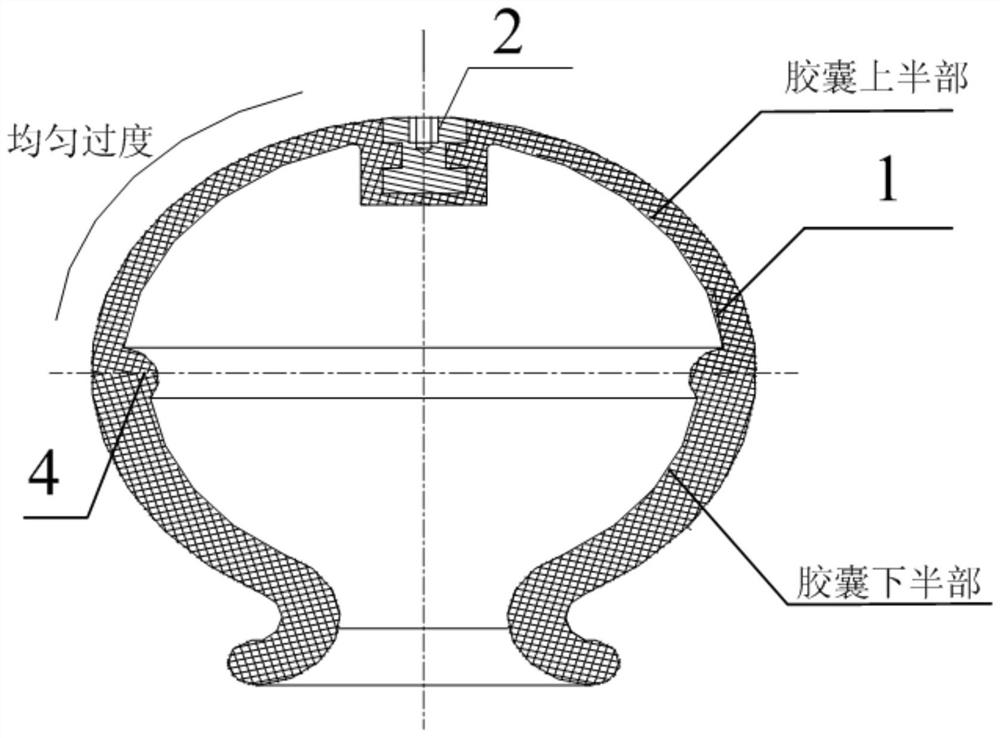

Capsule assembly for spherical pressure accumulator of servo mechanism, molding die and molding method thereof

A technology of servo mechanism and molding method, which is applied in the direction of household appliances, household components, and other household appliances, and can solve the problems of unfavorable space launch and weapon system miniaturization and light weight design, large volume of piston accumulator, pressure holding pressure, etc. Low-level problems, to achieve the effect of prolonging the service life of dynamic flexion, light weight, and long holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] 100 parts of chlorohydrin raw rubber, 1.5 parts of stearic acid, 45 parts of carbon black N539, 3 parts of lead tetroxide, 2 parts of accelerator NA-22, 1.5 parts of antioxidant NBC, 3 parts of antioxidant 4010NA, uniform mixing After parking for 1-2 days, vulcanize and test.

[0078] Performance test results:

[0079] Shore A 78 hardness; tensile strength 17MPa; elongation at break 260%; permanent set at break 4.0%; permanent set at compression (100℃×48h, compression 30%) 7.6%.

Embodiment 2

[0081] 90 parts of chlorohydrin raw rubber, 10 parts of nitrile rubber, 1.5 parts of stearic acid, 45 parts of carbon black N539, 3 parts of lead tetroxide, 1.5 parts of accelerator NA-22, 1.5 parts of antioxidant NBC, and antioxidant 4010NA 3 parts, DCP 0.5 parts, anti-aging agent 4010NA 3 parts, after mixing evenly, park for 1 to 2 days, vulcanize and test.

[0082] Performance test results:

[0083] Hardness shore A 80; tensile strength 20MPa; elongation at break 256%; permanent deformation at break 2.0%.

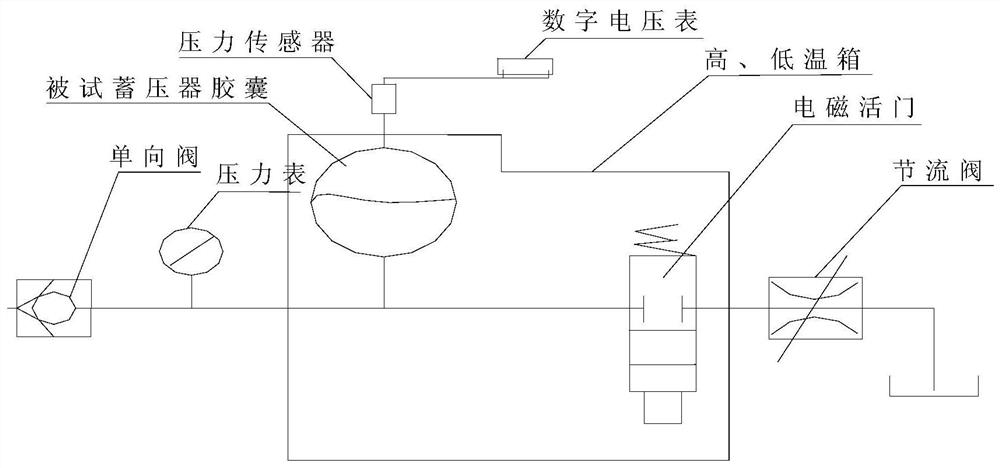

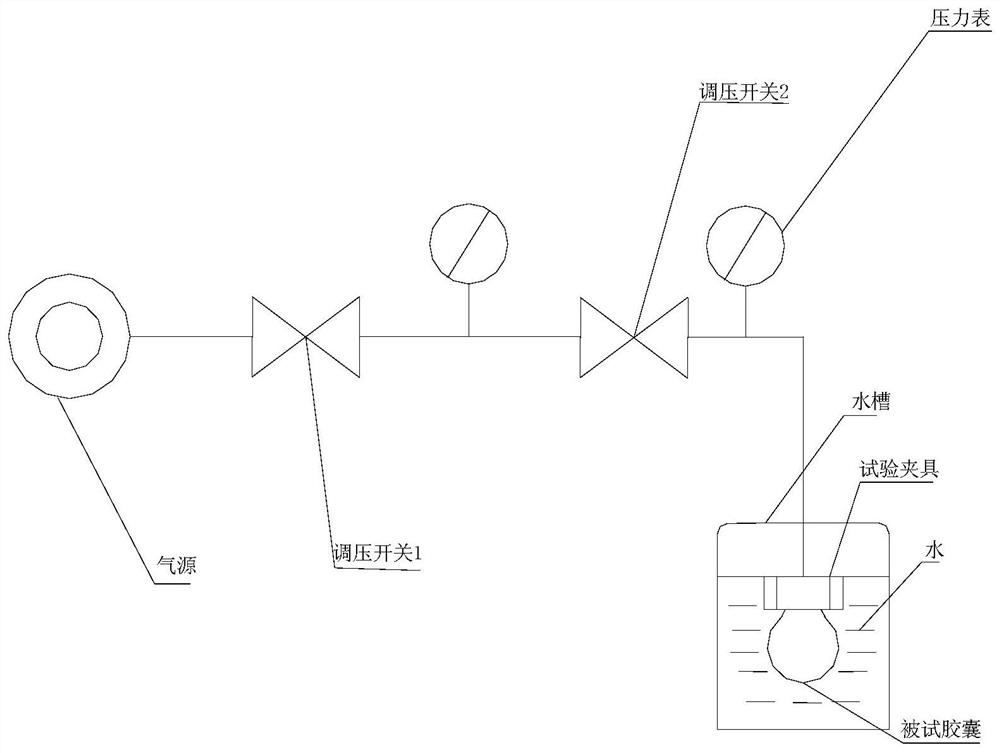

[0084] Using the above two typical rubber materials and using the two specifications of the spherical capsule mold of the present invention, the size of the epichlorohydrin rubber spherical capsule (inner diameter size: Ф95mm, Ф120mm) is injected and molded at one time. The product quality meets the design of aerospace vehicles and missile weapons. Technical requirements and functional requirements. The spherical capsule test piece is first subjected to inflation (0.1MPa) pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com