Water-resistant magnesium oxysulfate fire-proof plate and manufacturing method thereof

A technology of fireproof board and magnesium oxysulfide, which is applied in the field of fireproof board production, can solve problems such as the inability to meet the application requirements of construction projects, achieve high strength and safety, and expand the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

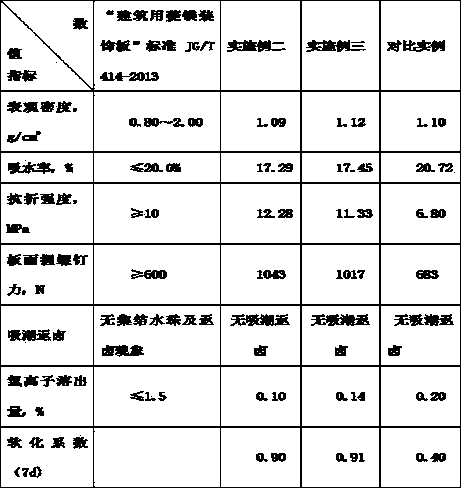

Examples

Embodiment 1

[0026] Mix the raw materials in the following mass percentages evenly to obtain the modifier (magnesium oxysulfate water resistance enhancer) of the present invention:

[0027] Silica fume 10%

[0028] Silicone water repellent powder 20%

[0029] Sucrose 38%

[0030] Humic Acid 32%.

Embodiment 2

[0032] Slurry formula:

[0033] Lightly burned magnesia powder 100kg Magnesium sulfate solution (density is 1.22g / cm 3 ) 111kg

[0034] Magnesium oxysulfide anti-water enhancer 1kg Talc powder (325 mesh) 30kg

[0035] Closed-cell perlite (30 mesh size) 5kg

[0036] Reinforcement material: medium alkali glass fiber cloth (close to the slurry) and non-woven fabric (close to the surface)

[0037] The decorative veneer is wood veneer, and the bonding material is white latex.

[0038] Production steps:

[0039] a. Preparation of modified magnesium oxysulfide cement slurry

[0040] Add light-burned magnesium oxide powder into the magnesium sulfate solution, mix and stir evenly, and add magnesium oxysulfate water-resistant enhancer to obtain a clean slurry; mix the clean slurry with talcum powder and closed-cell perlite at a stirring speed of 70 rpm, and stir Obtain the modified magnesium oxysulfide cement slurry after uniformity;

[0041] b. Spread the slurry obtained in step...

Embodiment 3

[0046] Slurry formula:

[0047] Lightly burned powder 100kg Magnesium sulfate solution (density 1.22g / cm 3 ) 114kg

[0048] Magnesium oxysulfate anti-water enhancer 1kg fly ash (200 mesh) 30kg

[0049] Closed-cell perlite (30 mesh size) 5kg

[0050] Reinforcement material: medium alkali fiberglass cloth (close to the slurry) and non-woven fabric (close to the surface).

[0051] The decorative veneer is PVC veneer, and the bonding material is one-component polyurethane glue.

[0052] Except that the active packing used is different, the manufacturing steps are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com