Vapor-liquid separator input and output structure and manufacturing process thereof

A vapor-liquid separator, input and output technology, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of cumbersome and easily damaged manufacturing processes, reduce manufacturing costs, reduce welding processes, and reduce quality hidden dangers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

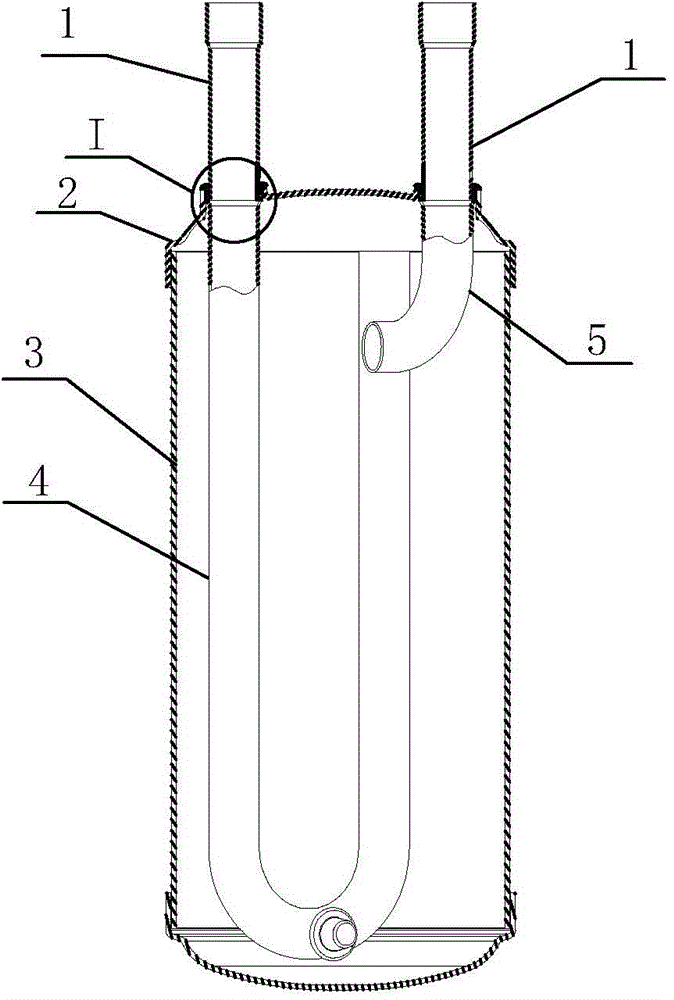

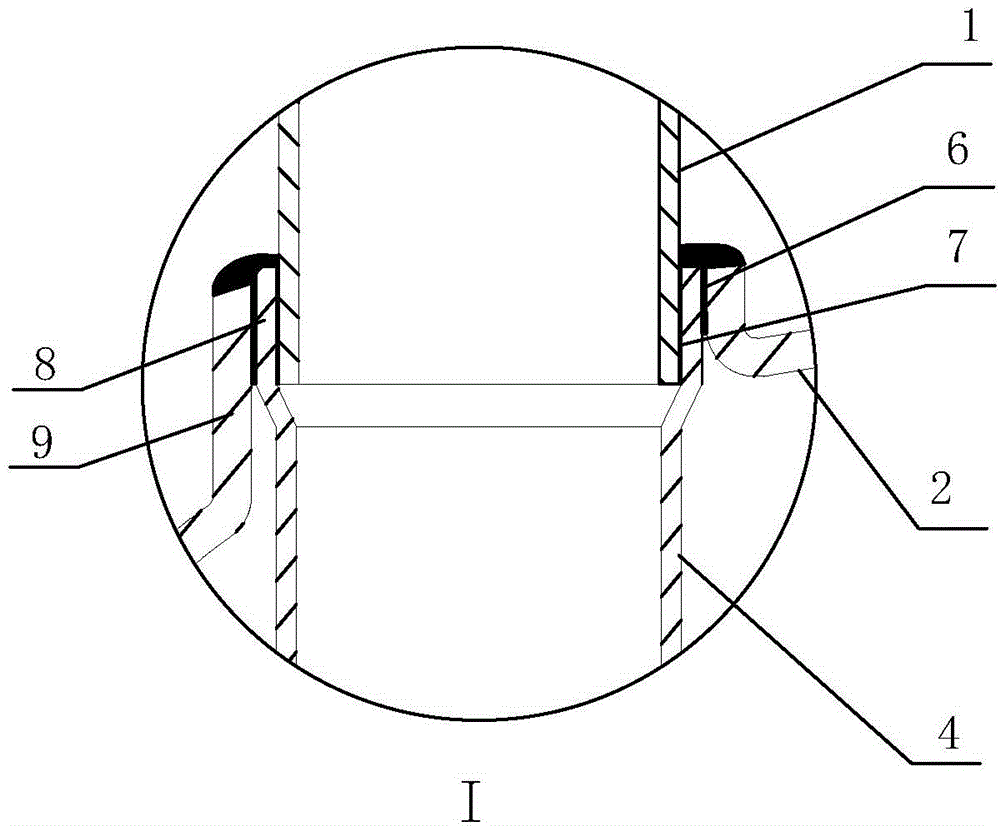

[0015] Such as figure 1 and figure 2 As shown, the input and output structure of the gas-liquid separator of the present invention includes a tank body 3, an upper end cover 2, a stainless steel input pipe 5 and a stainless steel output pipe 4, the upper end cover 2 is sealed at the end of the tank body 3, and the upper end cover 2 is provided with Inlet and outlet, the inlet and outlet on the upper end cover 2 are provided with a flanging part 9, the flanging part 9 is an outer flanging, the stainless steel input pipe 5 and the stainless steel output pipe 4 pass through the inlet and the outlet respectively, and the stainless steel The outer ends of the input pipe 5 and the stainless steel output pipe 4 are provided with flared portions 8, and each flared portion 8 is inserted with a copper connecting pipe 1, and the bottom end surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com