Belt conveyor protection device for coal mine

A technology of belt conveyor and protection device, applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of complex danger, inconvenient operation, huge work line, etc., and achieve strong flexibility, scalability and convenience. Timely maintenance, fully functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

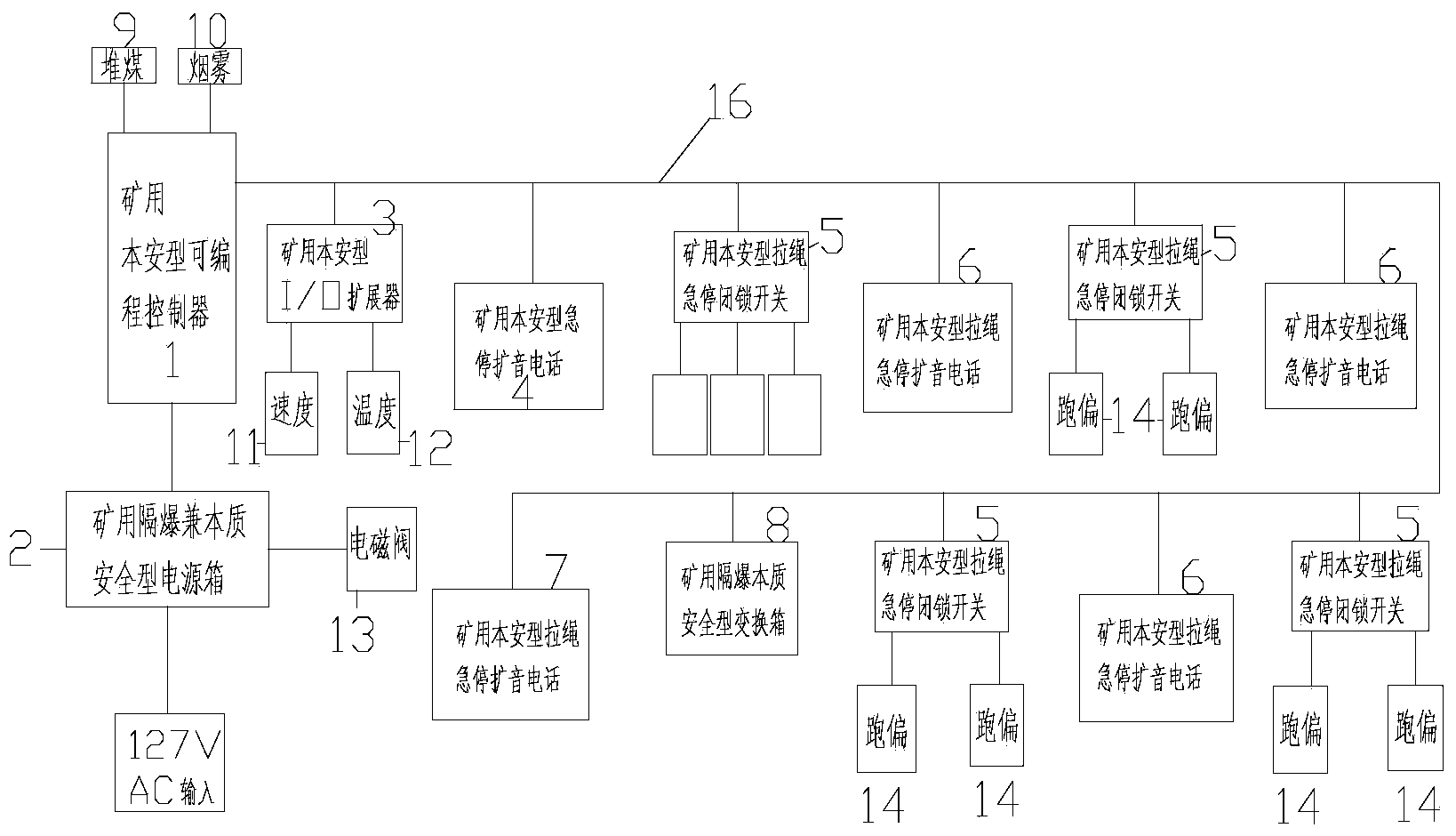

[0012] Such as figure 1 The coal mine belt conveyor protection device shown is composed of a mine-used intrinsically safe programmable controller 1 and a signal detection unit connected to its port by a cable. The mine-used intrinsically safe programmable controller 1 is explosion-proof for mines Intrinsically safe power box 2 is connected to the power supply to supply power to the belt conveyor protection device for this coal mine. The input power is 127V AC. The signal detection unit includes a sensor and a loudspeaker phone. The sensor is installed at the unloading place of the conveyor head tape Or the coal stack sensor 9 in the coal bunker of the nose, the mine smoke sensor 10 arranged above the main driving drum of the conveyor, the speed detection sensor 11 arranged under the belt of the conveyor, the mining sensor arranged at the heat source 10-15mm The temperature sensor 12, the mining belt deviation sensor 14 arranged on both sides of the conveyor, and the mining intri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com