Strategy for producing acetoin through efficient fermentation based on AR/BDH enzymatic properties of bacillus subtilis

A technology of Bacillus subtilis and acetoin, which is applied in the fields of genetic engineering and fermentation engineering, can solve problems such as related properties that cannot be further studied, and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Amplification of target gene and construction of recombinant Bacillus subtilis

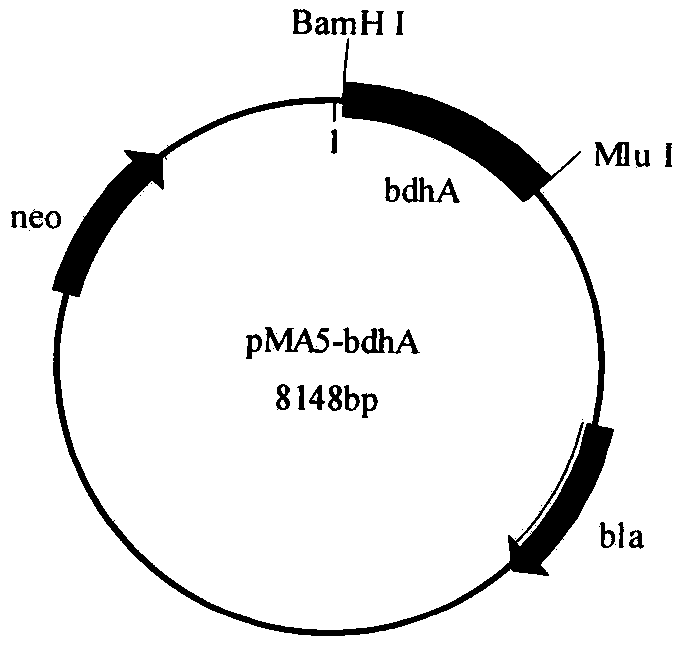

[0016] The schematic diagram of the construction of plasmid pMA5-bdhA is as follows: figure 1 As shown, the specific process is as follows:

[0017] First, using the chromosomal DNA of the bacterial strain B.subtilis JNA as a template, using primers P1 and P2, a 1041bp nucleotide sequence was amplified by PCR technology to obtain a bdhA gene as shown in SEQ ID NO: 1, and the purified After the bdhA gene was digested by restriction endonucleases MluI and BamHI, it was connected with the plasmid pMA5 digested by the above two restriction endonucleases to construct the recombinant plasmid pMA5-bdhA. 4 Under the action of DNA ligase, connect overnight at 16°C, transform the connection liquid into E. coli competent E.coli JM109, pick the positive transformant, extract the plasmid in the transformant, and confirm the recombinant plasmid pMA5-bdhA by enzyme digestion The build was ...

Embodiment 2

[0021] Example 2: Determination of activity of acetoin reductase of recombinant bacteria B. subtilis JNA / pMA5-bdhA

[0022] (1) Enzyme activity assay buffer system

[0023] Acetoin reductase: 0.05M acetoin, 50mM sodium phosphate buffer pH6.5, 5mM NAD + ;

[0024] 2,3-butanediol dehydrogenase: 0.1M 2,3-butanediol, 50mM sodium phosphate buffer pH8.0, 5mM NADH;

[0025] (2) Enzyme activity assay

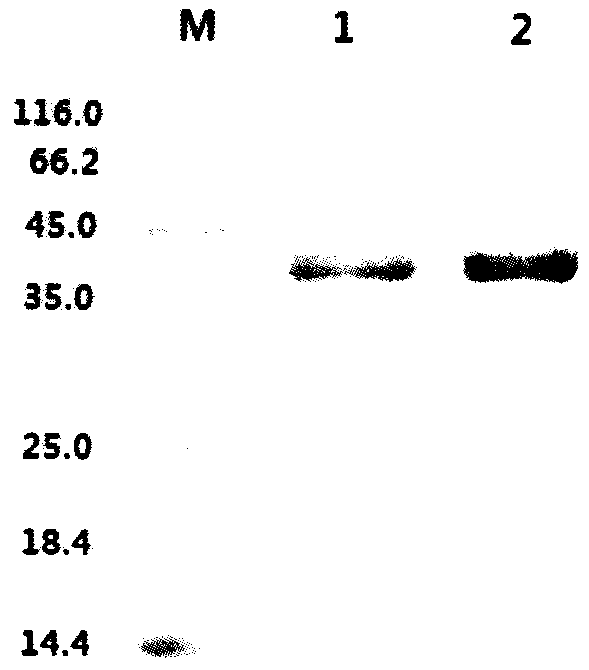

[0026] The recombinant bacteria B.subtilis JNA / pMA5-bdhA constructed in Example 1 and the starting strain B.subtilis JNA were inoculated in 10 mL of LB medium containing kanamycin, cultured with shaking at 37°C overnight, and the next day at 4% The inoculum amount was transferred to LB medium, cultured at 37°C for 24h, the fermentation broth was taken at 4°C, centrifuged at 10,000r / min for 10min, washed 3 times with sodium phosphate buffer solution of pH 7.0, suspended in Z buffer, and ultrasonically crushed. Prepare crude enzyme solution. Add 20 μl of crude enzyme solution to the ...

Embodiment 3

[0027] Embodiment 3: Research on enzymatic properties of acetoin reductase

[0028] The crude enzyme solution was purified by Ni-NTA column to obtain pure AR / BDH. The specific enzyme activity of the purified enzyme solution in the AR direction was 140.92U / g, and the specific activity in the BDH direction was 112.56U / g, and the purification factor reached 18.18 times, the recovery rate was 41.95%.

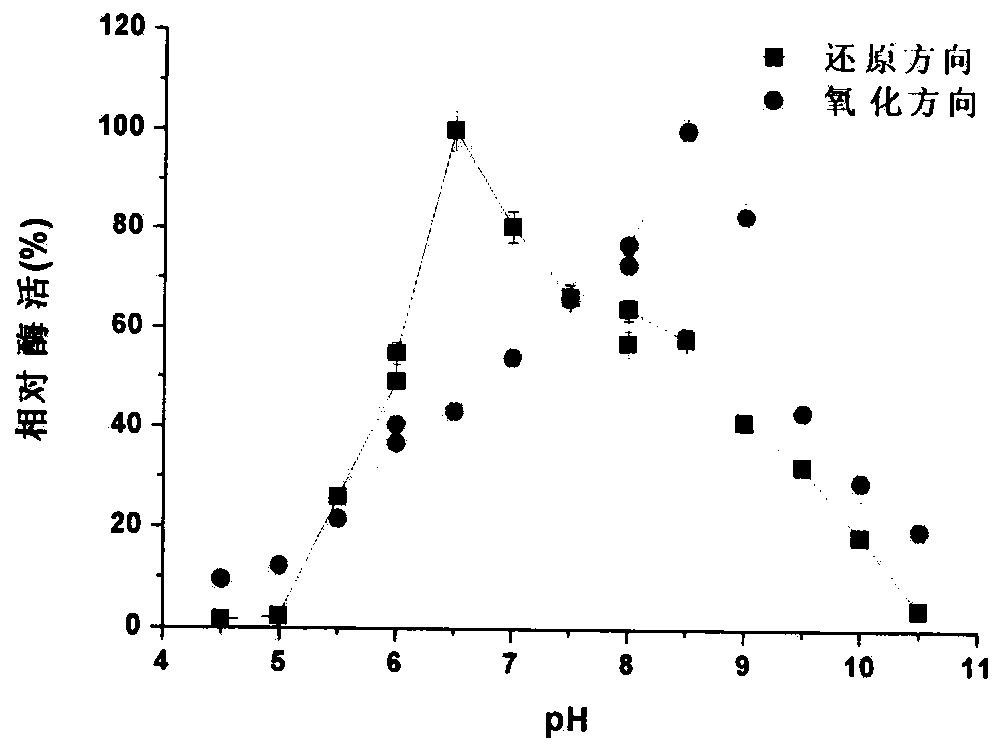

[0029] (1) Study on optimum pH

[0030] Prepare buffers with different pH gradients (pH4.5-5.5: 50mM sodium acetate-acetic acid buffer; pH5.5-9.0: 50mM sodium phosphate buffer; pH9.0-10.5: 50mM glycine-sodium hydroxide buffer, each 0.5pH as a gradient), with 100mM2,3-butanediol and 5mM NAD + (or 50mM acetoin and 5mM NADH) were mixed, 2mL of different pH substrate buffers were reacted with 20μL of enzyme solution, and the relative activities of enzymes under different pH conditions were measured and compared. The results showed that the activity of the enzyme in the direction of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com