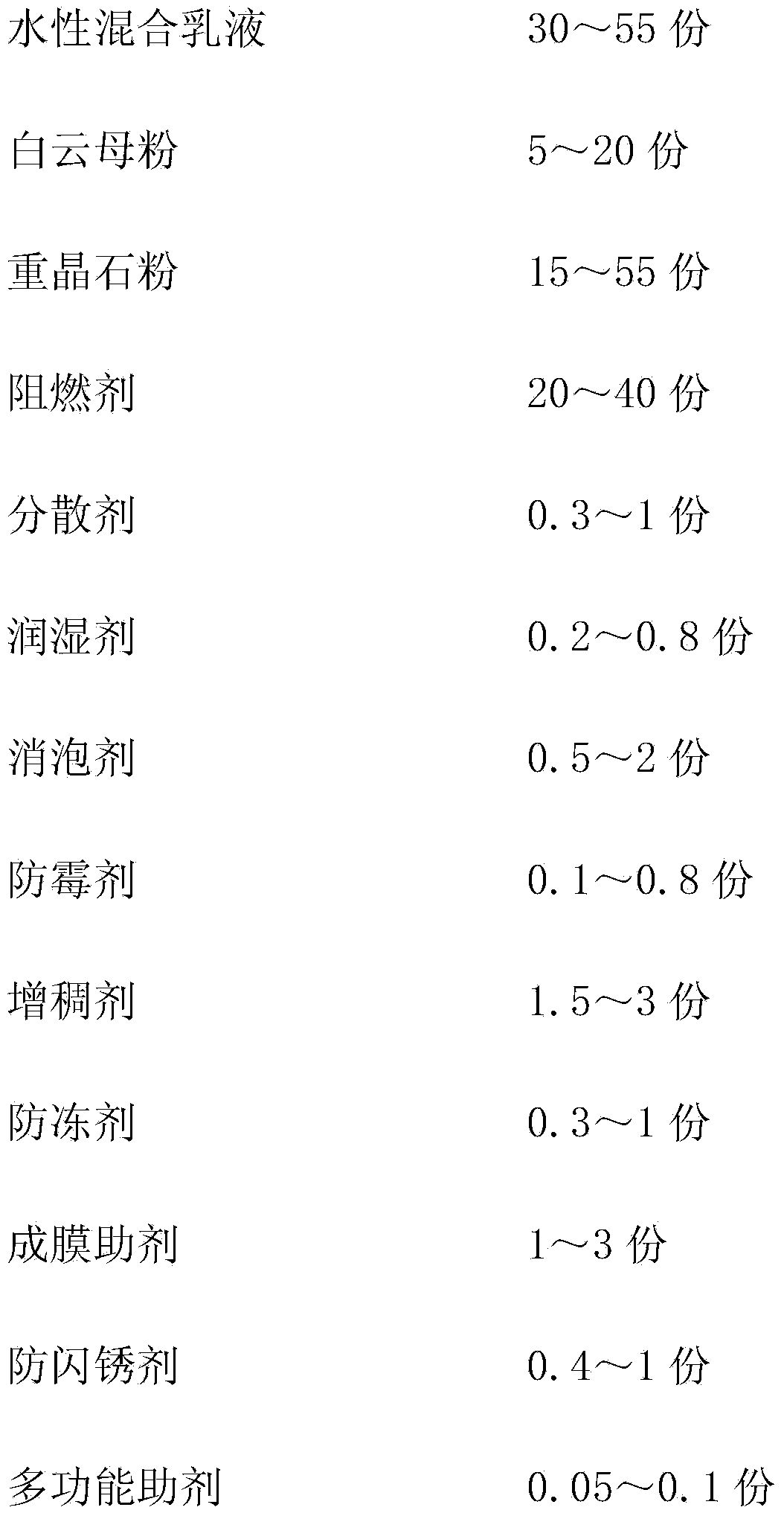

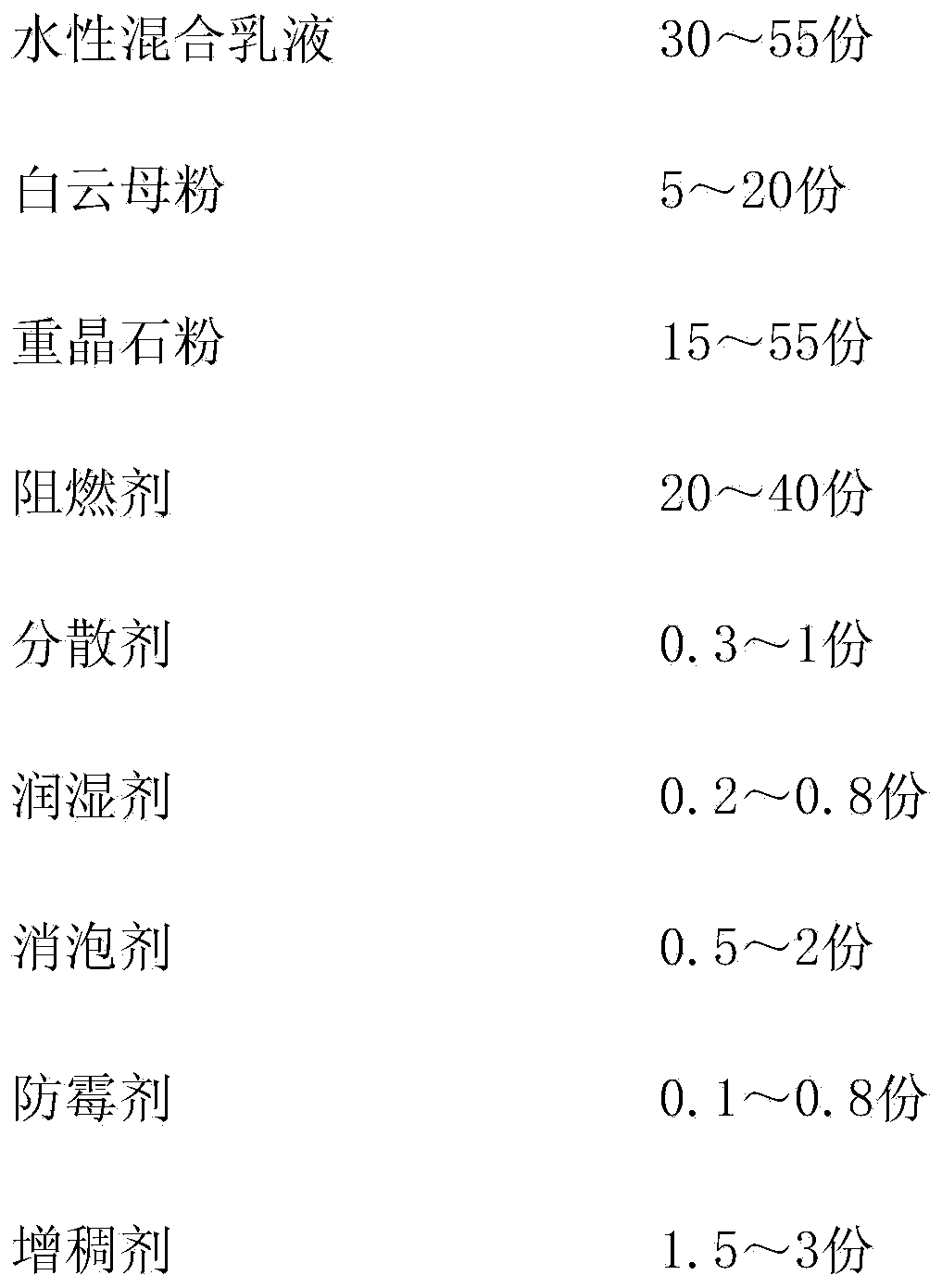

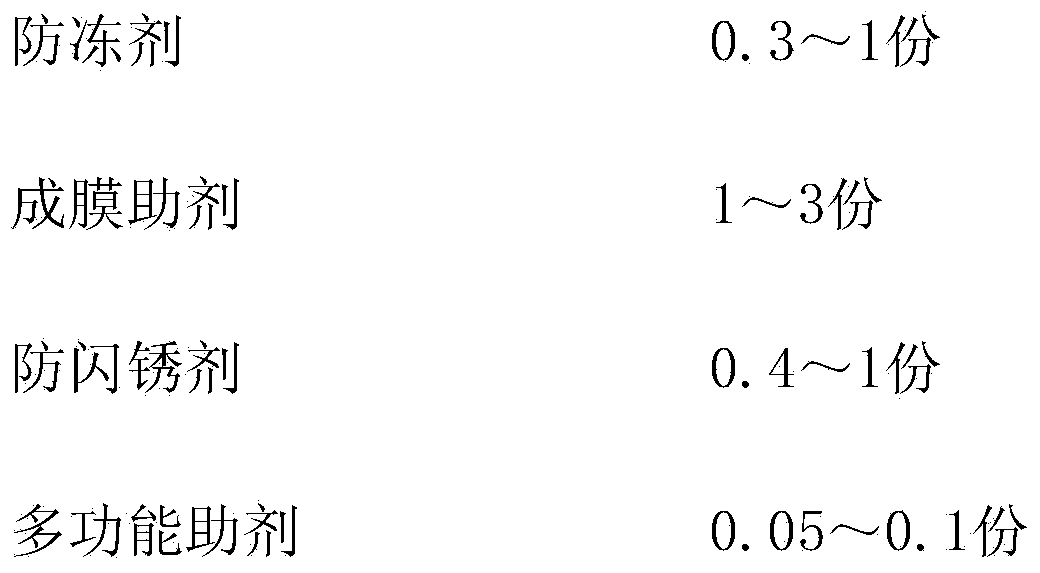

[0028]The main components of the water-based sound-insulating and damping coating for ships in the normal temperature region of this embodiment are proportioned according to the following weight ratios: 40 parts of water-based emulsion; 4 parts of muscovite powder with a particle size of 40 mesh; 6 parts of muscovite powder with a particle size of 100 mesh; 25 parts Barite powder with a particle size of 325 meshes; 20 parts of aluminum hydroxide; 5 parts of copper oxide;

[0029] 1.5 parts of Taxanol film-forming aid, the Taxanol film-forming aid used in the present invention comes from American Eastman Company.

[0030] The method for preparing the normal temperature water-based marine sound insulation and damping coating of the present embodiment may further comprise the steps:

[0031] (1) Preparation of water-based emulsion:

[0032] At room temperature, mix 30 parts of water-based styrene-acrylic emulsion with a glass transition temperature of 10°C and 10 parts of water-...

Embodiment 2

[0039] The main components of the water-based sound-insulating and damping coating for ships in the normal temperature region of this embodiment are proportioned according to the following weight ratios: 50 parts of water-based emulsion; 6 parts of muscovite powder with a particle size of 40 mesh; 18 parts of barite powder with a particle size of 200 mesh; 15 parts Aluminum hydroxide; 10 parts of antimony trioxide; 6 parts of copper oxide; 2.5 parts of Taxanol film-forming aid. The Taxanol film-forming aid used in the present invention comes from Eastman Corporation of the United States.

[0040] The method for preparing the normal temperature water-based marine sound insulation and damping coating of the present embodiment may further comprise the steps:

[0041] (1) Preparation of water-based emulsion:

[0042] At room temperature, mix 35 parts of water-based styrene-acrylic emulsion with a glass transition temperature of 10°C and 15 parts of water-based emulsion with a glas...

Embodiment 3

[0049] The main components of the water-based sound-insulating and damping coating for ships in the normal temperature region of this embodiment are proportioned according to the following weight ratios: 40 parts of water-based emulsion; 4 parts of muscovite powder with a particle size of 40 mesh; 6 parts of muscovite powder with a particle size of 100 mesh; 26 parts The particle size is 325 mesh barite powder; 10 parts of aluminum hydroxide; 10 parts of magnesium hydroxide; 4 parts of copper oxide;

[0050] The method for preparing the normal temperature water-based marine sound insulation and damping coating of the present embodiment may further comprise the steps:

[0051] (1) Preparation of water-based emulsion:

[0052] At room temperature, 25 parts of water-based styrene-acrylic emulsion with a glass transition temperature of 5°C and 15 parts of water-based emulsion with a glass transition temperature of 45°C were uniformly mixed, and the water-based emulsion was obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com