A low-carbon equivalent high-strength hot-rolled seamless line pipe and its manufacturing method

A technology of seamless line pipe and manufacturing method, which is applied in the direction of metal rolling, etc., can solve the problems of lack of general significance, high cost of heat treatment, large difference in structure of pipe body/weld area, etc., and achieve stable welding performance and low C Equivalent, high strength and toughness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

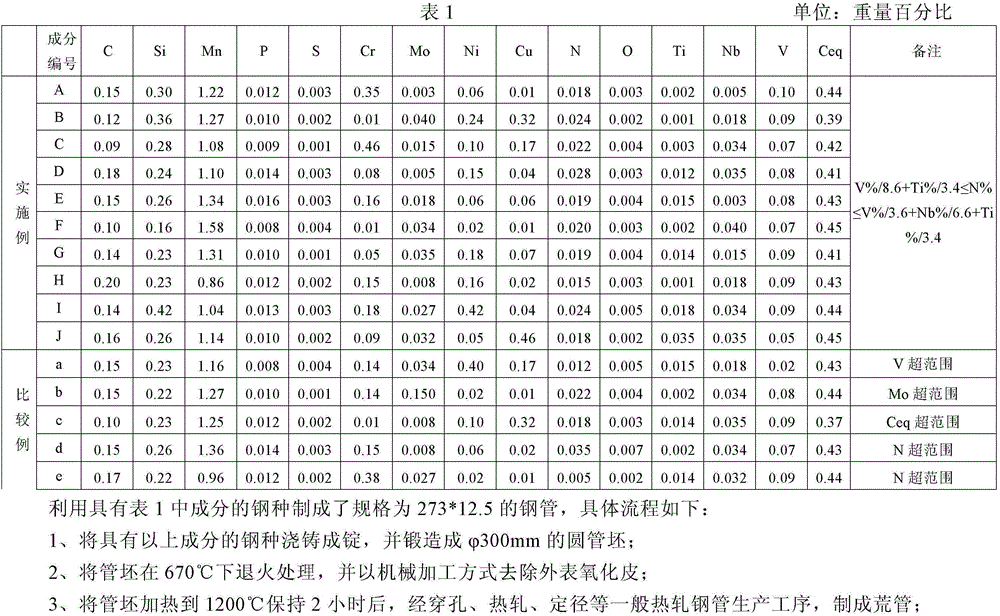

[0055] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention.

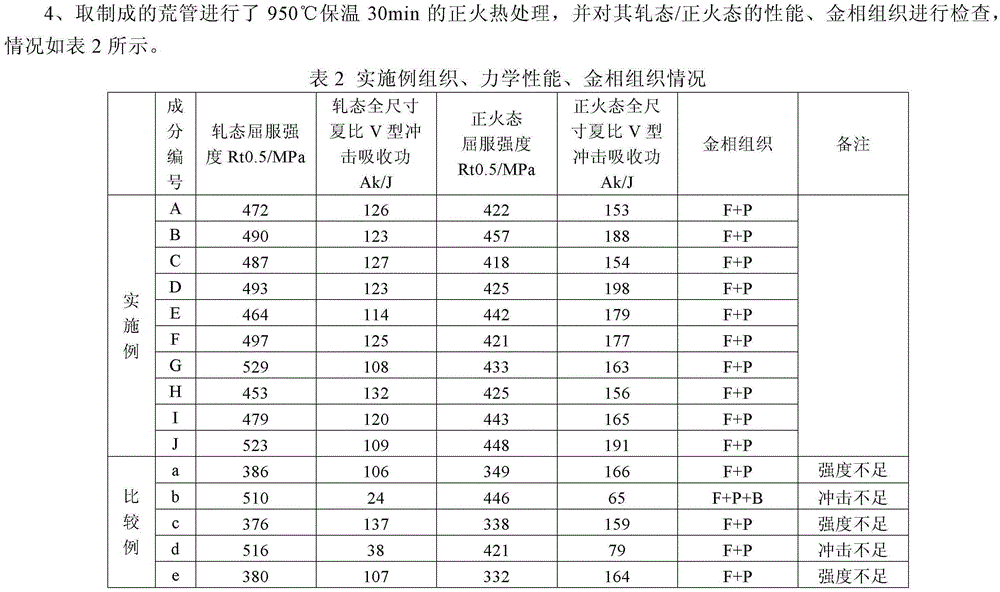

[0056] Table 1 is the embodiment of the present invention, and Table 2 is the performance of the embodiment of the present invention.

[0057]

[0058]

[0059] The yield strength data is obtained by processing the steel pipe into an API arc sample, and taking the average after testing according to the API standard

[0060] The data of full-size Charpy V-shaped impact absorption energy is obtained by taking a full-size V-shaped impact sample with a cross-sectional area of 10*10*55 on the manufactured steel pipe, and taking the average after inspection according to GB / T229 standard;

[0061] The metallographic structure is obtained by taking a full-thickness sample from the sample tube, grinding and polishing it, corrodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com