Silicon carbide ceramic lined desulphurization pump

A technology for lining silicon carbide and desulfurization pumps, which is applied to pumps for special fluids, components of pumping devices for elastic fluids, pumps, etc., which can solve the problem of reduced sealing performance at plane joints, short service life, and increased difficulty. and other problems to achieve the effect of ensuring shape and dimensional accuracy, prolonging service life and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

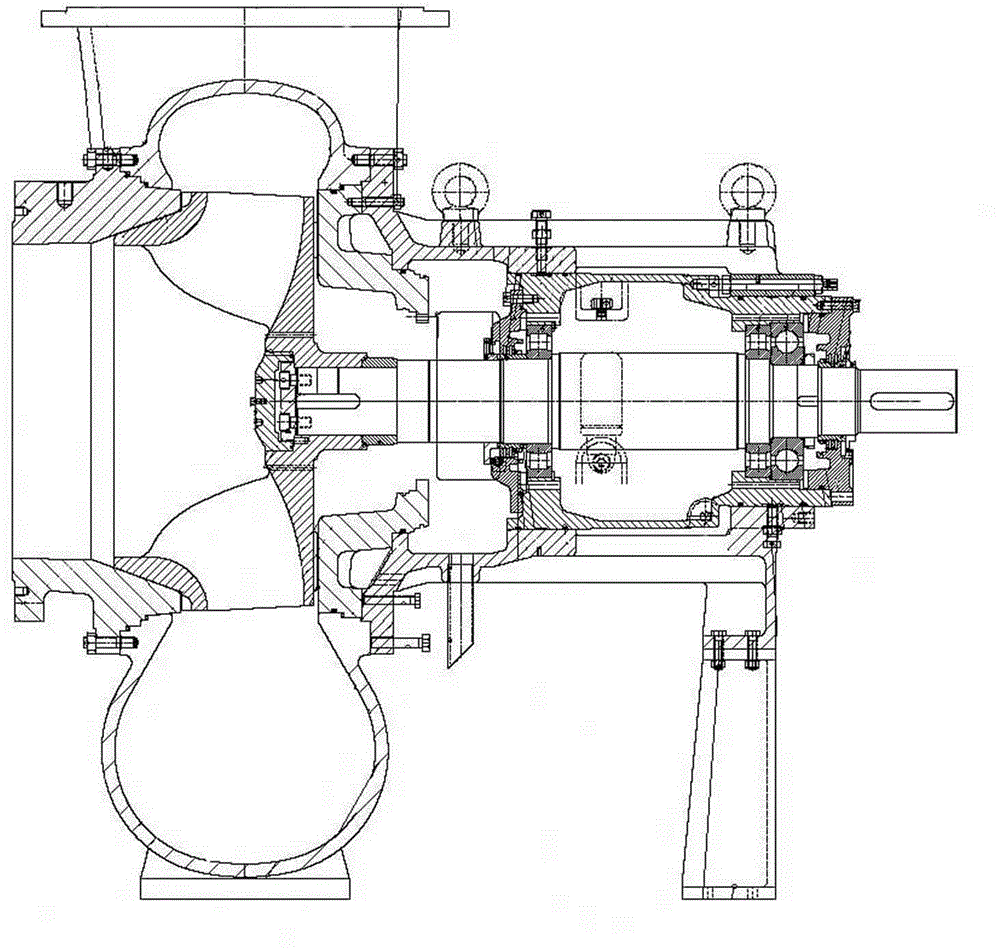

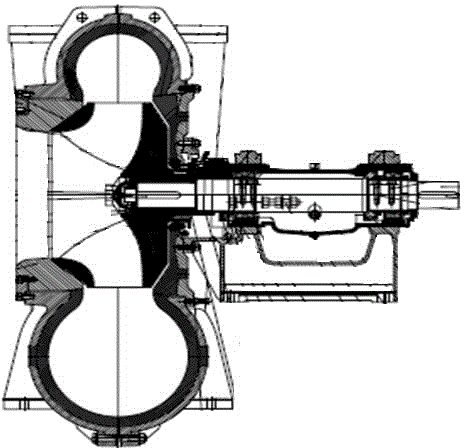

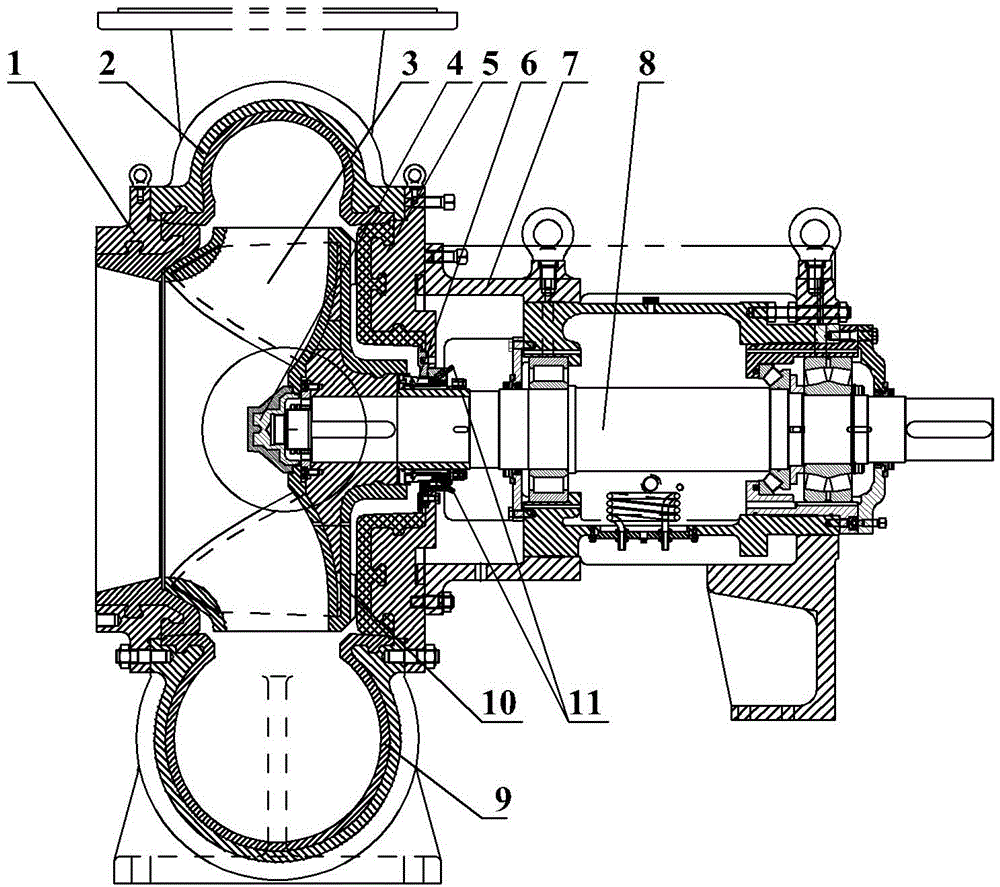

[0086] Example: The specific manufacturing process of the ceramic desulfurization pump (ACP-TL700-22).

[0087] (1) Determine the suction diameter and discharge diameter: suction diameter = 800mm, discharge diameter = 700mm, determine the rotational speed as 595r / min, and the specific rotational speed of the pump = 330.4. Determine the structural form as a single-stage, single-suction volute structural form.

[0088] (2) Determine the geometric size of the impeller according to the performance and parameters: inlet diameter D 0 =Φ690, outlet width b 2 =220, outer diameter D2=Φ865, blade wrap angle ψ=115°. The number of blades is 5, and the hydraulic diagram and processing diagram of the impeller are drawn according to the calculation parameters.

[0089] (3) Determine the design of the spiral vortex chamber: base circle diameter D 3 =Φ918, vortex chamber inlet width b 3 =320.

[0090] Determination of the area of the end face of the vortex chamber: the size of the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com