A kind of polypropylene heterophasic copolymer resin with high rubber content that can be used for 3D printing and its preparation method and application

A technology of 3D printing and rubber content, applied in the field of polypropylene heterophasic copolymer resin, can solve rare problems, achieve excellent performance, expand application range, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

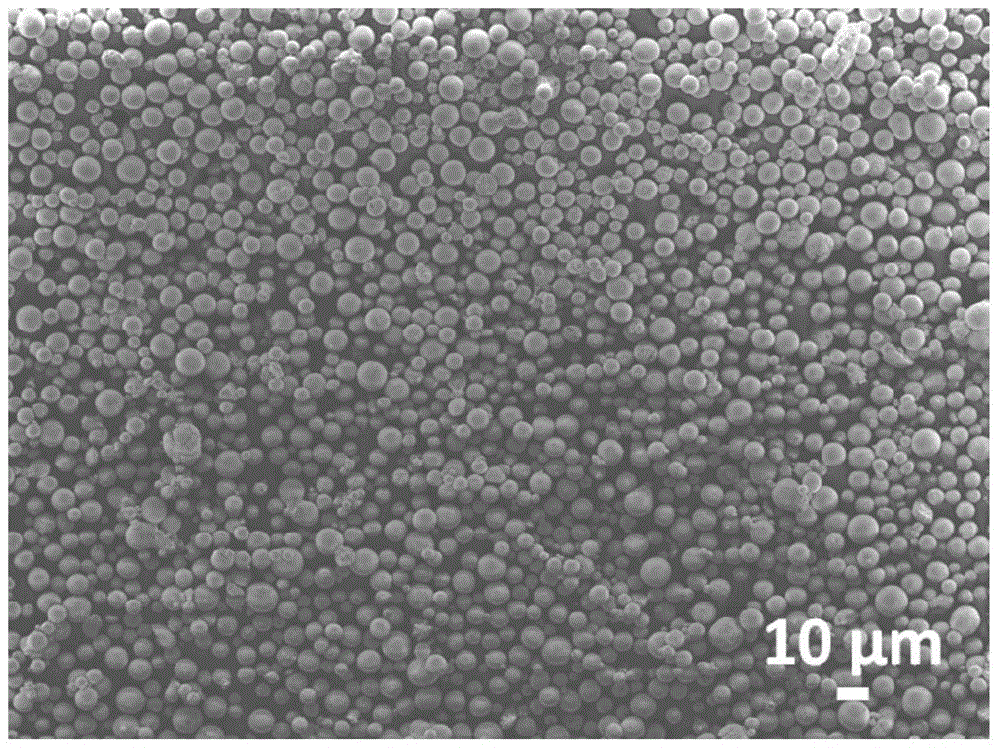

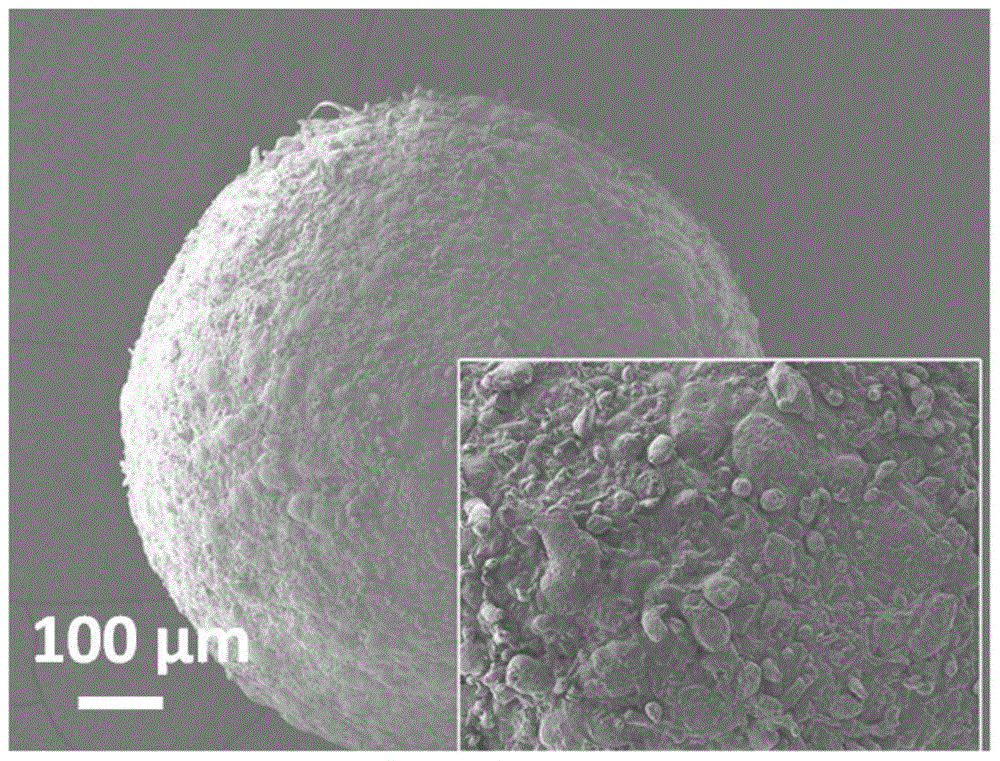

Image

Examples

Embodiment 1

[0082] (1) Homopolymerization of propylene

[0083] In a 500ml dry autoclave, first add 50ml of dry n-hexane, then successively add 1ml of triethylaluminum with a concentration of 1.8mol / L, 20.0mg of the carrier-type Ziegler-Natta catalyst A prepared above, and then feed propylene gas, at 60°C, under 0.2MPa pressure for 15 minutes, to obtain polypropylene particles, and directly proceed to the next step of reaction.

[0084] (2) Ethylene / propylene / diene copolymerization

[0085] Vent the propylene gas in the above step (1), then add 3ml of 1,9-decadiene monomer, and then feed the ethylene / propylene mixed gas with a gas molar ratio of 1:1, and the pressure in the polymerization system is 0.2 MPa, the copolymerization is carried out in a hexane solvent system, the polymerization temperature is controlled at 60° C., and the copolymerization reaction takes 45 minutes. After the polymerization was completed, the gas pressure in the autoclave was released, and the polymer was coll...

Embodiment 2

[0088] (1) Homopolymerization of propylene

[0089] In a 500ml dry autoclave, first add 100ml of dry n-hexane, then successively add 1ml of triethylaluminum with a concentration of 1.8mol / L, 20.0mg of the carrier-type Ziegler-Natta catalyst A prepared above, and then feed propylene gas, at 60°C, under 0.2MPa pressure for 15 minutes, to obtain polypropylene particles, and directly proceed to the next step of reaction.

[0090] (2) Ethylene / propylene / diene copolymerization

[0091] Vent the propylene gas in the above step (1), then add 3ml of 1,9-decadiene monomer, and then feed the ethylene / propylene mixed gas with a gas molar ratio of 1:1, and the pressure in the polymerization system is 0.5 MPa, the copolymerization is carried out in a hexane solvent system, the polymerization temperature is controlled at 60° C., and the copolymerization reaction takes 45 minutes. After the polymerization was completed, the gas pressure in the autoclave was released, the polymer was collect...

Embodiment 3

[0094] (1) Homopolymerization of propylene

[0095] In a 500ml dry autoclave, first add 100ml of dry n-hexane, then add 1ml of triethylaluminum with a concentration of 1.8mol / L, 20.0mg of the carrier-type Ziegler-Natta catalyst B prepared above, and then feed propylene Gas, polymerize at 60°C and 0.2MPa for 10 minutes to obtain polypropylene particles, and proceed to the next step of reaction directly.

[0096] (2) Ethylene / propylene / diene copolymerization

[0097] Vent the propylene gas in the above step (1), then add 8ml of 1,9-decadiene monomer, and then feed the ethylene / propylene mixed gas with a gas molar ratio of 1:2, and the pressure in the polymerization system is 0.5 MPa, the copolymerization is carried out in a hexane solvent system, the polymerization temperature is controlled at 60° C., and the copolymerization reaction takes 45 minutes. After the polymerization was completed, the gas pressure in the autoclave was released, and the polymer was collected and wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com