A rack pressure block for rack and pinion steering gear

A technology of rack and pinion and steering gear, applied in the field of auto parts manufacturing, can solve the shape and ideal shape error of the working surface of the tablet, the fluctuation of the gap between the gear and the rack of the steering gear assembly, and affect the smooth meshing of the rack and pinion transmission pair. It can reduce the production process, reduce the gap fluctuation, and reduce the weight obviously.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

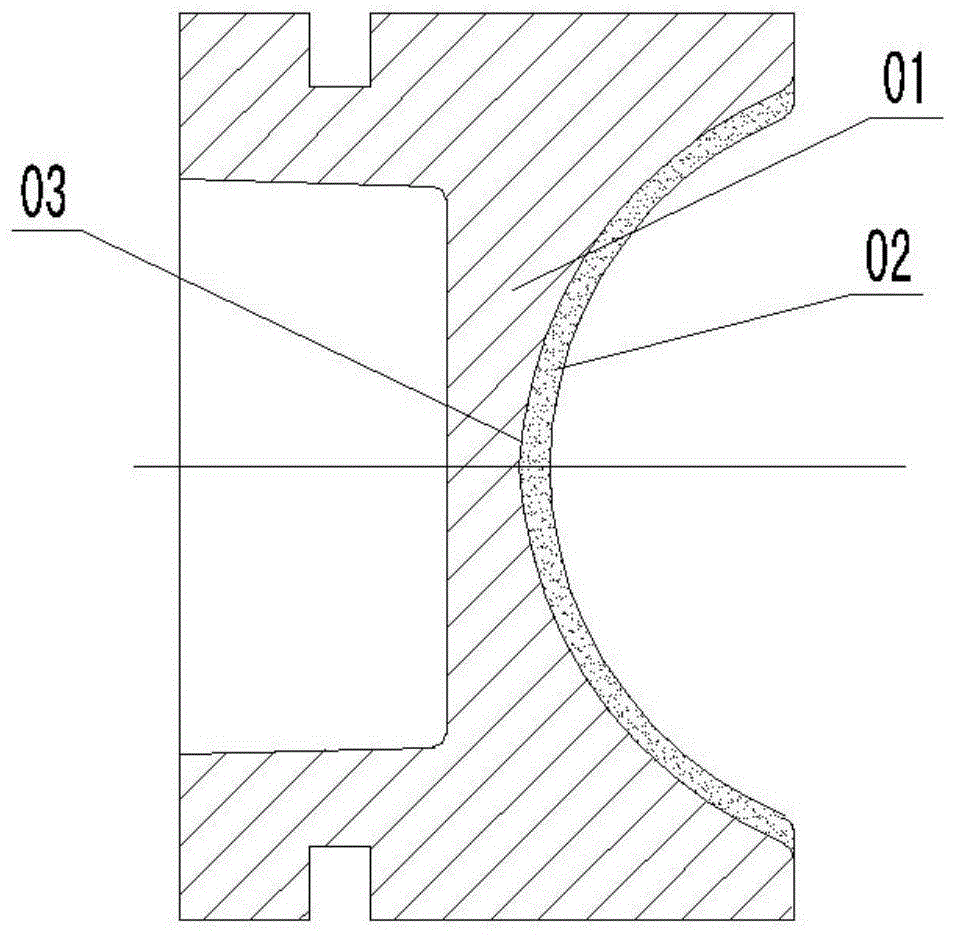

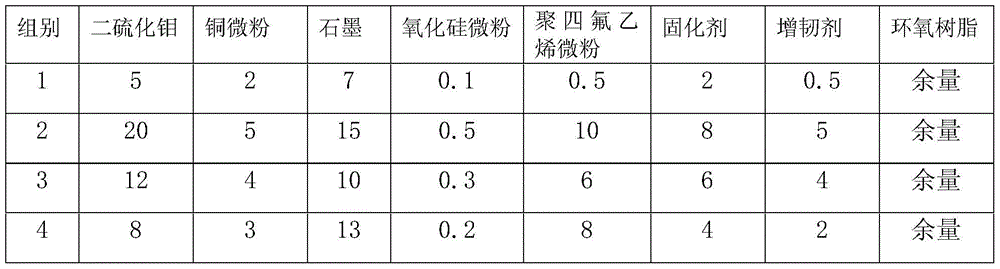

[0017] see figure 1 , the material of the substrate 01 of the rack press block in the present embodiment is aluminum alloy, the friction surface 03 of the substrate 01 and the counter rack is provided with an antifriction coating 02, and the material formula of the antifriction coating 02 is by mass percentage For: molybdenum disulfide 5-20%, copper powder 2-5%, graphite 7-15%, silicon oxide powder 0.1-0.5%, polytetrafluoroethylene powder 0.5-10%, curing agent 2-8%, toughening Agent 0.5-5%, the balance is epoxy resin.

[0018] The curing agent is an aliphatic amine curing agent or an imidazole latent curing agent; the toughening agent is a polyamide resin or a nitrile rubber resin; the aluminum alloy material of the substrate 01 is preferably: 2A12-T4 of the Al-Cu-Mg system or 2A14-T4; or 6061-T4 of Al-Mg-Si system; or ZL111T6 of casting AL-Si-Cu system; the thickness of anti-friction spraying layer 02 is 0.010-0.050mm.

[0019] The manufacturing process of the rack briquett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com