Anti-bacterial plastic bottle cap where laser printing can be conducted, and manufacturing process of anti-bacterial plastic bottle cap

An antibacterial plastic and manufacturing process technology, applied in the field of antibacterial plastic bottle caps and its manufacturing process, can solve the problems of beverage products such as low temperature resistance, poor absorption, and precipitation of low molecular substances, so as to be beneficial to environmental protection and avoid secondary pollution , long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

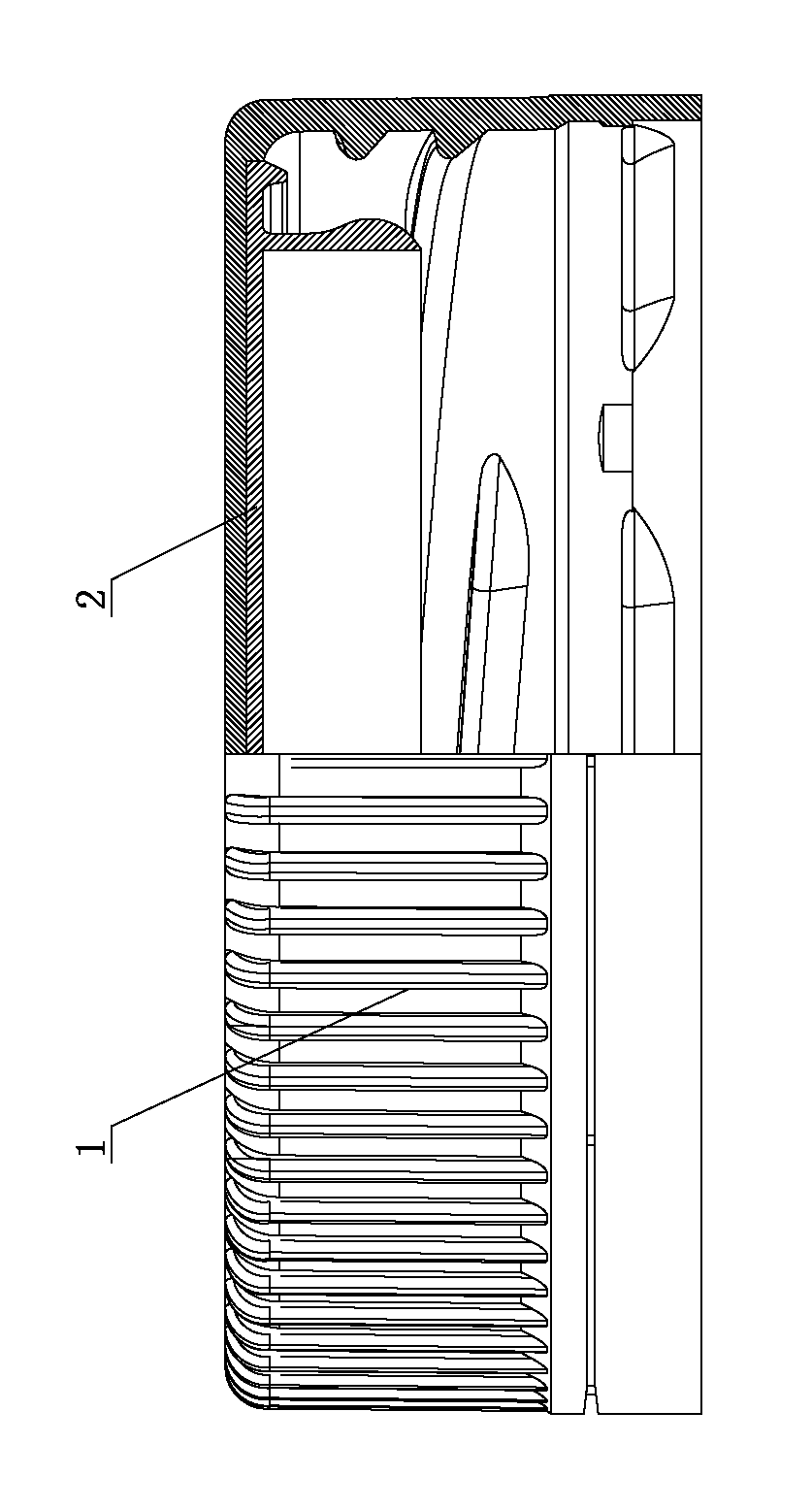

[0049] like figure 1 As shown, a laser-printable antibacterial plastic bottle cap includes an antibacterial plastic outer cover 1 and a sealing inner pad 2, the antibacterial plastic outer cover 1 is made of ABS antibacterial plastic, and the antibacterial plastic outer cover 1 and sealing inner pad 2 pass Hot-melt adhesive fixation;

[0050] Described ABS antibacterial plastic is made up of following weight ratio raw material:

[0051] ABS material: 90

[0052] KH-550 coupling agent: 1.5

[0053] Silver-loaded inorganic antibacterial agent: 75

[0054] Polyethylene wax dispersant: 1.8

[0055] Stearic acid lubricant: 1.8

[0056] Antioxidant (ethylene-octene copolymer): 1.7;

[0057] The production material of the sealing inner pad 2 is composed of polyethylene and aluminum-based laser powder, which is calculated in parts by weight: polyethylene: 100

[0058] Aluminum-based laser powder: 2.0.

[0059]The mechanical properties of the ABS plastic are highly recognized b...

Embodiment 1

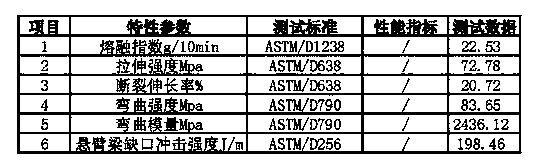

[0062] For the detection experiment result of ABS antibacterial plastic in embodiment one:

[0063]

[0064] The manufacturing process of the above-mentioned laser-printable antibacterial plastic bottle cap comprises the following steps:

[0065] A. Mix polyethylene and aluminum-based laser powder in proportion;

[0066] B. Pass the mixture obtained in step A through a twin-screw extruder at 160-180°C with a melting pressure in the range of 1.5-2.5 MPa, and then inject to obtain the sealing inner gasket 2;

[0067] C. Dry mix various raw materials of ABS antibacterial plastics in a high-speed mixer for 6 to 9 minutes, and then put them in a twin-screw extruder to make a masterbatch through melt extrusion, cooling, and pelletizing. Among them, the twin-screw extruder The temperature of the first area of the machine is 165-170 °C, the second area is 175-180 °C, the third area is 200-220 °C, the fourth area is 215-220 °C; the fifth area is 210-215 °C, and the residence time...

Embodiment 2

[0072] A laser-printable antibacterial plastic bottle cap includes an antibacterial plastic outer cover 1 and a sealing inner pad 2, the antibacterial plastic outer cover 1 is made of ABS antibacterial plastic, and the antibacterial plastic outer cover 1 and sealing inner pad 2 are bonded by hot melting Knot fixed;

[0073] Described ABS antibacterial plastic is made up of following weight ratio raw material:

[0074] ABS raw material: 105

[0075] KH-550 coupling agent: 2.0

[0076] Silver-loaded inorganic antibacterial agent: 80

[0077] Polyethylene wax dispersant: 2.1

[0078] Stearic acid lubricant: 2.1

[0079] Antioxidant (ethylene-octene copolymer): 2.2;

[0080] The material for the sealing inner pad 2 is composed of polyethylene and aluminum-based laser powder, which are calculated in parts by weight: polyethylene: 100, aluminum-based laser powder: 4.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com