Preparing technology for human immune globulin

A technology of human immunoglobulin and preparation process, which is applied in the field of blood products, can solve the problems of immunoglobulin loss and other problems, and achieve the effect of simple steps, reduced loss, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Prepare rabies patient immunoglobulin by the present invention

[0020] (1) Plasma thawing: Melt 100 servings of raw plasma with a rabies surface antibody titer ≥ 8IU / mL at 0-4°C;

[0021] (2) Separation of components Ⅰ+Ⅱ+Ⅲ from plasma: Dilute the plasma with 0.1mol / L NaCl solution, the dilution end point is that the protein content is 4.5%~5.5%, and then adjust the plasma pH with pH 4.0 acetate buffer 5.50~6.00, cool down to below 0°C and start spraying 95% ethanol below -15°C, so that the final ethanol concentration of the reaction solution reaches 25% (v / v), and the final temperature of the product is controlled at -2.0~-3.0°C, continue to stir for 2 After 1 hour, add diatomite and use a filter press to filter under pressure. The maximum liquid inlet pressure should not exceed 0.20Mpa, and press filter to obtain components Ⅰ+Ⅱ+Ⅲ;

[0022] (3) The first step of chromatography: dissolve the components I+II+III obtained in step (2) with NaCl solut...

Embodiment 2

[0028] Example 2: The process steps of preparing hepatitis B human immunoglobulin, tetanus human immunoglobulin and anti-D human immunoglobulin by this method are the same as those in Example 1.

Embodiment 3

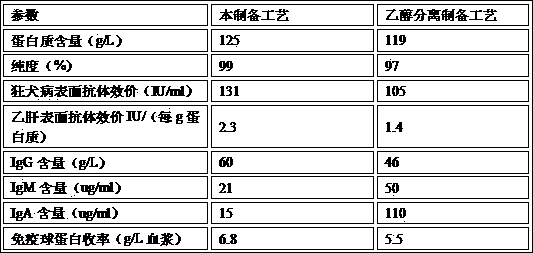

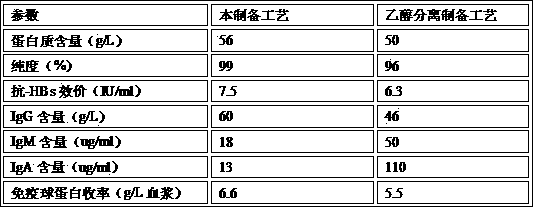

[0029] Embodiment 3: Comparison of product parameters between the preparation process of the present invention and the traditional ethanol multi-stage separation preparation process:

[0030] rabies immunoglobulin

[0031]

[0032] Hepatitis B Human Immunoglobulin

[0033]

[0034] It can be seen from the table that the quality and yield of human immunoglobulin prepared by this process are better than those prepared by traditional ethanol multistage separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com