Method for preparing telluric acid

A technology of telluric acid and tellurium powder, applied in the field of compound synthesis, can solve the problems of complex impurity removal process, high cost, unfavorable application and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 250.0g of 3N tellurium powder with a particle size of less than 325 microns into a 2L quartz beaker containing 500g of deionized water and 500g of 50% industrial-grade hydrogen peroxide under stirring, and then heat up the resulting mixed solution to 95°C. After the temperature rises to a high temperature, the reaction is more violent. After stirring for 2 hours, the solution becomes clear and transparent, and then the solution is filtered while it is hot to obtain a telluric acid solution;

[0036] After suction filtration, heat the obtained solution to 100°C, evaporate the specific gravity of the solution to 1.85g / mL, then stop heating, and after cooling to room temperature, a large number of crystals precipitate out, and the crystals are obtained after filtration;

[0037] The obtained crystals were dried in a vacuum oven at 60°C for 12 hours to obtain a telluric acid sample.

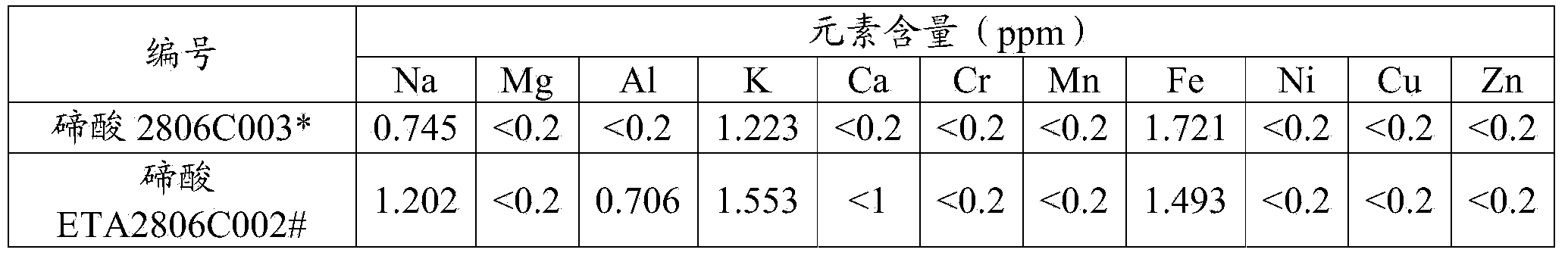

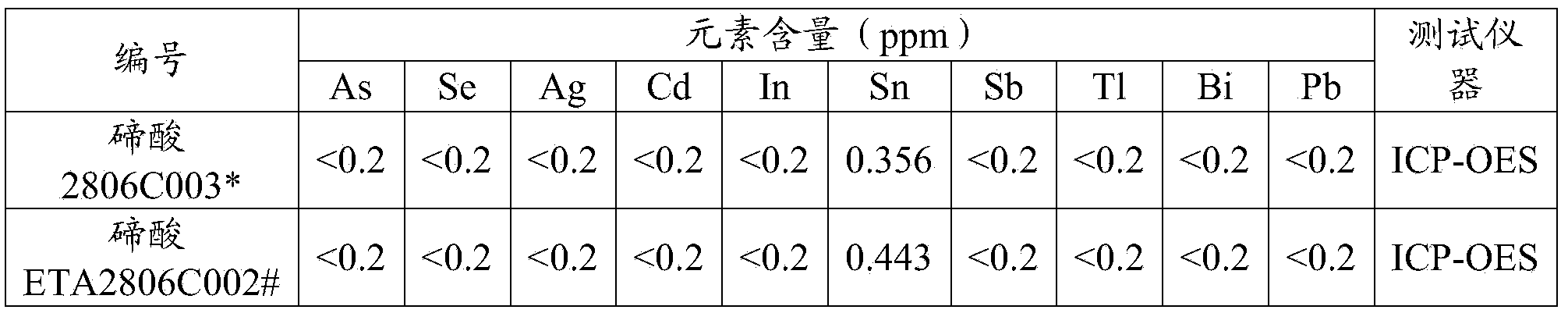

[0038] The mass of the telluric acid sample obtained by weighing in the present invent...

Embodiment 2

[0049] Add 250.0g of 3N tellurium powder with a particle size of less than 325 microns into a 2L quartz beaker containing 750g of deionized water and 500mL of 50% industrial-grade hydrogen peroxide under stirring, and then heat up the resulting mixed solution to 100°C. After the temperature rose to 100°C, the reaction was more violent. After stirring for 2.5 hours, the solution became clear and transparent, and then the solution was filtered while it was hot to obtain a telluric acid solution;

[0050] After suction filtration, heat the obtained solution to 105°C, evaporate the specific gravity of the solution to 1.90g / mL, then stop heating, and after cooling to room temperature, a large number of crystals precipitate out, and the crystals are obtained after filtration;

[0051] After the obtained crystals were vacuum-dried at 70°C for 10 h, a telluric acid sample was obtained.

[0052] The mass of the telluric acid sample obtained by weighing in the present invention is 339.4...

Embodiment 3

[0056] Add 250.0g of 3N tellurium powder with a particle size of less than 325 microns into a 2L quartz beaker containing 1166g of deionized water and 500mL of 50% industrial-grade hydrogen peroxide under stirring, then heat up the resulting mixed solution to 110°C, and wait After the temperature rose to 110°C, the reaction was more violent. After stirring for 3 hours, the solution became clear and transparent, and then the solution was filtered while it was hot to obtain a telluric acid solution;

[0057] After suction filtration, heat the solution to 110°C to evaporate the specific gravity of the solution to 1.95g / mL, then stop heating, and after cooling to room temperature, a large number of crystals precipitate out, and the crystals are obtained after filtration;

[0058] After the obtained crystals were vacuum-dried at 80°C for 6 hours, a telluric acid sample was obtained.

[0059] The mass of the telluric acid sample obtained by weighing in the present invention is 347.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com