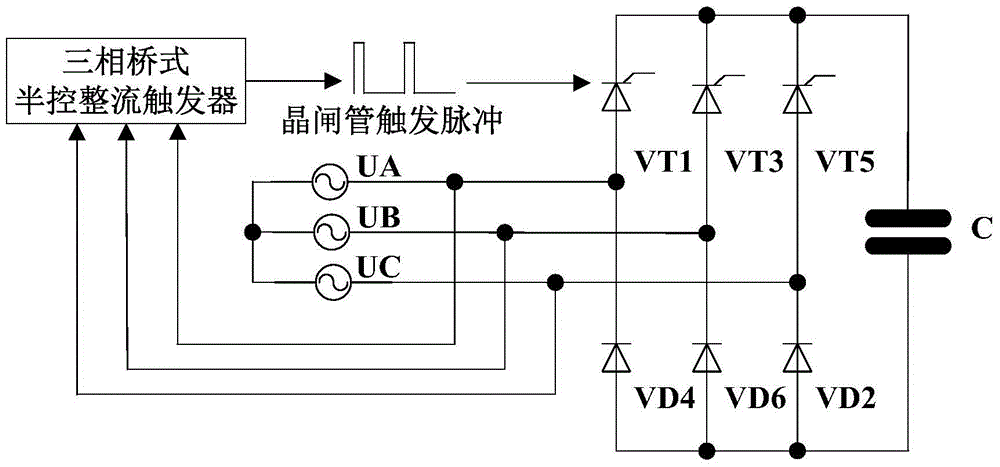

Three-phase bridge-type half-control rectification trigger circuit with protection function

A three-phase bridge type, semi-controlled rectification technology, applied in emergency protection circuit devices, output power conversion devices, AC power input conversion to DC power output, etc., can solve large starting current, contact oxidation, poor contact, etc. problem, to achieve the effect of ensuring safe and reliable work, flexible control mode, and small starting current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

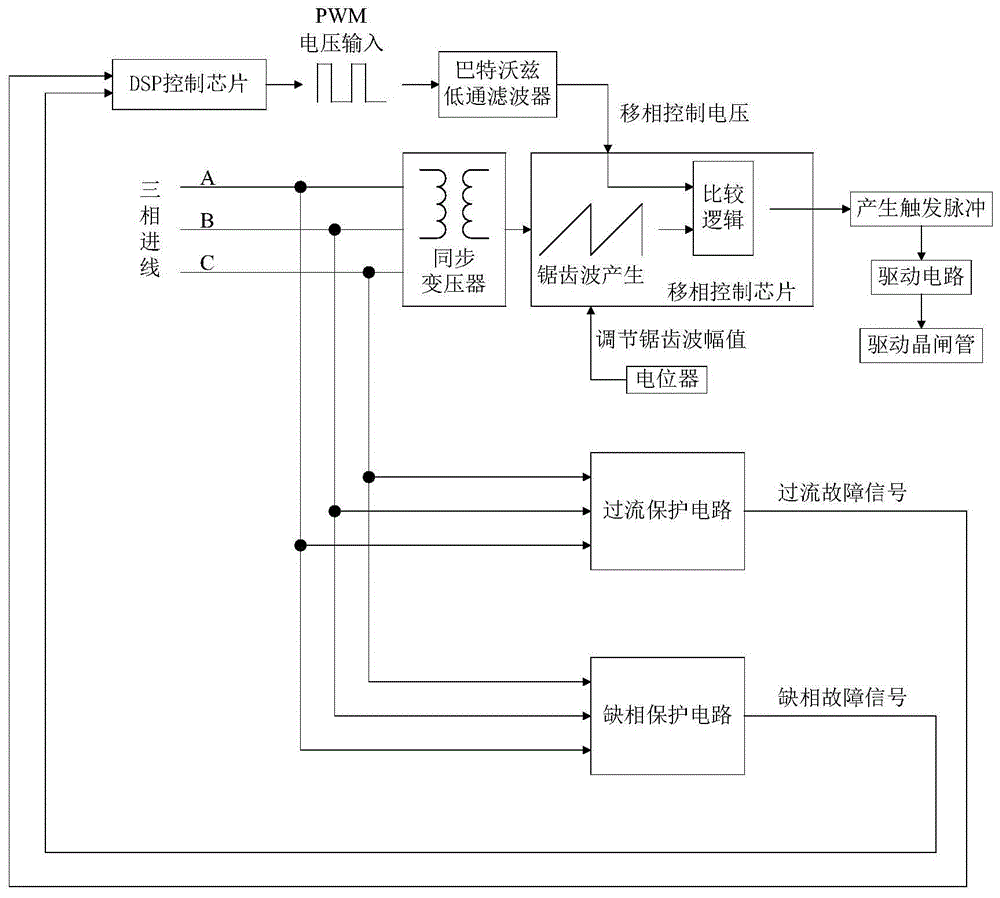

[0030] The present invention will be further explained below in conjunction with the accompanying drawings.

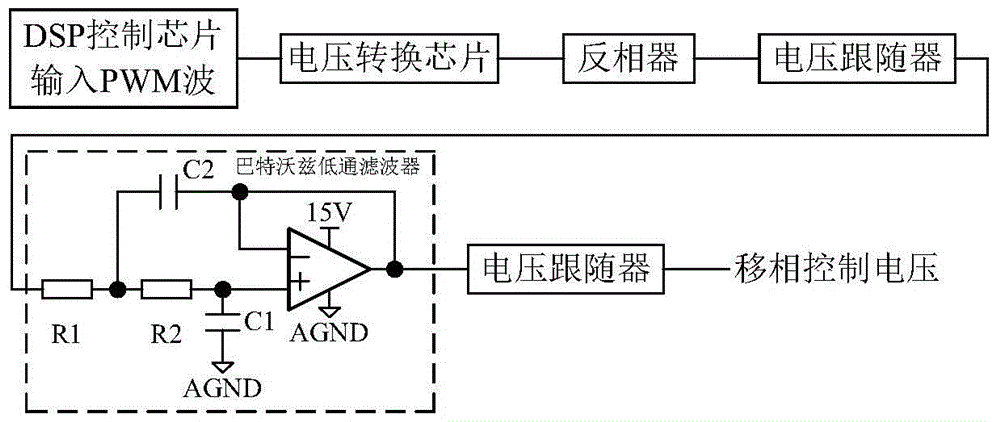

[0031] Such as figure 2 As shown, a three-phase bridge half-controlled rectification trigger circuit with protection function includes a phase-shift control voltage generation circuit, a phase-shift trigger pulse generation circuit and a drive circuit. Such as image 3 As shown, the phase-shift control voltage generating circuit includes a DSP control chip, a voltage conversion chip, an inverter, a voltage follower and a Butterworth low-pass filter. The DSP control chip outputs a PWM voltage with a duty ratio of 10% to 90%. After the PWM voltage is linearly converted by the voltage conversion chip, it is converted into a PWM voltage with an average value of 1.5V to 13.5V and then input to the inverter for voltage inversion. Phase, to get a PWM voltage with an average value of 13.5V to 1.5V; the inverted PWM voltage is input to the Butterworth low-pass filter through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com