Phenolic resin, its composition, preparation method and application

A technology of phenolic resin and phenol, which is applied in the field of rubber composition containing the phenolic resin, phenolic resin and its preparation, and can solve problems such as complicated operation and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

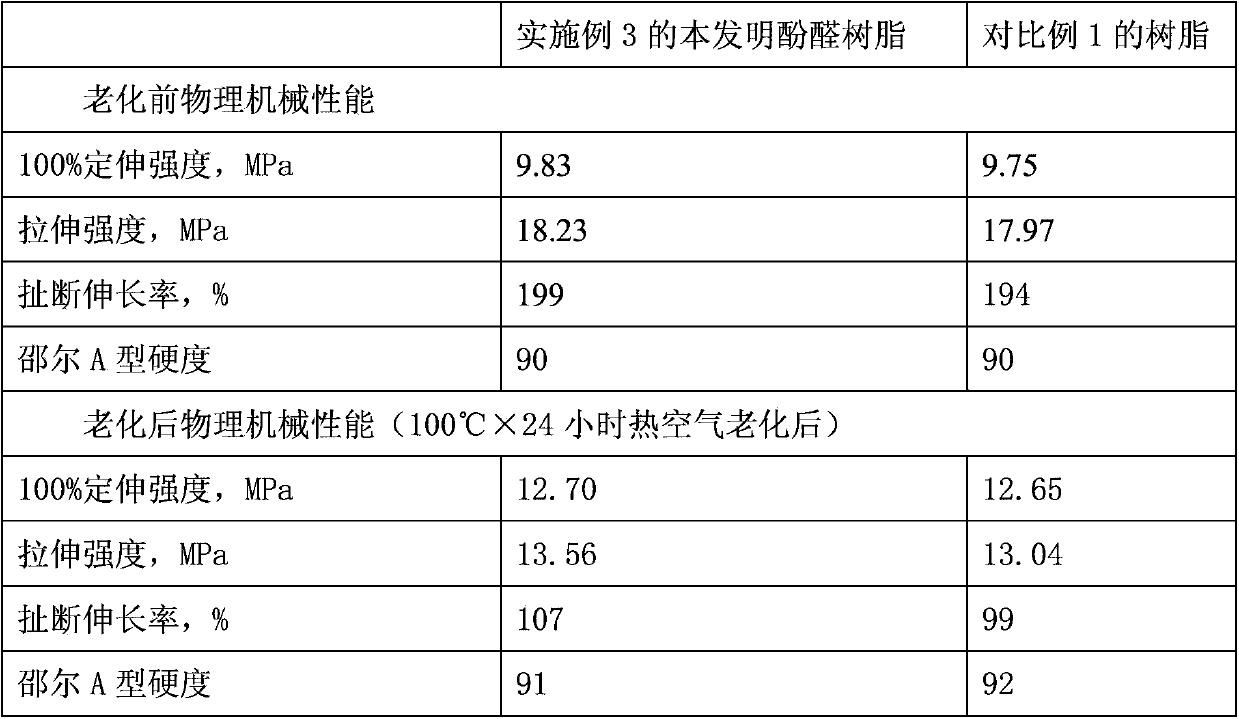

Examples

Embodiment 1

[0024] Add 188 g of phenol and 0.8 g of p-toluenesulfonic acid monohydrate into a 500 ml four-neck round bottom flask equipped with mechanical stirring, thermometer, reflux condenser and dropping funnel, heat to 100 °C under stirring, within 1 hour 97.4 g of 37% formaldehyde aqueous solution was added dropwise, and then refluxed for 1 hour. Then heated and distilled at atmospheric pressure to 160°C, slowly started vacuum distillation under reduced pressure, and distilled under reduced pressure at 2000 Pa vacuum degree and temperature 172°C for 1 hour to obtain the target product phenolic resin, namely reinforcing resin 1. After identification, the phenolic resin The softening point is 109°C, and the free phenol content is 0.15%. Produce 120 milliliters of waste water containing phenol. In this embodiment, atmospheric distillation can be carried out at 160-200°C. Vacuum vacuum distillation can be carried out at a vacuum degree of 5000-2000 Pa and a temperature of 168-172°C. ...

Embodiment 2

[0026] Add 188 g of phenol and 1.88 g of oxalic acid dihydrate to a 500 ml four-necked round-bottomed flask equipped with mechanical stirring, a thermometer, a reflux condenser and a dropping funnel, heat to 100°C under stirring, and drop in 20 minutes Complete 113.6 grams of 37% aqueous formaldehyde solution, then reflux for 1 hour. Then heated and distilled at atmospheric pressure to 160°C, slowly started vacuum distillation under reduced pressure, 1000 Pa vacuum and 195°C for 15 minutes to obtain reinforced resin 2 with a softening point of 99°C and a free phenol content of 0.34%. Produce 109 milliliters of waste water containing phenol. In this embodiment, atmospheric distillation can be carried out at 190-195°C. Vacuum vacuum distillation can be carried out at a vacuum degree of 5000-1000 Pa and a temperature of 190-195°C.

Embodiment 3

[0028] Add 188 grams of phenol and 1.88 grams of oxalic acid dihydrate to a 500-milliliter four-necked round-bottomed flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel, heat to 100°C under stirring, and add dropwise 65.3 grams of 37% Aqueous formaldehyde solution, then gradually added 18.7 g of paraformaldehyde, and then refluxed for 1 hour. Then heated and distilled at atmospheric pressure to 160°C, slowly started vacuum distillation under reduced pressure of 700 Pa and 178°C for 30 minutes to obtain reinforced resin 3 with a softening point of 101.4°C and a free phenol content of 0.52%. Produce 90 milliliters of waste water containing phenol. In this embodiment, the vacuum vacuum distillation can be carried out at a vacuum degree of 700 Pa and a temperature of 178-182°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com