Efficient double-cavity turbulent heat exchanger

A heat exchanger and turbulent flow technology, applied in the field of heat exchange equipment, can solve the problems of high maintenance cost, complex process, low heat exchange efficiency, etc., and achieve the effects of reasonable equipment structure, high heat transfer efficiency, and heat exchange area saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

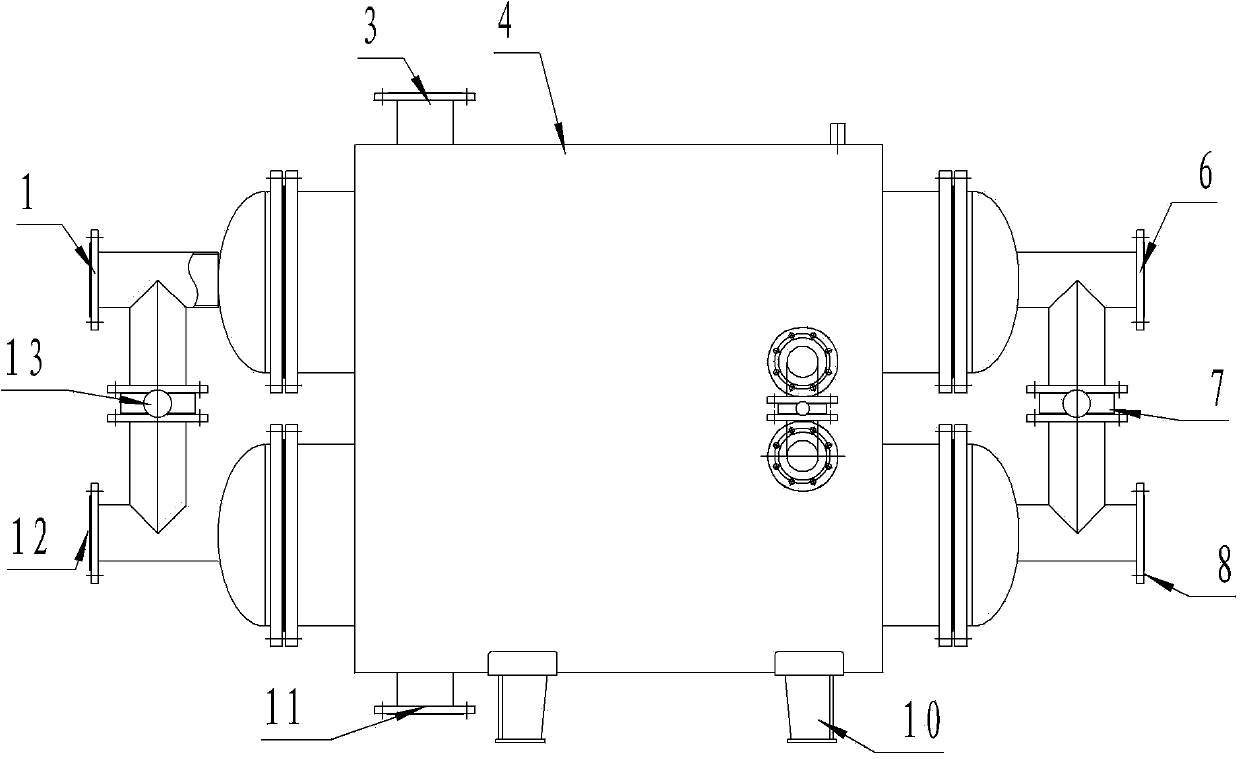

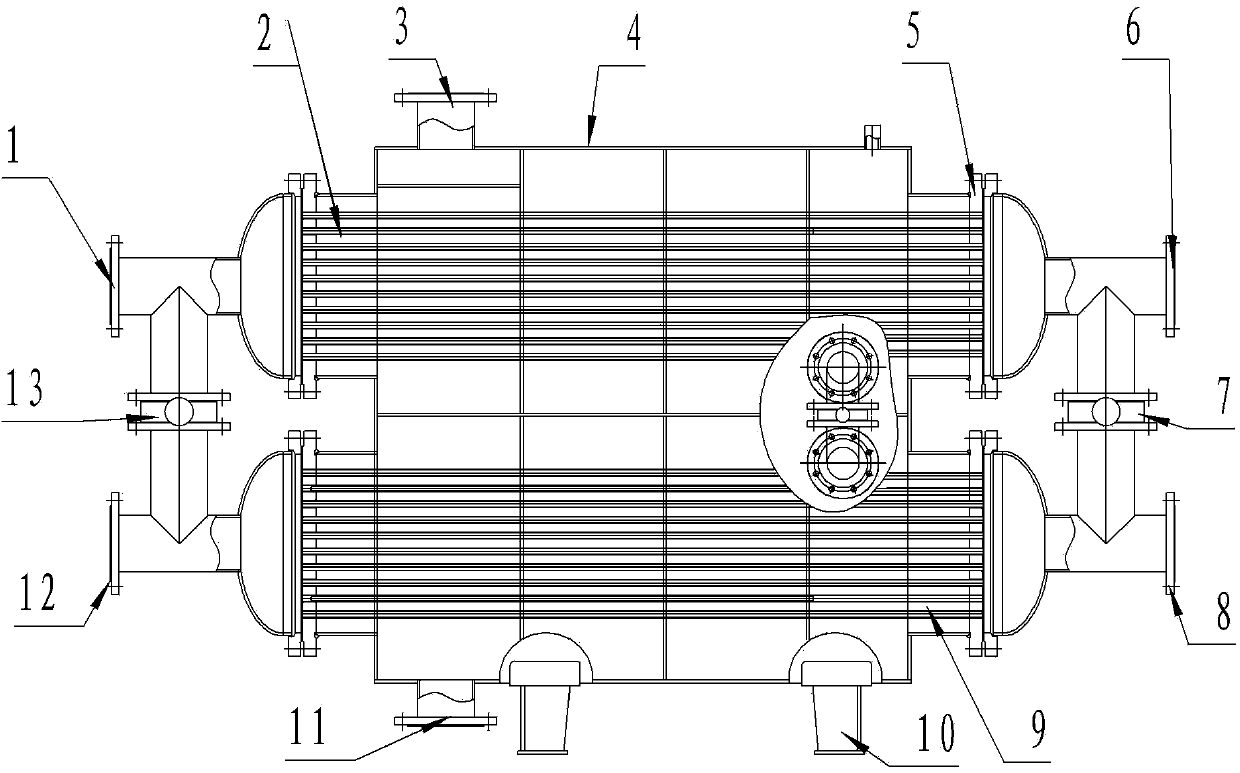

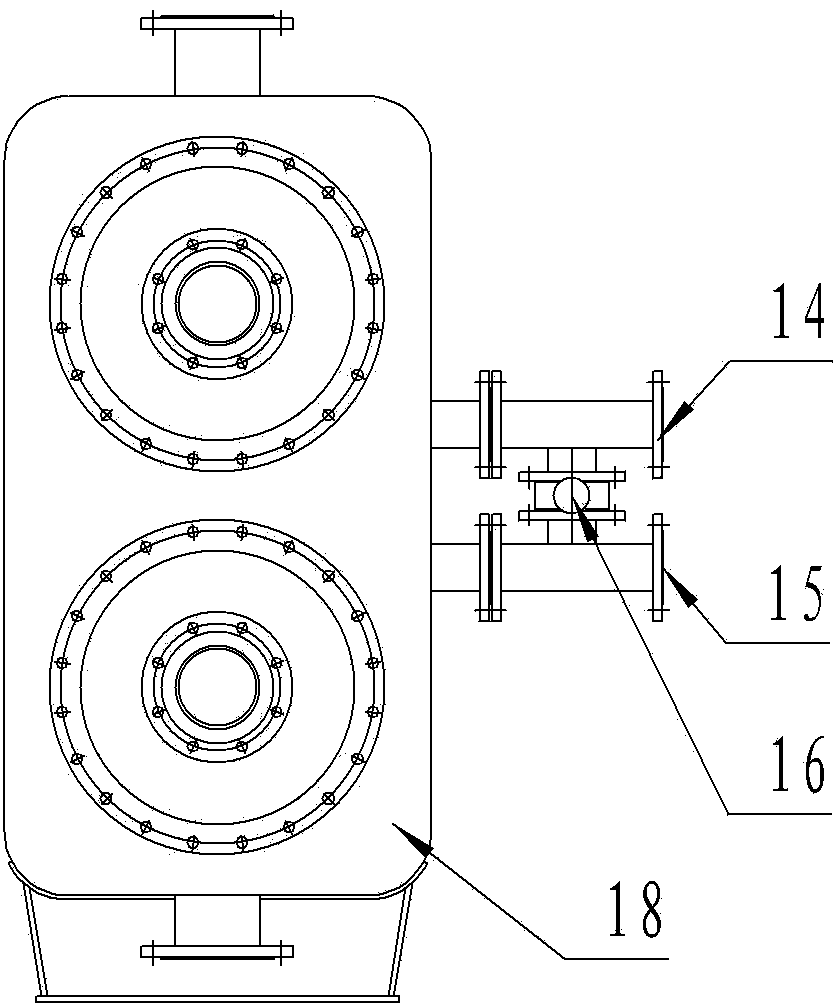

Embodiment 1

[0021] Embodiment 1, a high-efficiency double-chamber turbulent heat exchanger, including a heat exchanger cylinder 4 equipped with a primary heat medium inlet and a secondary heat medium inlet and outlet, and a heat exchange tube bundle installed in the cylinder. It is characterized in that: The cylinder described above is a rectangular cylinder, and the double-chamber partition 17 in the middle of the rectangular cylinder divides the cylinder into upper and lower chambers. Tube bundle 9, rectangular blocking plates 18 are installed at both ends of the cavity, and circular tube sheets 5 are respectively arranged on the blocking plates. The inlet and outlet of the secondary heat medium are respectively set on the upper and lower chambers at the same end, and a connection switch is provided between the inlet and outlet of the secondary heat medium of the upper and lower chambers at the same end, that is, the secondary double-cavity connection switch 13 at the front end and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com