A kind of acrylonitrile-butadiene-styrene (abs) powder with dual-binary particle size distribution that can be used for 3D printing and its preparation method

A technology of acrylonitrile and styrene, applied in the field of polymers, can solve problems affecting the performance of 3D printing formed parts, complicated process flow, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

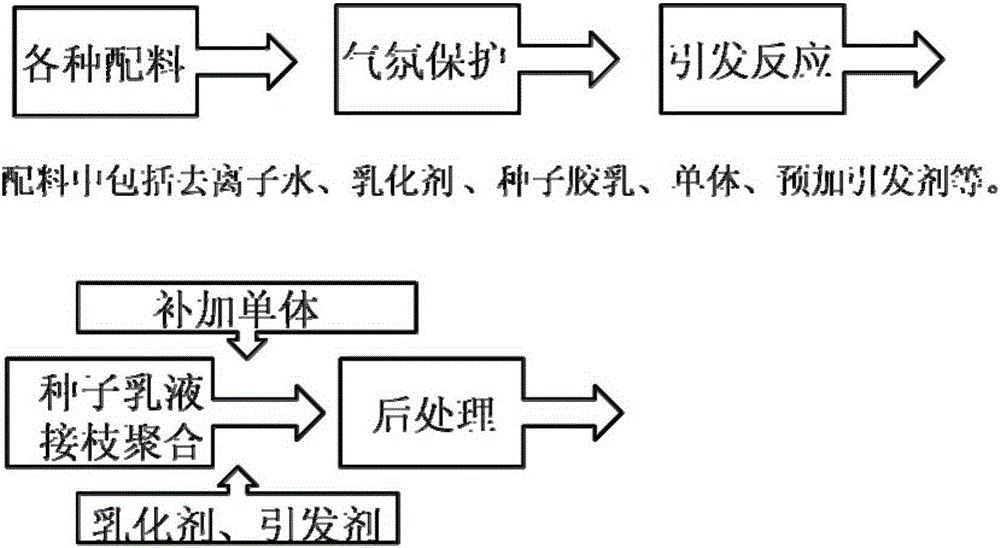

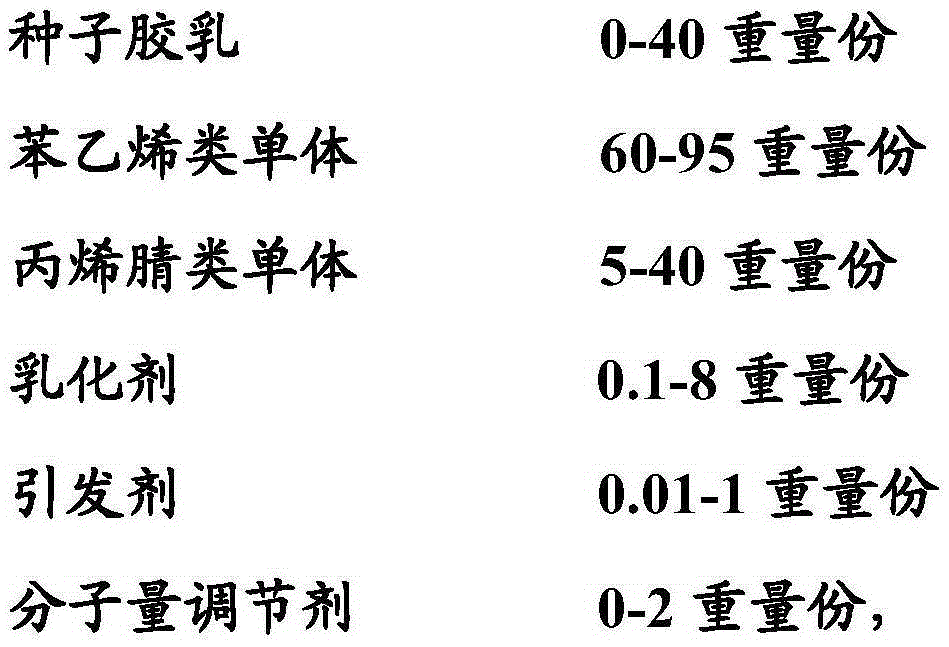

Method used

Image

Examples

Embodiment 1

[0100] The first step: the polybutadiene latex particle (1) that the mass fraction is 90 deionized water, the mass fraction is 18, its particle diameter is 20 microns, and the mass fraction is 0.2 oleic acid The sodium emulsifier is introduced into the N2-protected polymerization reactor, and the styrene and acrylonitrile monomers with a weight fraction of 15 and 3 are also introduced into the reactor; dodecylmercaptan with a mass fraction of 0.1 is added as a molecular weight regulator , the initiation system comprises the sodium pyrophosphate that the mass fraction is 0.15, the glucose that the mass fraction is 0.11, the ferrous sulfate that the mass fraction is 0.02, and the hydroperoxide cumene (initial throw initiator) that the mass fraction is 0.14 ), the reaction temperature was raised to 72°C to start the reaction.

[0101] In addition, a part of the monomer mixed emulsion added later is prepared; wherein the deionized water containing 200 parts by weight, the sodium o...

Embodiment 2

[0106] The first step: the polybutadiene latex particle (1) that the mass fraction is 80 deionized water, the mass fraction is 18, its particle diameter is at 15 microns, and the mass fraction is 0.4 oleic acid The sodium emulsifier is introduced into the N2 protected polymerization reactor, and the styrene and acrylonitrile monomers with a weight fraction of 18 and 5 are also introduced into the reactor; Sodium pyrophosphate of 0.15, the glucose of 0.11 in mass fraction, the ferrous sulfate of 0.02 in mass fraction, and the hydroperoxide cumene (initiator) of 0.14 in mass fraction, the reaction temperature rises to 72 ℃ and begins reaction.

[0107] In addition, a part of the monomer mixed emulsion added later is prepared; wherein the deionized water containing 200 parts by weight, sodium oleate of 1 part by weight, styrene of 80 parts by weight, and propylene of 15 parts by weight Nitrile, the dodecyl mercaptan that parts by weight are 0.5, the sodium pyrophosphate that par...

Embodiment 3

[0112] Except that the total mass of styrene and acrylonitrile added in advance is increased to 33 parts by mass, and the total amount of styrene and acrylonitrile added subsequently is reduced to 85 parts by weight. In the second step, the antioxidant is 1010 powder, Prepared according to the same method as in Example 1, its physical properties are tested as follows.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com