A kind of prefabricated fence and preparation method thereof

A prefabricated and fenced technology, which is applied in the direction of fences, building types, buildings, etc., can solve the problems of economic performance, difficult product promotion value, inability to form a dispersed self-leveling state, high cement content and silica fume content, and reduce manual management. and environmental pollution, reduce construction labor intensity, and reduce the effect of comprehensive construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

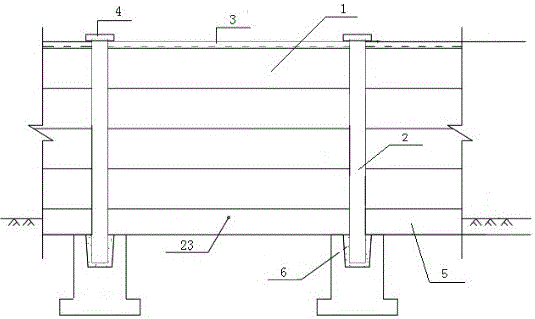

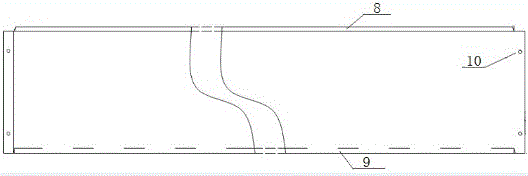

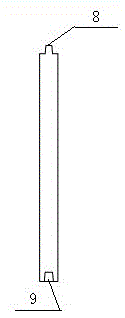

[0067] Such as figure 1 As shown, a prefabricated fence includes a wall panel 1, a wind-resistant column 2, a top pressure 3, a column cap 4, a ground beam 5 and a cup base 6, and the cup base 6 is embedded with a wind-resistant column 2, The column cap 4 is fixed on the wind-resistant column 2, and the wall panels 1 are connected between the adjacent wind-resistant columns 2, the top of the wall panel 1 is fixed with a top 3, and the bottom of the wall panel 1 is fixed with a ground beam 5.

[0068] The wall panel is poured with fluid ultra-high performance inorganic powder concrete, and the fluid ultra-high performance inorganic powder concrete includes the following raw material components in parts by weight:

[0069] 575 parts of low-alkali Portland cement with an average particle size of 30-60 μm;

[0070] Average particle size 0.18μm, SiO 2 105 parts of silica fume with content ≥85%;

[0071] 130 parts of Class II fly ash with an average particle size of 20-40 μm;

...

Embodiment 2

[0093] Except that the parts by weight of each raw material component of the fluidized ultra-high performance inorganic powder concrete are different, other conditions are the same as in Example 1;

[0094] The fluid ultra-high-performance inorganic powder concrete includes the following raw material components in parts by weight:

[0095] 500 parts of low-alkali Portland cement or ordinary Portland cement with an average particle size of 30-60 μm;

[0096] Average particle size 0.18μm, SiO 2 85 parts of silica fume with content ≥85%;

[0097] 115 parts of Class II fly ash with an average particle size of 20-40 μm;

[0098] 175 parts of S95 grade or above slag powder with an average particle size of 10-30 μm;

[0099] 1050 parts of river sand with a particle size of 0.16~4.75mm and a mud content of less than 0.5%;

[0100] 26 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0101] 130 parts of water;

[0102] 100 parts of copper-...

Embodiment 3

[0104] Except that the parts by weight of each raw material component of the fluidized ultra-high performance inorganic powder concrete are different, other conditions are the same as in Example 1;

[0105] The fluid ultra-high-performance inorganic powder concrete includes the following raw material components in parts by weight:

[0106] 650 parts of low-alkali Portland cement or ordinary Portland cement with an average particle size of 30-60 μm;

[0107] Average particle size 0.18μm, SiO 2 120 parts of silica fume with content ≥85%;

[0108] 145 parts of Class II fly ash with an average particle size of 20-40 μm;

[0109] 215 parts of slag powder above grade S95 with an average particle size of 10-30 μm;

[0110] 1250 parts of river sand with a particle size of 0.16~4.75mm and a mud content of less than 0.5%;

[0111] 32 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0112] 145 parts of water;

[0113] 140 parts of copper-coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com