Manufacturing method of four-channel special-shaped deflection magnet in vacuum

A deflecting magnet and manufacturing method technology, applied in inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve the problems of difficult repeated positioning, high difficulty in shape control, difficult control of relative position, etc., and achieve stable magnet structure. Good performance, stable magnetic field performance, good magnetic field index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

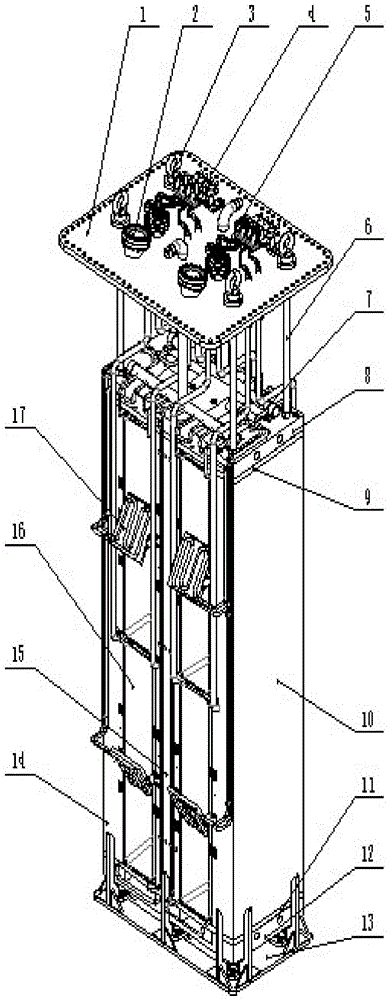

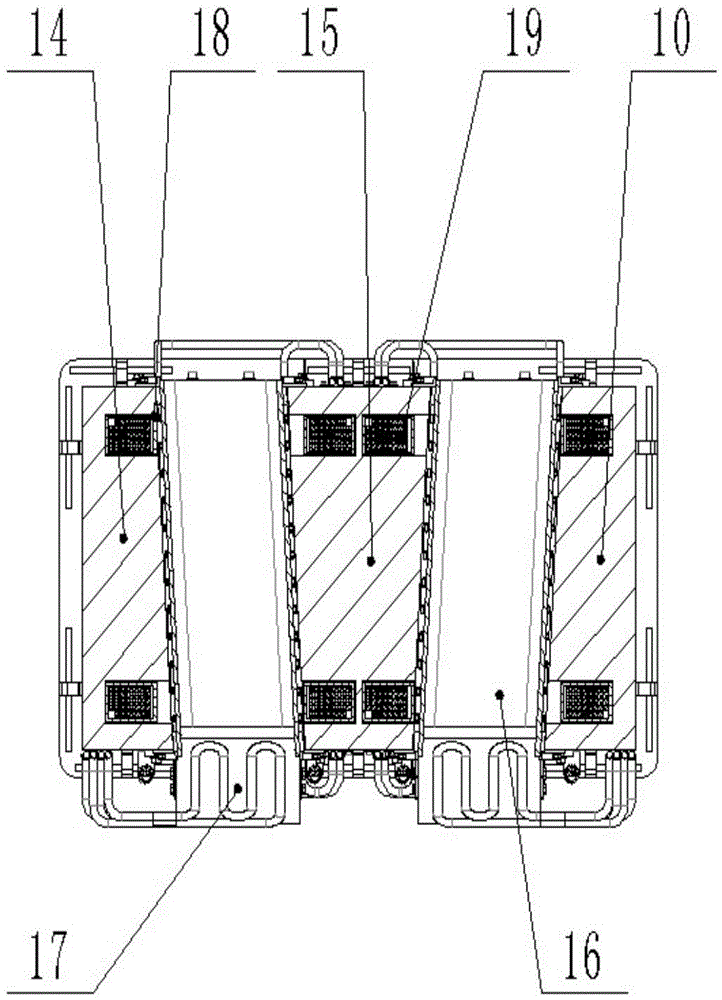

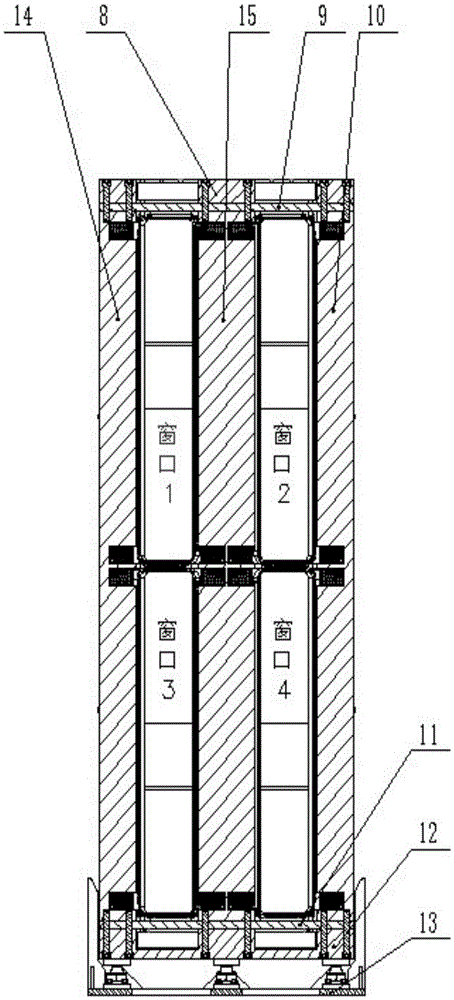

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0033] Such as Figures 1 to 5 As shown, the manufacturing method of the four-channel special-shaped deflection magnet in the vacuum is characterized in that it comprises the following steps:

[0034] (1), the main body of the iron core of the deflection magnet is divided into five parts: the left magnet 10, the right magnet 14, the middle magnet 15, the upper connecting plate 9, and the lower connecting plate 10, and the five parts are processed by forging and heat treatment to improve the magnetic properties; The slab forging requires a forging ratio of 1:1.5 to ensure that there are no pores, slag inclusions, and interlayer defects inside. The heat treatment process is: heat preservation at 900°C±10°C for 1 hour,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com