Solar cooking equipment

A solar energy and equipment technology, applied in solar thermal power generation, solar thermal devices, silk reeling, etc., can solve the problems of low labor efficiency, unscientific design, hidden dangers in production safety, etc., achieving remarkable energy saving effect, simple and effective structure, The effect of high-efficiency cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

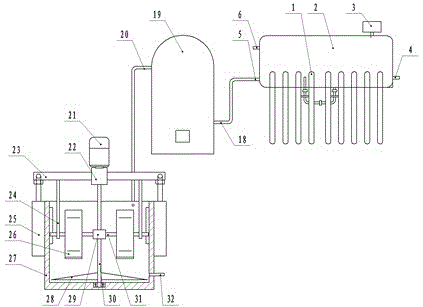

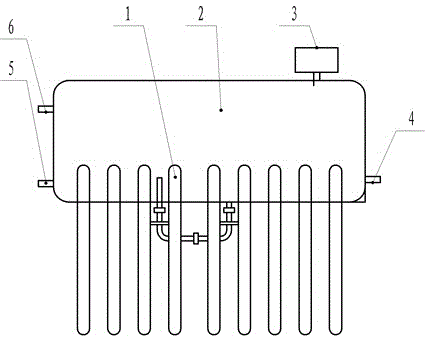

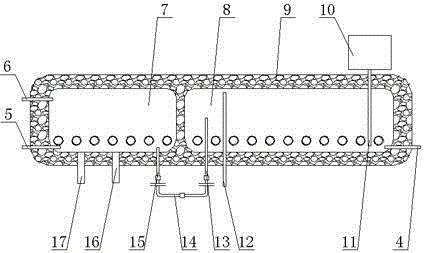

[0029] The structure of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0030] as attached Figure 1~2As shown, the solar energy cotton boiling equipment of the present invention includes a heat collecting tube 1, a water storage tank 2, an automatic water replenisher 3, a sewage outlet 4, a water outlet 5, a water level and a temperature detection hole 6, a small water tank 7, a large water tank 8, and an insulation layer 9. Automatic water supply tank 10, water supply pipe 11, overflow or exhaust hole 12, large water tank connection 13, external connection pipe 14, small water tank connection 15, electric heating spare hole 16, temperature detection spare hole 17, boiler water inlet 18. Boiler 19, boiler water outlet 20 and cotton boiling body 27, water storage tank 2 is connected to heat collecting pipe 1, water outlet 5 of water storage tank 2 is connected to boiler water inlet 18, boiler water outlet 20 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com