Finishing device and finishing method for aircraft ear-type door hinge hole

A door hinge and lug technology, which is applied in the field of aircraft lug-type door hinge hole finishing device, can solve problems such as low quality and inability to achieve coaxiality, so as to improve the service life, improve the quality and precision of the hole, The effect of ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

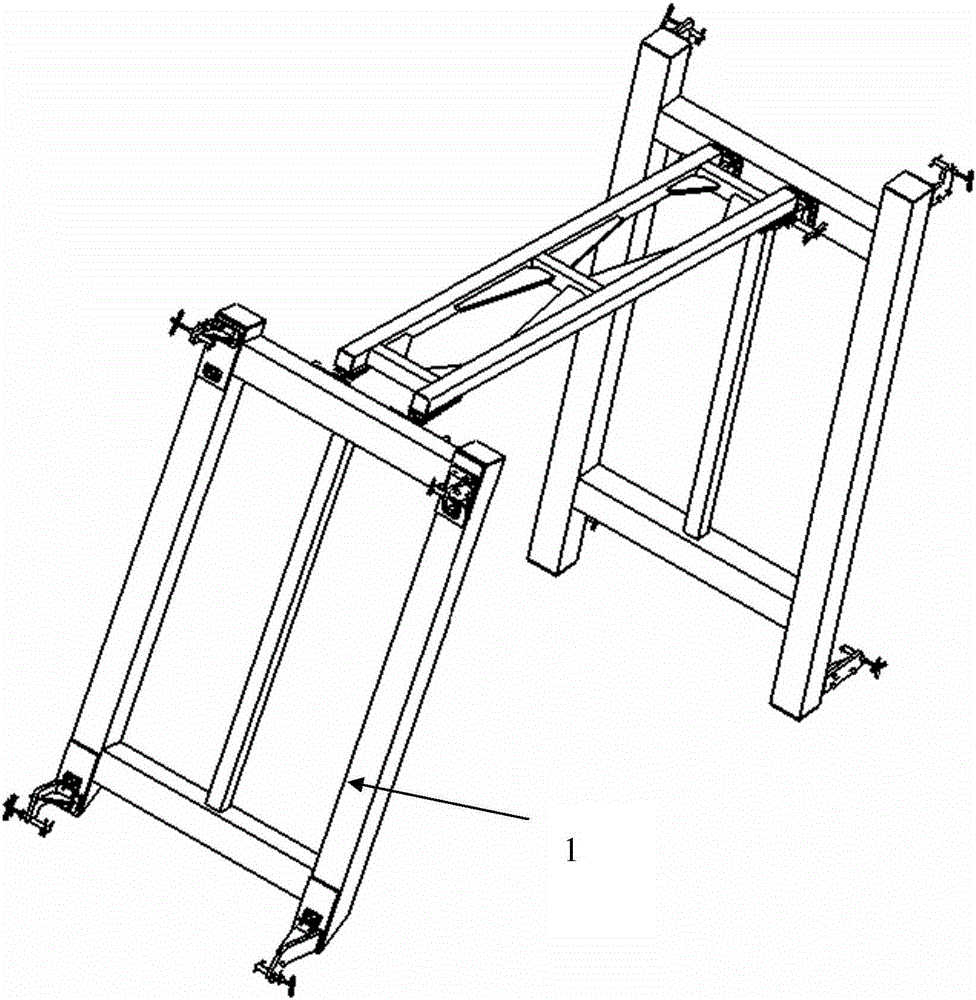

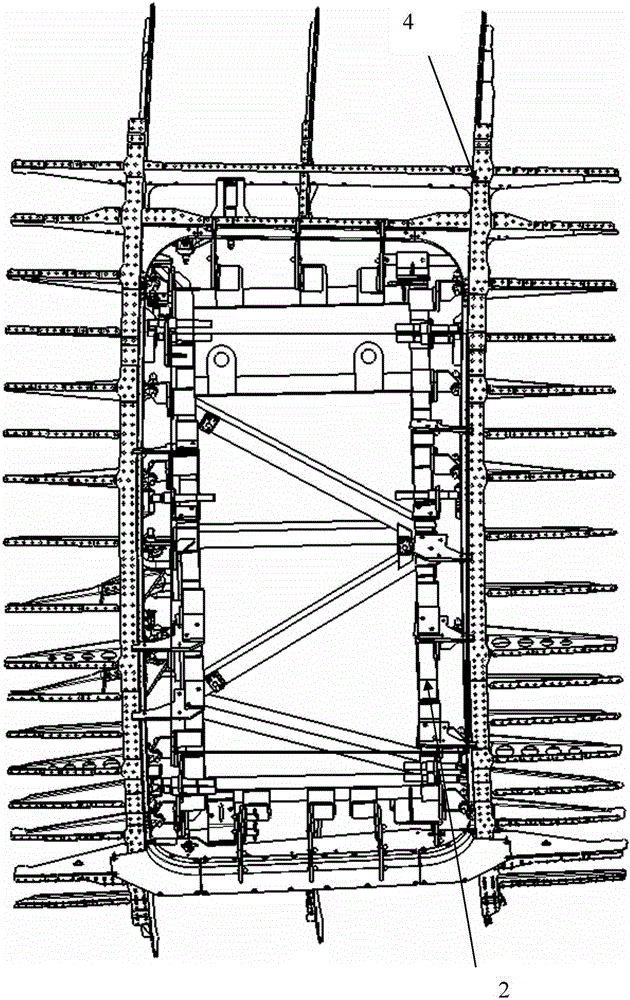

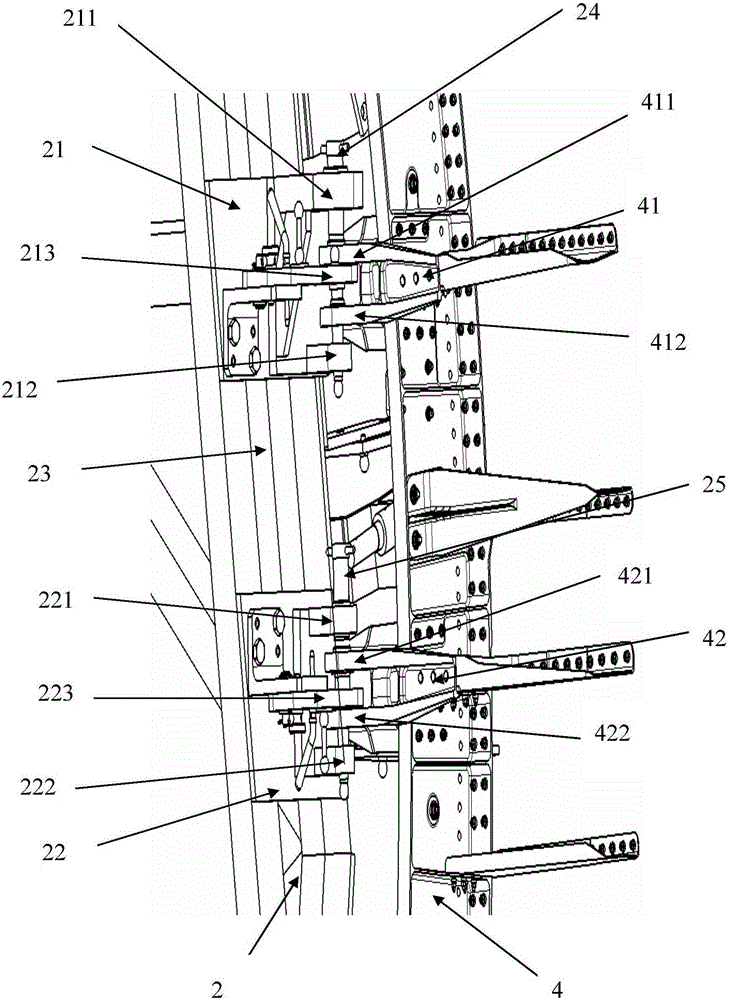

[0030] like Figure 1-5 As shown, the device for finishing the hinge hole of an aircraft ear-type door according to the present invention includes a support tool 1 , a hinge joint positioning tool 2 , a cutter 3 , and a door frame 4 . The support tool 1 is used to support the door frame 4 to the correct position. The hinge joint positioning tool 2 has a bracket 23, an upper hinge joint positioning mechanism 21 and a lower hinge joint positioning mechanism 22, and the upper hinge joint positioning mechanism 21 includes a drilling template I211, a drilling template II 212, a drilling template I211 and a drilling template I211 and a drilling template I211 and a drilling template I211 fixed on the bracket 23. The control block I213 and the positioning pin I24 between the drilling template II212 and movably connected with the bracket 23, the drilling template I211 and the drilling template II212 respectively have through holes I214 and through holes II215, and the positioning pins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com