Preparation method for glucan bioseparation and purification medium

A technology for biological separation and glucan, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of difficulty in obtaining high porosity data, complex reaction process and high preparation cost, To increase the static adsorption capacity, the preparation process is simple and stable, and the uniformity is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

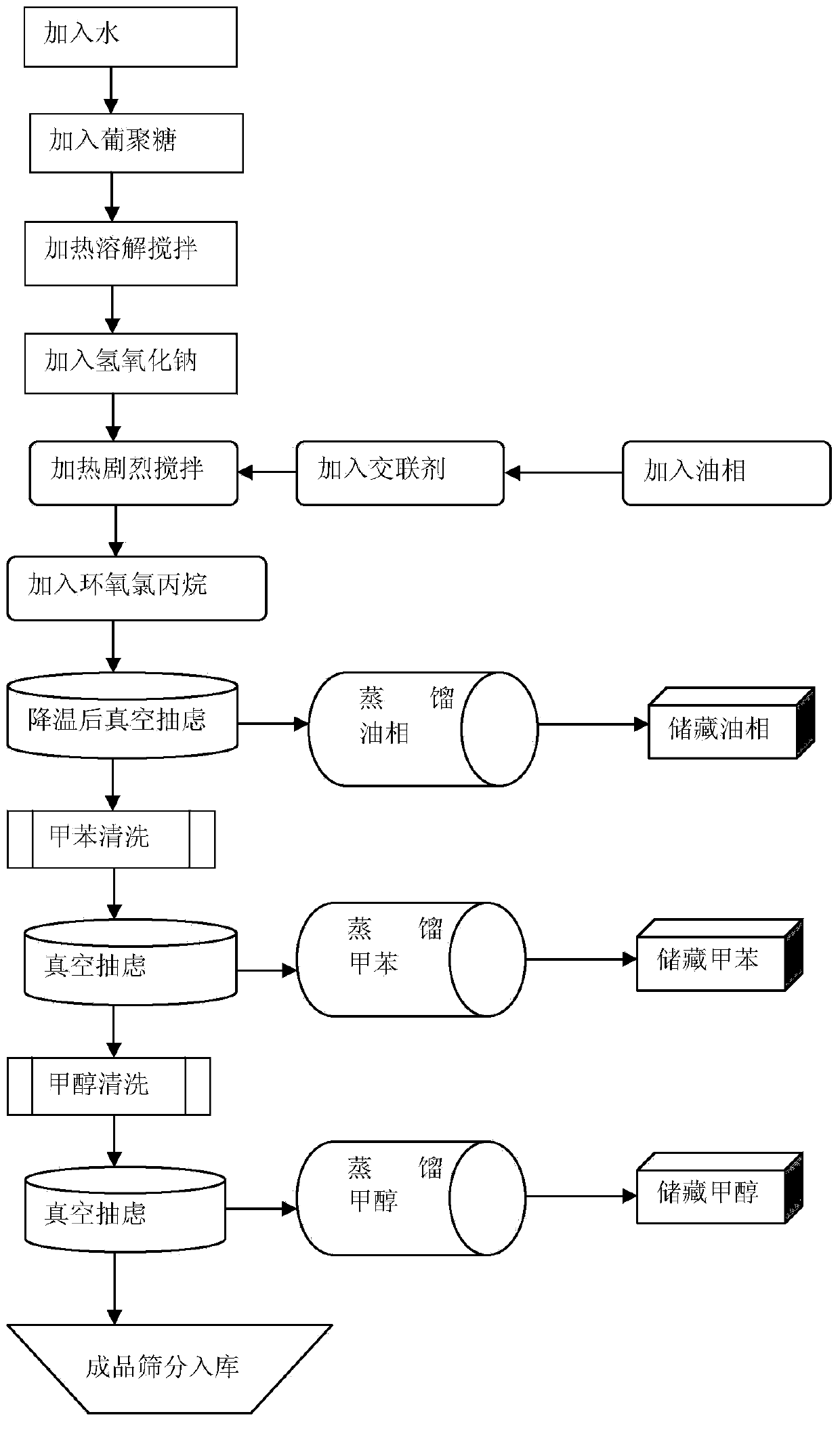

Method used

Image

Examples

Embodiment 1

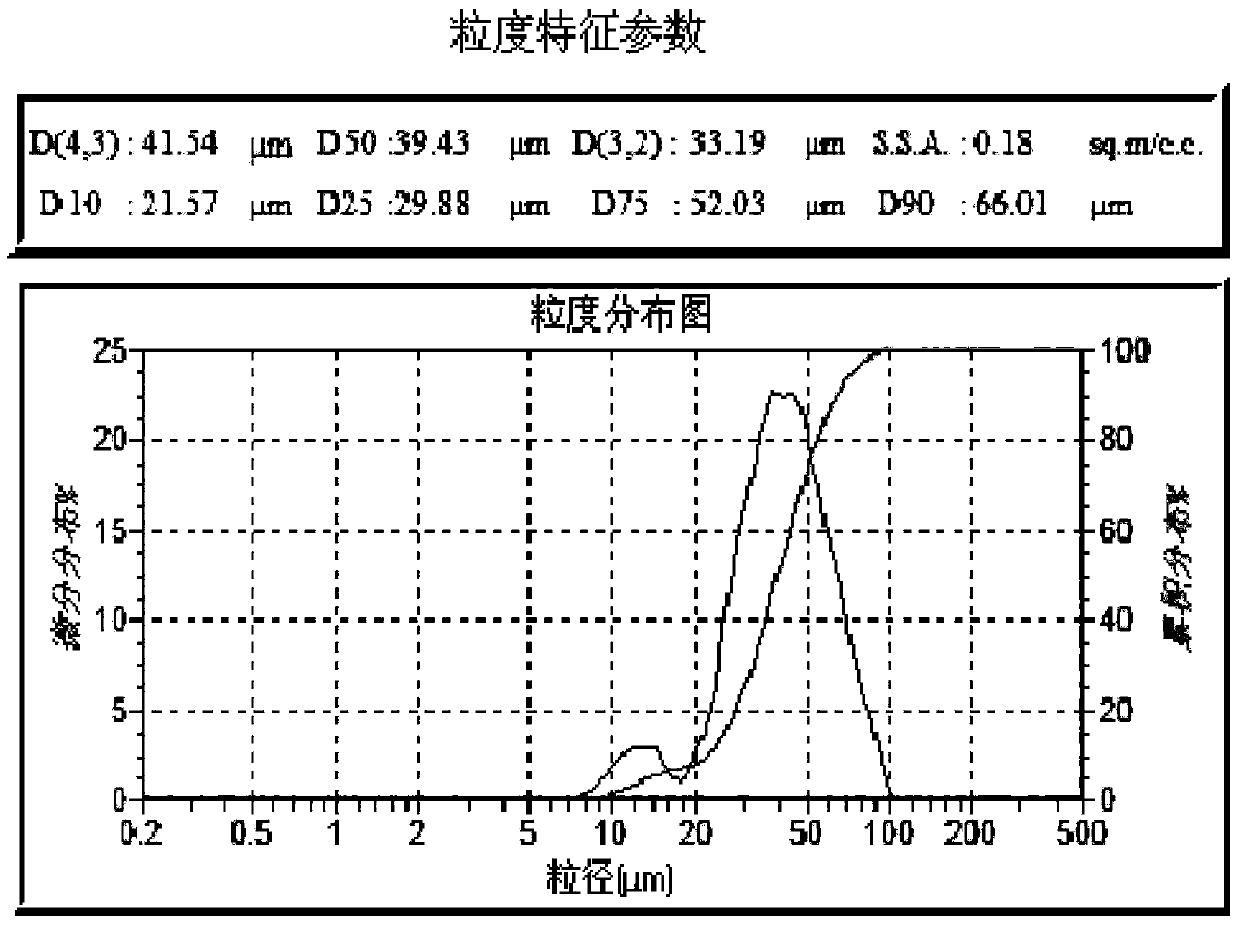

[0037] Weigh 3000g of dextran into 4000g of deionized water, heat to 50°C, stir and dissolve at 400rpm for 20h, add 250g of 50% NaOH solution, stir at 500rpm for 1h; weigh 70g of cellulose acetate into 6000g of dichloroethylene in alkanes, heated to 50°C, stirred and dissolved at 500rpm for 20h, quickly added the dextran solution into dichloroethane, weighed 600g of epichlorohydrin solution, slowly added dropwise to dichloroethane for 3h, and heated to 50 ℃, stirred vigorously at 900rpm for 3 hours, took samples and put them into ice water at 4℃ to solidify and form, and tested the particle size, appearance roundness and pore size of the dextran medium under a particle size analyzer and a digital microscope, respectively. Stop heating, reduce the rotation speed to 200rpm, use 4°C ice water on the outer wall of the oil phase reactor to quickly cool down to below 23°C, transfer the dextran medium to a microporous glass funnel, filter with a vacuum pump, and clean 10-20 liters res...

Embodiment 2

[0040] Weigh 1500g of dextran and add it to 3000g of deionized water, heat to 50°C, stir and dissolve at 400rpm for 20h, add 250g of 50% NaOH solution, and stir at 500rpm for 1h; weigh 70g of cellulose acetate and add it to 3500g of dichloroethylene In alkanes, heated to 50°C, stirred and dissolved at 500rpm for 20h, quickly added the dextran solution into dichloroethane, weighed 350g of epichlorohydrin solution, slowly added dropwise to dichloroethane for 3h, and heated to 50 ℃, stirred vigorously at 900rpm for 3 hours, took samples and put them into ice water at 4℃ to solidify and form, and tested the particle size, appearance roundness and pore size of the dextran medium under a particle size analyzer and a digital microscope, respectively. Stop heating, reduce the rotation speed to 200rpm, use 4°C ice water on the outer wall of the oil phase reactor to quickly cool down to below 23°C, transfer the dextran medium to a microporous glass funnel, filter with a vacuum pump, and ...

Embodiment 3

[0043] Weigh 100g of dextran and add it to 200g of water, heat to 50°C, stir and dissolve at 400rpm for 20h, add 250g of 50% NaOH solution, and stir at 500rpm for 1h; weigh 70g of cellulose acetate and add it to 1000g of dichloroethane , heated to 50°C, stirred and dissolved at 500rpm for 20h, quickly added the dextran solution into dichloroethane, weighed 100g of epichlorohydrin solution and slowly added dropwise to dichloroethane for 3h, heated to 50°C, Stir vigorously at 900rpm for 3 hours, take samples and put them into ice water at 4°C to solidify and form, and measure the particle size, appearance roundness and pore size of the dextran medium under a particle size analyzer and a digital microscope, respectively. Stop heating, reduce the rotation speed to 200rpm, use 4°C ice water on the outer wall of the oil phase reactor to quickly cool down to below 23°C, transfer the dextran medium to a microporous glass funnel, filter with a vacuum pump, and clean 10-20 liters respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com