High-antimony bismuth-containing material treatment technology

A processing technology and material technology, applied in the processing technology field of high antimony and bismuth-containing materials, can solve the problems of high time consumption, high cost and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

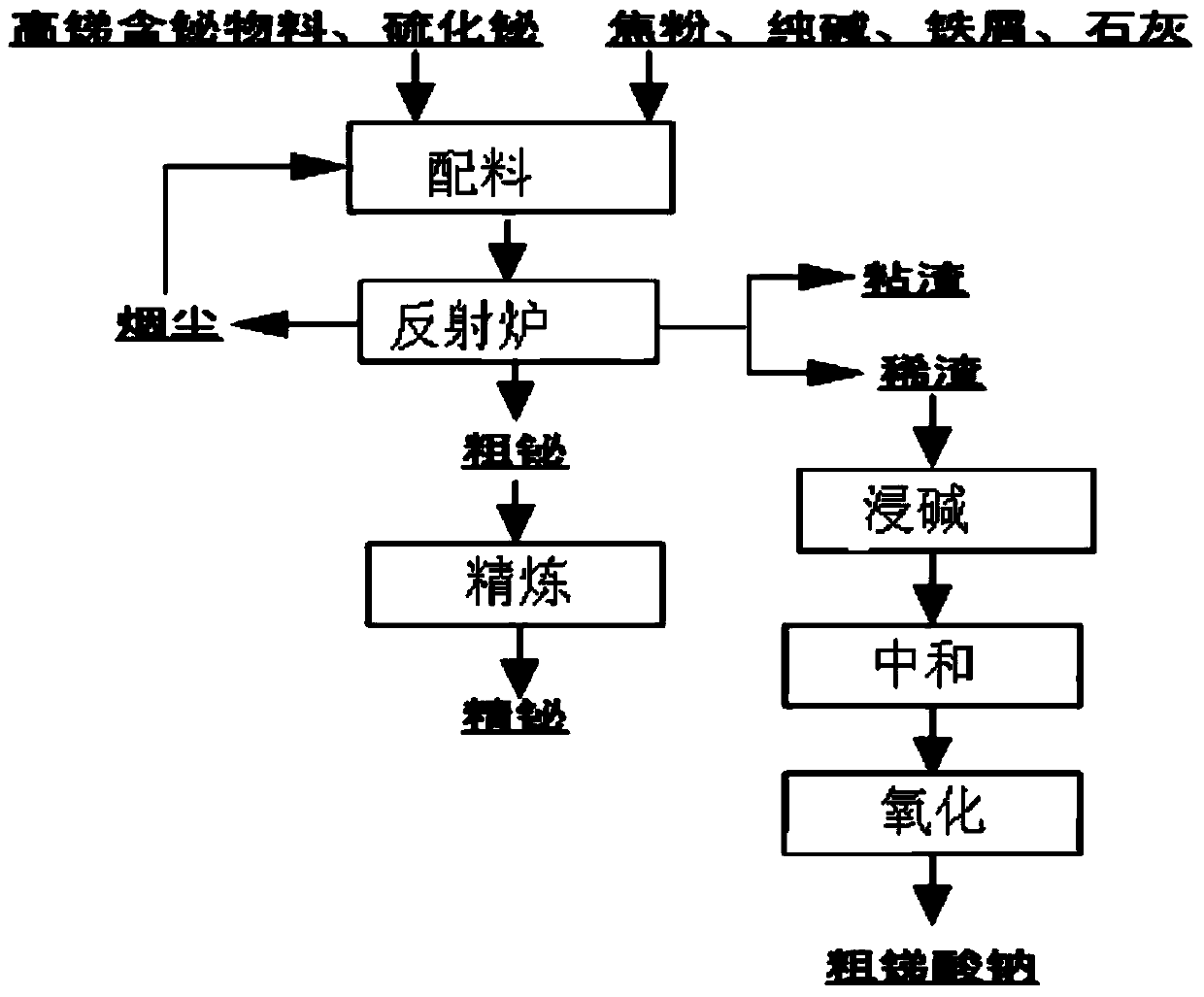

Method used

Image

Examples

Embodiment 1

[0024] (1) Reverberatory furnace reduction smelting process

[0025] The high-antimony bismuth-containing material mainly contains Sb and a small amount of Cu impurity elements. The high-antimony bismuth-containing material and bismuth sulfide are mixed evenly, and then added to the reverberatory furnace together with lime, soda ash, iron filings and coke powder for reduction smelting. 500°C and smelting time of 2 hours. After the smelting is over, remove the slag to obtain thick bismuth, thin slag and sticky slag for later use; wherein, the amount of bismuth sulfide added is 20% by mass of the high-antimony bismuth-containing material, and the lime The addition accounts for 8% of the mass percentage of high antimony and bismuth-containing materials, the addition of said soda ash accounts for 20% of the mass percentage of high antimony and bismuth-containing materials, and the addition of said iron filings accounts for 5% of the mass percentage of high antimony and bismuth-cont...

Embodiment 2

[0039] (1) Reverberatory furnace reduction smelting process

[0040] The high-antimony bismuth-containing material mainly contains Sb and a small amount of Cu impurity elements. The high-antimony bismuth-containing material and bismuth sulfide are mixed evenly, and then added to the reverberatory furnace together with lime, soda ash, iron filings and coke powder for reduction smelting. 600°C, smelting time of 8 hours, after the smelting, remove the slag, obtain thick bismuth, thin slag and sticky slag, and set aside; wherein, the added amount of the bismuth sulfide accounts for 15% of the mass percentage of the high-antimony bismuth-containing material, and the lime Addition accounted for high antimony bismuth material mass percentage is 5%, said soda ash addition accounts for high antimony bismuth material mass percentage is 10%, said iron filings addition accounts for high antimony bismuth material mass percentage is 2.5%; Melting After finishing, the slag is removed to obta...

Embodiment 3

[0054] (1) Reverberatory furnace reduction smelting process

[0055] The high-antimony bismuth-containing material mainly contains Sb and a small amount of Cu impurity elements. The high-antimony bismuth-containing material and bismuth sulfide are mixed evenly, and then added to the reverberatory furnace together with lime, soda ash, iron filings and coke powder for reduction smelting. 700°C and smelting time of 12 hours. After the smelting is over, remove the slag to obtain thick bismuth, thin slag and sticky slag for later use; wherein, the amount of bismuth sulfide added is 10% by mass of the high-antimony bismuth-containing material, and the lime The addition amount accounts for 3% of the mass percentage of high antimony and bismuth-containing material, the addition of said soda ash accounts for 5% of the mass percentage of high antimony and bismuth-containing material, and the addition of said iron filings accounts for 1% of the mass percentage of high antimony and bismuth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com