Preparation method of lubricating film

A technology of lubricating thin film and thin film layer is applied in the field of preparation of lubricating thin film, which can solve the problems of high cost, high production cost, and the resolution cannot be well solved, and achieves the effect of satisfying pattern transfer, high resolution and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

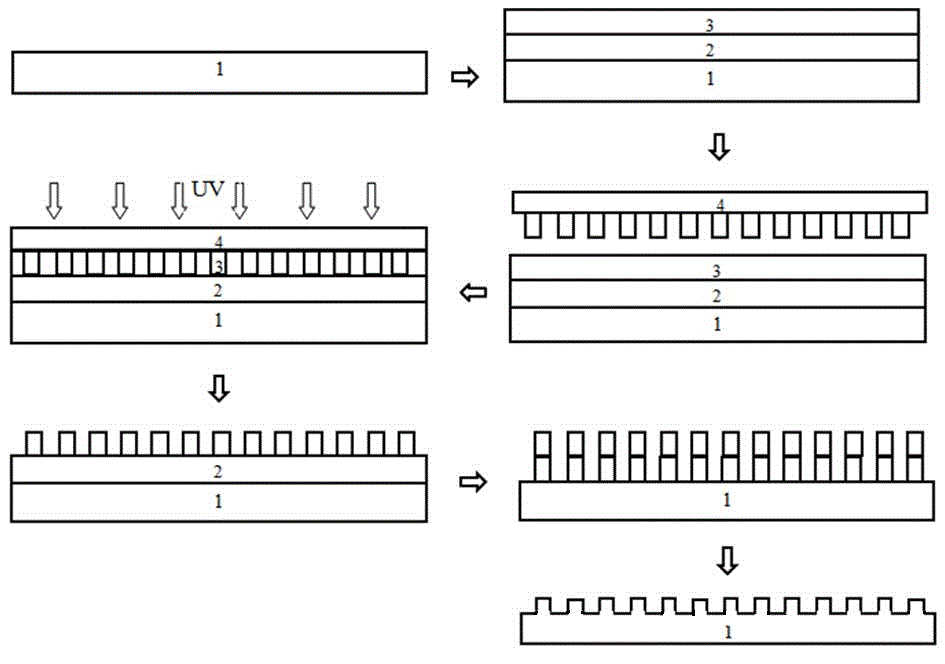

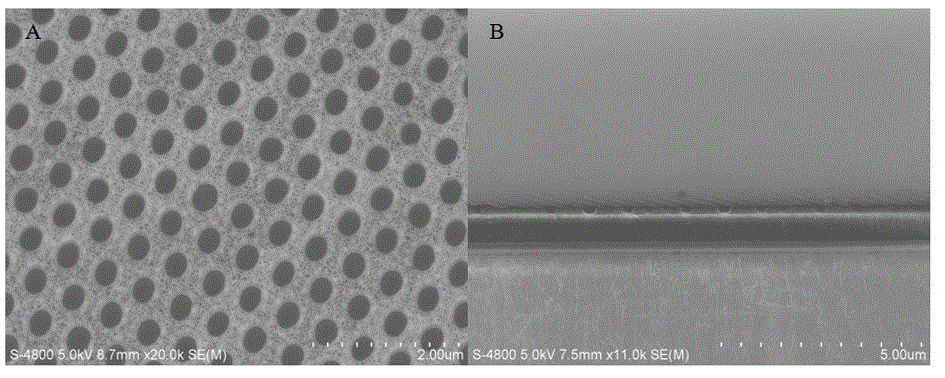

[0044] Embodiment 1: A preparation method of a lubricating film, using ultraviolet hardening imprint lithography (UV-NIL), depositing a silicon-doped diamond-like film on a silicon substrate to prepare a nanometer pattern.

[0045] See attached figure 1 First, the surface of the film layer 1 is treated, and the dust and foreign matter on the surface are blown off with high-purity nitrogen gas for about 1 minute; then the SU-8 photoresist is spin-coated on the surface of the film layer with a thickness of about 500nm, and the spin The sample coated with SU-8 photoresist was exposed under a 1000W ultraviolet lamp for 1 minute, and then the exposed sample was cured by heating at 110°C for 5 minutes to form an intermediate layer 2; then, the cured sample was spin-coated with UV curable adhesive, The thickness is 200nm to form a UV-curable nano-imprint adhesive layer 3; then cover the entire sample with a soft imprint film 4 with a structure, and expose the fully covered sample to ...

Embodiment 2

[0048] Embodiment 2: A method for preparing a lubricating film, using ultraviolet hardening imprint lithography (UV-NIL), depositing a silicon-doped diamond-like film on the surface of a warped sapphire substrate to prepare a nano-pattern.

[0049] First, the surface of the curved substrate is treated, and the dust and foreign matter on the surface are blown off with high-purity nitrogen for about 1 minute; then the SU-8 photoresist is spin-coated on the surface of the film layer with a thickness of about 400nm, and the spin-coating The sample of SU-8 photoresist was exposed under a 1000W ultraviolet lamp for 1 minute, and then the exposed sample was cured by heating at 110°C for 5 minutes to form an intermediate layer; then, the cured sample was spin-coated with UV curable adhesive, with a thickness of 150nm to form a UV-curable nano-imprint adhesive layer; then cover the entire sample with a soft imprint film plate with a structure, and expose the fully covered sample to a 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com