High-strength aluminum alloy used for lithium ion battery shell and having excellent laser welding performance

A lithium-ion battery, laser welding technology, applied in the direction of battery pack parts, circuits, electrical components, etc., can solve problems such as difficulty in meeting the performance requirements of new products, insufficient expansion resistance of battery shells, and easy deformation, and achieve excellent laser performance. Welding performance, beneficial to industrial production and application, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

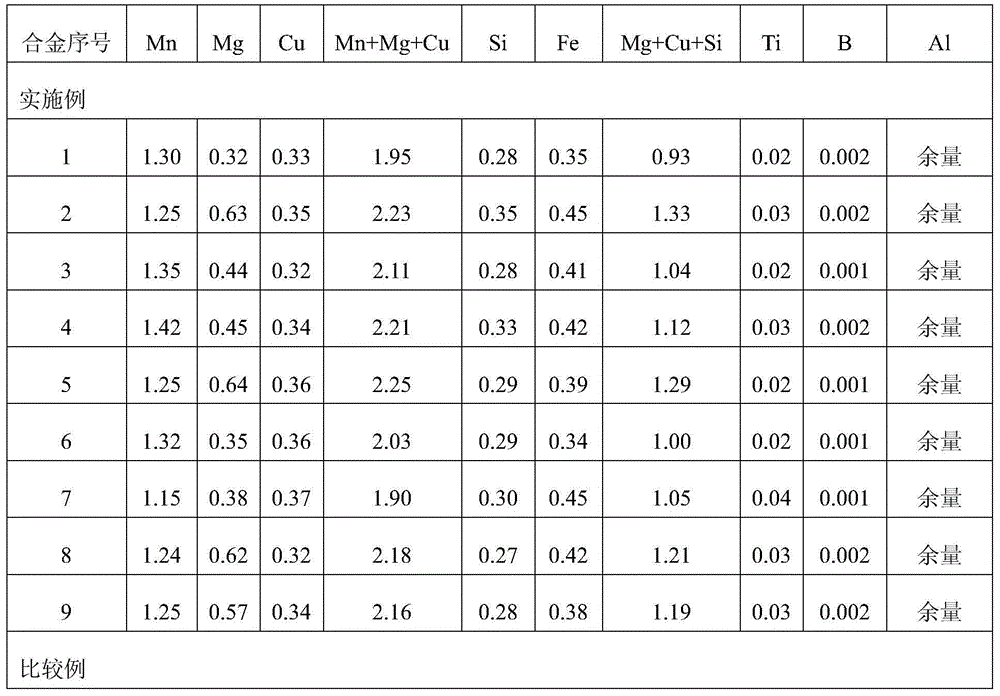

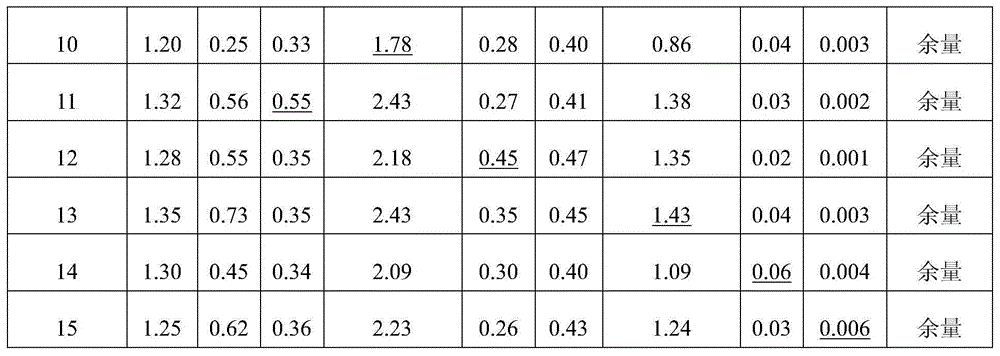

[0057] According to the composition of each alloy in Table 1, the semi-continuous casting method was used to prepare the ingot, the thickness of the ingot was 500mm, and the width was 1100mm.

[0058] After the face milling of the ingot, the homogenization treatment was carried out, the heating temperature was 600° C., and the holding time was 8 hours.

[0059] After the homogenization is completed, hot rolling is started, and the final rolling temperature is controlled at 280° C. to obtain a hot-rolled sheet with a thickness of 6 mm.

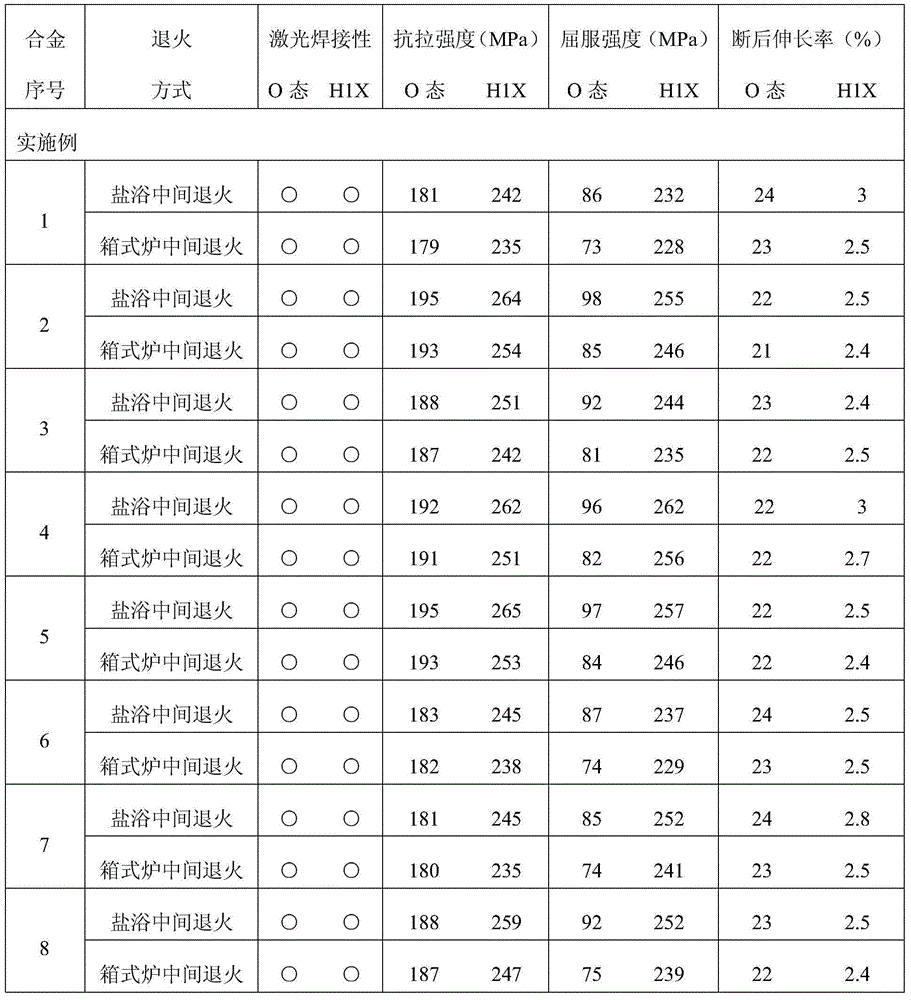

[0060] After the hot-rolled sheet is cooled to room temperature, it is cold-rolled. When preparing the O-state sheet, it is directly cold-rolled to the target thickness (1mm-2mm), and then the final annealing is performed to obtain the O-state sheet; when preparing the H1X-state sheet, it is cold-rolled first to obtain different thicknesses. The intermediate cold-rolled sheet, and then carry out intermediate annealing in two ways: ①salt bath in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com