Micro-elastic woven fabric with imitating knitting effect and its weaving process

A technology of micro-elasticity machine and imitation knitting, which is applied in the direction of textiles, papermaking, fabrics, textiles, etc. It can solve the problem of single style and achieve the effect of good elasticity, changeable visual style, and reasonable and effective process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

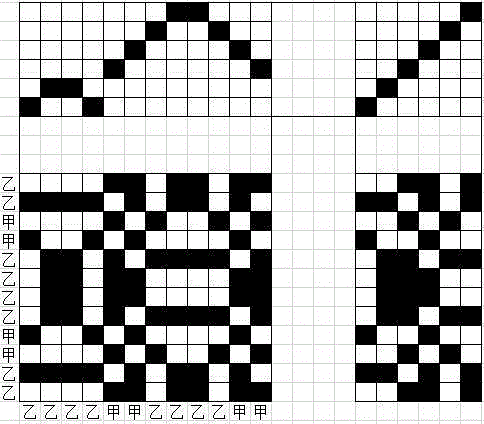

Image

Examples

Embodiment 1

[0013] A micro-elastic woven fabric with imitation knitting effect provided by this embodiment, the warp yarn is made of 75 D The outer wrapping specification of stretch textured yarn is 40 D The fine-denier high-shrinkage composite thread formed by spandex yarn is used as the material of the nail warp and the specification is 10 S / 1 cotton yarn with a gauge of 6 S Coarse-count low-shrinkage parallel-twisted composite yarn formed by combining and twisting cotton yarns of / 1 is formed by parallel arrangement of the B warp in the order of 4 B warps and 2 A warps; the weft yarn includes a specification of 75 D The outer wrapping specification of stretch textured yarn is 40 D The fine-denier high-shrinkage composite thread formed by spandex yarn is used as the material of Jiawei and the specification is 10 S / 1 cotton yarn with a gauge of 6 S Coarse-count low-shrinkage double-twist composite yarn formed by combining and twisting the cotton yarn of / 1 is the second weft of mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com