Method for synthesizing molecular sieve by using solid phase

A solid-phase synthesis, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc. The effect of reducing energy consumption, improving efficiency and reducing the cost of reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: ITQ-13 molecular sieve with pure silicon phase was synthesized in solid phase with hexamethyldiammonium bromide as a directing agent in a solvent-free method.

[0042] After mixing 0.54g of water with 1.22g of sodium metasilicate, recrystallize to form sodium metasilicate containing three crystal waters; Mix hexamethyldiammonium bromide and 0.59g ammonium fluoride in an agate mortar and grind for 5-10 minutes until the mixture is uniform, then put the ground mixture into a glass tube and seal it with flame; finally After the sealed glass tube was crystallized in an oven at 180°C for 4 weeks, the reaction product was washed and placed in an oven at 60°C for 12 hours to completely dry to finally obtain the product.

[0043] The proportioning of reaction raw material is as follows:

[0044] 1.0Na 2 SiO 3 ·3H 2 O:1.0SiO 2 (Silica): 0.15HMBr 2 : 1.6NH 4 f

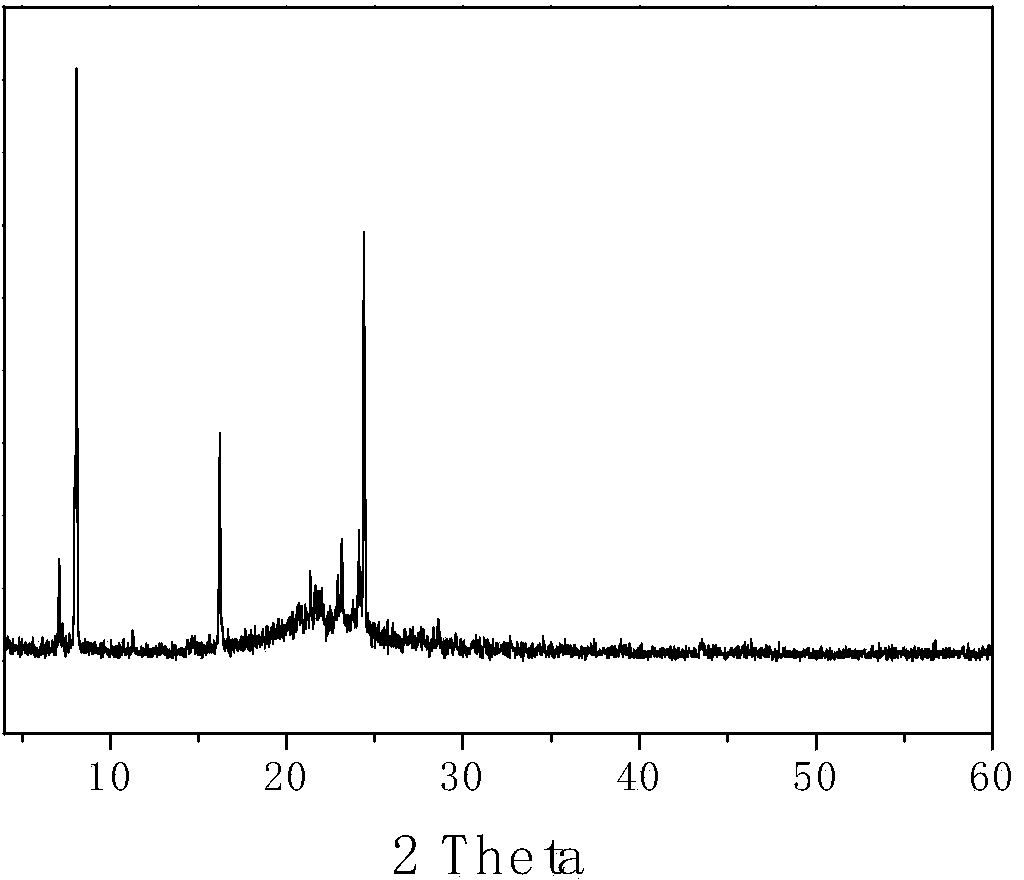

[0045] X-ray diffraction ( figure 1 ) analysis of its structure as ITQ-13 zeolite molecular sieve, ...

Embodiment 2

[0046] Embodiment 2: Tetrapropylammonium bromide is the F-ZSM-5 molecular sieve of pure silicon phase synthesized by solid phase method without solvent as the guiding agent.

[0047] After mixing 0.54g of water with 1.22g of anhydrous sodium metasilicate, recrystallize to form sodium metasilicate containing three crystal waters; then mix 1.76g of trihydrate sodium metasilicate with 0.56g of white carbon black at room temperature, Mix 0.53g tetrapropylammonium bromide and 0.59g ammonium fluoride and place in an agate mortar, grind for 5-10 minutes until the mixture is uniform, then put the ground mixture into a glass tube and seal it with flame; Finally, the sealed glass tube was crystallized in an oven at 180° C. for 4 weeks, and the reaction product was washed and placed in an oven at 60° C. for 11 hours until it was completely dried to finally obtain the product.

[0048] The proportioning of reaction raw material is as follows:

[0049] 1.0Na 2 SiO 3 ·3H 2 O:1.0SiO 2 (...

Embodiment 3

[0051] Embodiment 3: Tetraethylammonium bromide is the F-ZSM-5 molecular sieve of pure silicon phase solid-phase synthesis as the directing agent solvent-free method

[0052] After mixing 1.08g of water with 1.22g of anhydrous sodium metasilicate, recrystallize to form sodium metasilicate containing six crystal waters; then mix 2.30g of hexahydrate sodium metasilicate with 0.56g of white carbon black at room temperature, Mix 0.88g of tetraethylammonium bromide and 0.59g of ammonium fluoride and place in an agate mortar, grind for 5-10 minutes until the mixture is uniform, then put the ground mixture into a glass tube and seal it with flame; Finally, place the sealed glass tube in an oven at 180°C for crystallization for 4 weeks, wash the reaction product, and place it in an oven at 60°C for about 10 hours to completely dry to finally obtain the product. The proportioning of reaction raw material is as follows:

[0053] 1.0Na 2 SiO 3 ·6H 2 O:1.0SiO 2 (Silica): 0.60TEABr: 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com