Preparation method for electroactive polypyrrole film

A polypyrrole film and pyrrole film technology, which is applied in the electrolytic process, electrolytic components, electrolytic organic production, etc., can solve the problems of reducing electroactivity, polymer peroxidation, increasing response voltage, etc., achieving easy control and few influencing factors. , good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

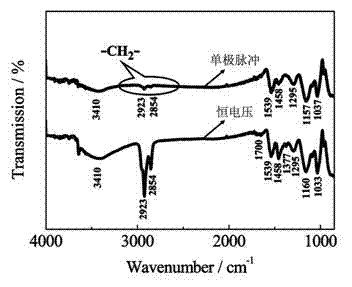

[0031] Implement a kind of preparation method of electroactive polypyrrole membrane, specifically comprise electrochemical unipolar pulse method, and its described preparation method is carried out by following steps:

[0032] Step 1, dissolving a certain amount of pyrrole monomer in water to form an aqueous phase solution A with a pyrrole concentration of 0.06-0.6 mol / L;

[0033] Step 2, dissolving a certain amount of electrolyte in water to form an aqueous solution B with an electrolyte concentration of 1.2 to 3 mol / L, wherein the electrolyte is one of potassium chloride, potassium sulfate, potassium nitrate and potassium perchlorate, wherein The performance of the polypyrrole membrane prepared with potassium chloride as the electrolyte solution is the best;

[0034] Step 3, a certain quality of inorganic acid solution is dissolved in water to form a hydrogen ion concentration of 0.3 ~ 3 mol / L aqueous solution C, its inorganic acid is a kind of hydrochloric acid, sulfuric ac...

Embodiment 1

[0043] (1) 2.0538 g pyrrole monomer is dissolved in the aqueous solution of 100 ml and is mixed with the pyrrole aqueous solution A of 0.3 mol / L;

[0044] (2) Dissolve 8.9849 g potassium chloride in the aqueous solution of 100 ml and be mixed with the potassium chloride aqueous solution B of 1.2 mol / L;

[0045] (3) 2.9200 g concentrated hydrochloric acid is dissolved in the aqueous solution of 100 ml and is mixed with the hydrochloric acid solution C of 0.3 mol / L;

[0046] (4) Put 10 ml of solution A, solution B and solution C into the reaction vessel and stir evenly;

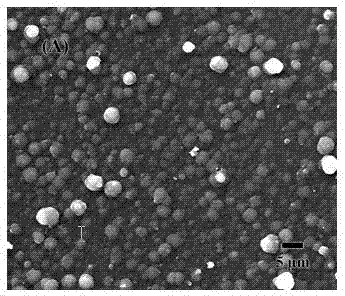

[0047] (5) Using a three-electrode system (the working electrode has an effective area of 0.5 cm 2 Platinum sheet, the counter electrode is a platinum sheet, and the reference electrode is a saturated calomel electrode), the temperature of the reactor is controlled at 10 °C, and the single-stage pulse signals are set as follows: the pulse potential is 0.7 V, the pulse on-off time ratio is 10 ms / 100 ms; th...

Embodiment 2

[0051] (1) 1.0269 g pyrrole monomer is dissolved in the aqueous solution of 100 ml and is mixed with the pyrrole aqueous solution A of 0.15 mol / L;

[0052] (2) 11.2311 g potassium chloride is dissolved in the aqueous solution of 100 ml and is mixed with potassium chloride aqueous solution B of 1.5 mol / L;

[0053] (3) 2.92 g concentrated hydrochloric acid is dissolved in the aqueous solution of 100 ml and is mixed with the hydrochloric acid solution C of 0.3 mol / L;

[0054] (4) Put 10 ml of solution A, solution B and solution C into the reaction vessel and stir evenly;

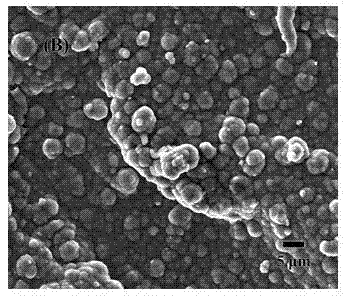

[0055] (5) Using a three-electrode system (the working electrode has an effective area of 1 cm 2 carbon paper, the counter electrode is gold, the reference electrode is a saturated calomel electrode), the temperature of the reactor is controlled at 5 ℃, and the single-stage pulse signals are set as follows: the pulse potential is 0.7 V, and the pulse on-off time ratio is 20 ms / 200 ms; the number of pulses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com