Flue gas SNCR (selective non-catalytic reduction) denitration control device and method

A control method and flue gas technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as increased NOX emissions, incomplete reactions, and secondary pollution, achieving good results, improving efficiency, and reducing The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

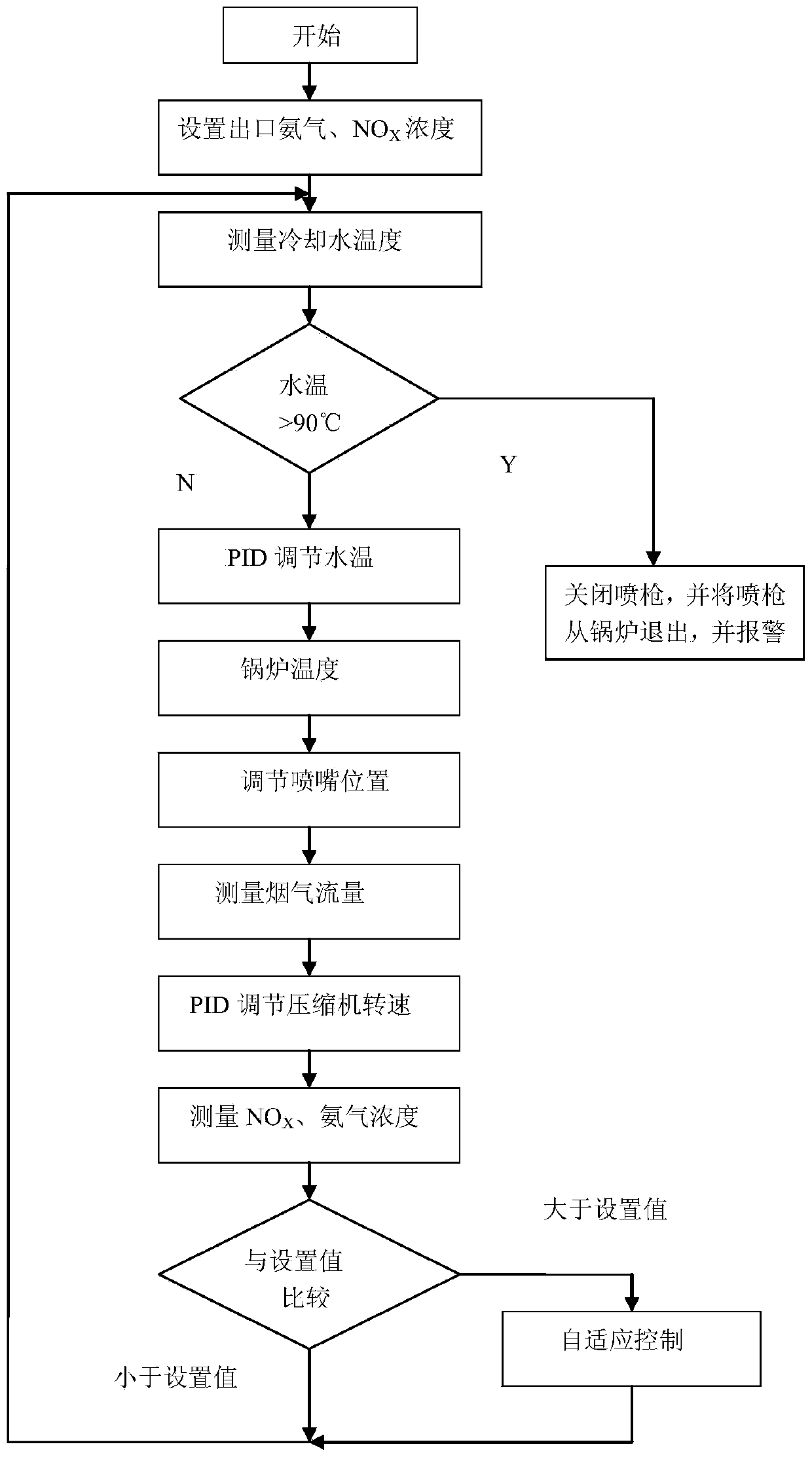

Method used

Image

Examples

Embodiment 1

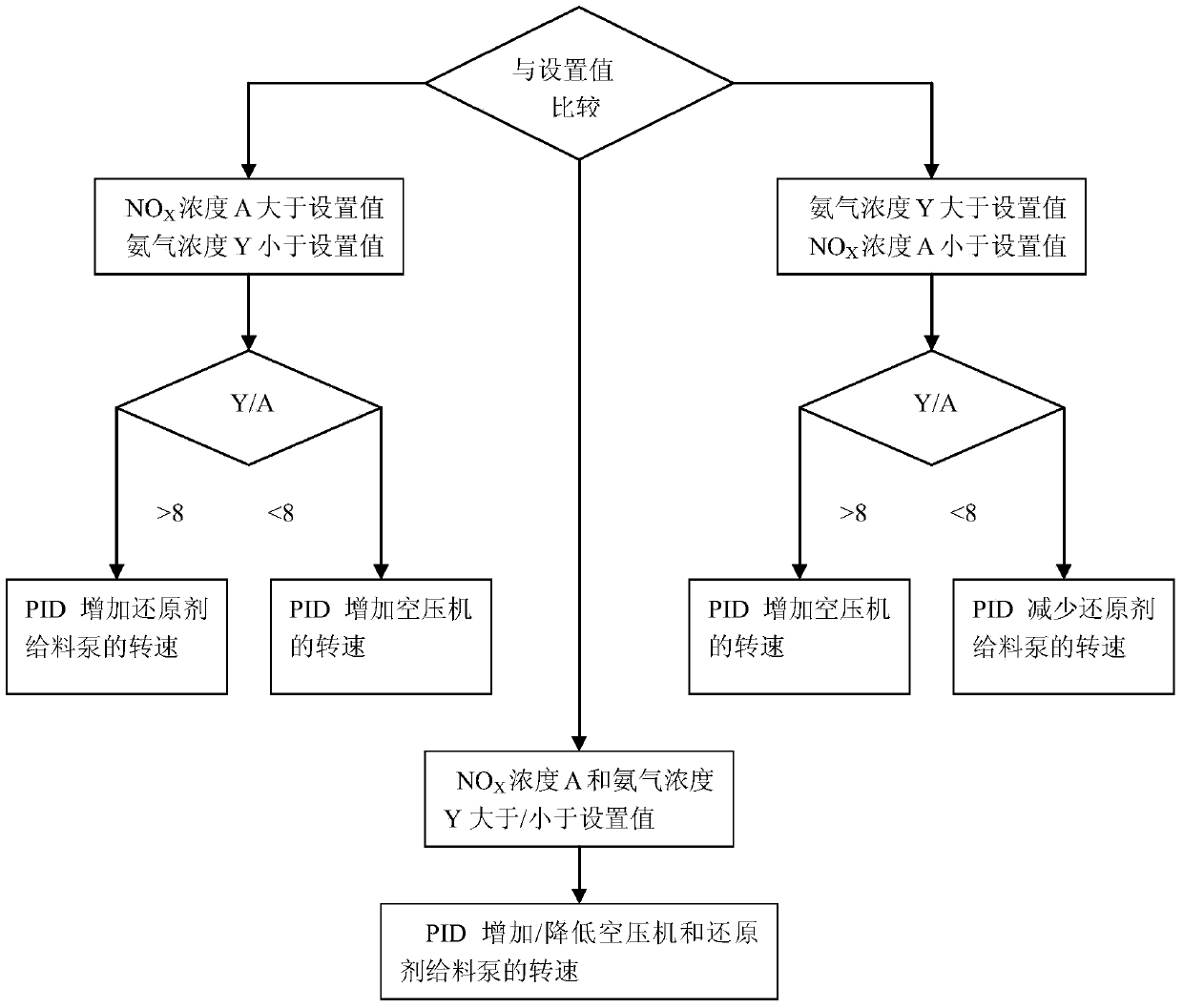

[0062] Embodiment 1: a kind of flue gas denitrification SNCR device, the ammonia gas concentration requirement of setting its outlet is 10ppm, and the NO of outlet X The concentration requirement is 80ppm. The ammonia gas concentration Y at the outlet measured by the sensor is 9ppm, and the NO at the outlet X Concentration A is 100 ppm. According to the adaptive control system, A / Y is greater than the set value of 8. The automatic PID control of the PLC controller increases the speed of the reductant feed pump to make the NO X The outlet concentration meets the setting requirements.

Embodiment 2

[0063] Embodiment 2: a kind of flue gas denitrification SNCR device, the ammonia gas concentration requirement at its outlet is set to be 10ppm, and the NO at the outlet X The concentration requirement is 70ppm. The ammonia gas concentration Y at the outlet measured by the sensor is 9ppm, and the NO at the outlet X Concentration A was 80 ppm. According to the adaptive control system, A / Y is less than the set value 8. The automatic PID control of the PLC controller increases the speed of the air compressor to make the NO X The outlet concentration meets the setting requirements.

Embodiment 3

[0064] Embodiment 3: A kind of flue gas denitrification SNCR device, the ammonia gas concentration requirement at its outlet is set to be 10ppm, and the NO at the outlet X The concentration requirement is 80ppm. The ammonia concentration at the outlet measured by the sensor is 18ppm, and the NO at the outlet X The concentration is 60ppm. According to the adaptive control system, if A / Y is less than the set value of 8, the system calculates the automatic PID control of the PLC controller to reduce the speed of the reducing agent feeding pump to prevent ammonia gas from escaping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com