A kind of air purification material with high catalytic oxidation activity

An air purification material and catalytic oxidation technology, which is applied in the direction of physical/chemical process catalysts, other chemical processes, chemical instruments and methods, etc., can solve problems such as poor practicability, high cost, and difficulty in meeting the use of ultraviolet light strips, and achieve Wide application range, no need for heating, convenient application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

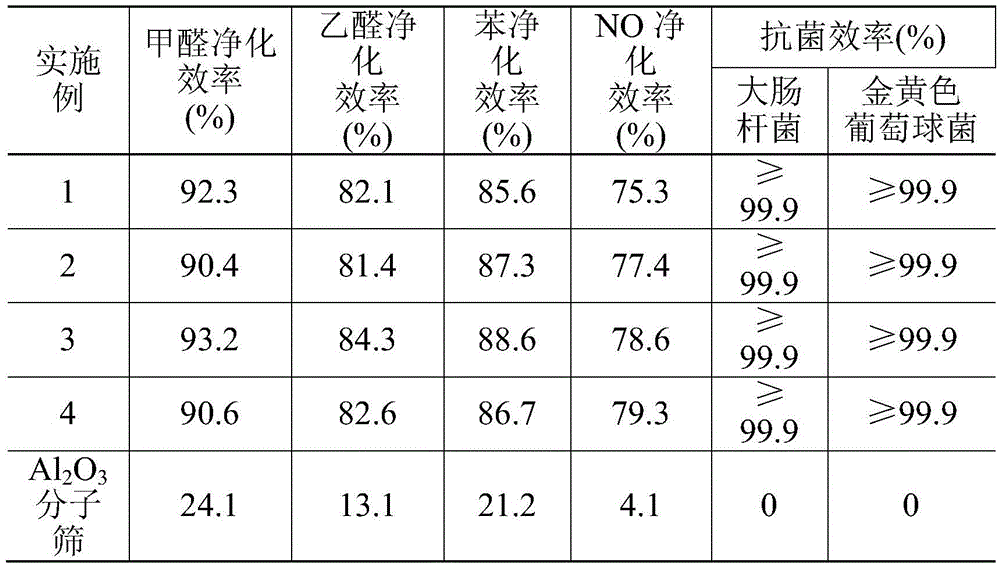

Examples

Embodiment 1

[0025] Mix butyl titanate and absolute ethanol uniformly at a volume ratio of 1:4.4 to make liquid A, and then uniformly mix deionized water, absolute ethanol and glacial acetic acid at a volume ratio of 1:1.3:0.24 to form a mixed liquid B , Add solution A dropwise (at a rate of 3 mL / min) to the prepared solution B in a water bath at 40°C, and the volume ratio of solution A to solution B in the mixed solution is 2.4:1. At the same time, a constant temperature magnetic stirrer was used for rapid stirring to hydrolyze the butyl titanate. After continuous stirring for about 3 hours, a white transparent TiO2 gel was formed after filtration.

[0026] Mix and stir potassium permanganate, manganese acetate and water evenly according to the mass ratio of 1:1.4:6.5, transfer the mixed solution into a reaction kettle with a polytetrafluoroethylene lining, and then add distilled water to adjust to the inner lining of the reaction kettle. 65% of the volume, sealed, and placed in a vacuum...

Embodiment 2

[0030] Mix butyl titanate and absolute ethanol uniformly at a volume ratio of 1:4.2 to make liquid A, and then uniformly mix deionized water, absolute ethanol and glacial acetic acid at a volume ratio of 1:1.2:0.22 to form a mixed liquid B , Add solution A dropwise (at a rate of 3 mL / min) to the prepared solution B in a water bath at 40°C, and the volume ratio of solution A to solution B in the mixed solution is 2.5:1. At the same time, a constant temperature magnetic stirrer was used for rapid stirring to hydrolyze the butyl titanate. After continuous stirring for about 2h, a white transparent TiO2 gel was formed after filtration.

[0031] Mix potassium permanganate, manganese acetate and water evenly according to the mass ratio of 1:1.5:6.3, transfer the mixed solution into a reaction kettle with a polytetrafluoroethylene lining, and then add distilled water to adjust to the inner lining of the reaction kettle. 70% of the volume, sealed, and placed in a vacuum oven, heated ...

Embodiment 3

[0035] Mix butyl titanate and absolute ethanol uniformly at a volume ratio of 1:4.0 to make liquid A, and then uniformly mix deionized water, absolute ethanol and glacial acetic acid at a volume ratio of 1:1:0.20 to form mixed liquid B , Add solution A dropwise (at a rate of 3 mL / min) to the prepared solution B in a water bath at 40°C, and the volume ratio of solution A to solution B in the mixed solution is 2.3:1. At the same time, a constant temperature magnetic stirrer was used for rapid stirring to hydrolyze the butyl titanate. After continuous stirring for about 3 hours, a white transparent TiO2 gel was formed after filtration.

[0036]Mix and stir potassium permanganate, manganese acetate and water evenly according to the mass ratio of 1:1.5:6, transfer the mixed solution into a reaction kettle with a polytetrafluoroethylene lining, and then add distilled water to adjust to the inner lining of the reaction kettle. 60% of the volume, sealed, and placed in a vacuum oven, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com