Manufacturing technology for nitrogen-containing hard alloy

A technology of cemented carbide and manufacturing process, applied in the field of nitrogen-containing cemented carbide manufacturing process, can solve the problems of difficult mass industrial production, no mass production, poor wettability, etc., to reduce production costs and achieve excellent alloy performance. , the effect of solving the scarcity of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

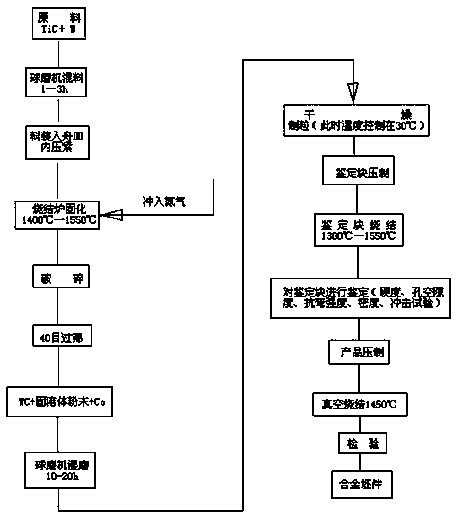

[0028] As an embodiment of the present invention, such as figure 1 As shown, a nitrogen-containing cemented carbide manufacturing process, using W, TiC, N 2 As a raw material, after being fully mixed, the following reaction occurs at high temperature:

[0029] 2W+C+TiC+N—→2WC+TiN

[0030] W captures C in TiC to form WC, and free Ti and N form TiN to form a TiCN solid solution. WC dissolves on the surface of TiCN solid solution particles, and the solid solution is made into a solid solution powder, and then the solid solution powder is added to WC and Co to form an alloy. .

[0031] As preferably, the specific process step of preparing solid solution powder is:

[0032] (1) Mix W and TiC thoroughly in a mixer, then put them into a graphite boat and compact them;

[0033] (2) Put the raw material treated in step (1) into the sintering furnace, heat it to 1400°C in vacuum, and keep it warm for 30 minutes to make W generate WC, then continue to heat up to 1550°C, and fill it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com