A low temperature boiling chlorination system

A chlorination system and boiling chlorination furnace technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems affecting the chlorination rate of chlorination production, short residence time of raw materials, and excessive local pressure, etc. Reduce the static pressure and diffusion resistance in the furnace, which is beneficial to continuous operation and suppresses the effect of reverse back mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

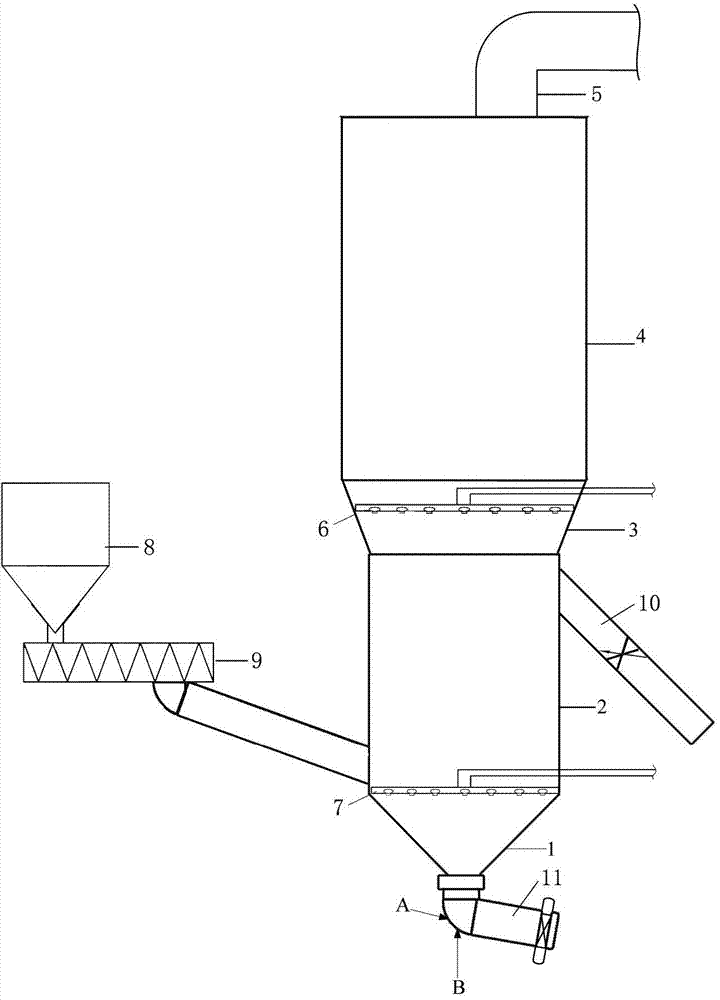

[0024] Hereinafter, the low temperature boiling chlorination system according to the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments. It should be noted that the carbide slag mentioned in the present invention is the blast furnace slag obtained by smelting ilmenite (such as vanadium-titanium magnetite) through blast furnace smelting and then forms after carbonization, which can contain 10-14wt% titanium carbide (TiC ).

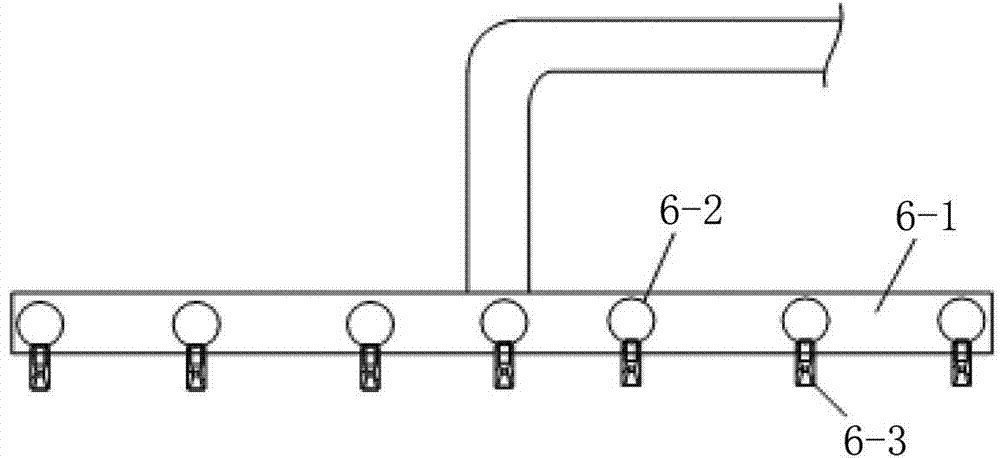

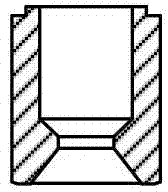

[0025] figure 1 It is a schematic diagram of the front view structure of the low temperature boiling chlorination system of the exemplary embodiment of the present invention. figure 2 Yes figure 1 The enlarged schematic diagram of the relationship between the first gas distributor and the pipeline connection in . image 3 Yes figure 2 An enlarged schematic view of the middle nozzle. Figure 4 Yes figure 2 bottom view.

[0026] like figure 1 As shown, in an exemplary embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com