Simultaneous desulfurization and denitrification method for flue gas

A technology for desulfurization, denitrification, and flue gas, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of high energy consumption and high ozone consumption, and achieve low operating costs, simple processes, and reduced processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Flue gas intake condition after dust removal: 4000Nm 3 / h,SO 2 The concentration is 1350ppm, the NO concentration is 600ppm, the temperature is 150°C, and the oxygen content in the flue gas is 7.5%.

[0051] The amount of ozone added: 2.6kg / h (0.5 times the molar amount of NO);

[0052] Absorbing liquid: industrial ammonia water (wherein the mass fraction of ammonia is 20%)+tap water;

[0053] Desulfurization and denitrification tower: spray tower;

[0054] Fe 3+ : Commercially available ferric sulfate, Fe in the prepared absorption solution 3+ The concentration is 8000ppm.

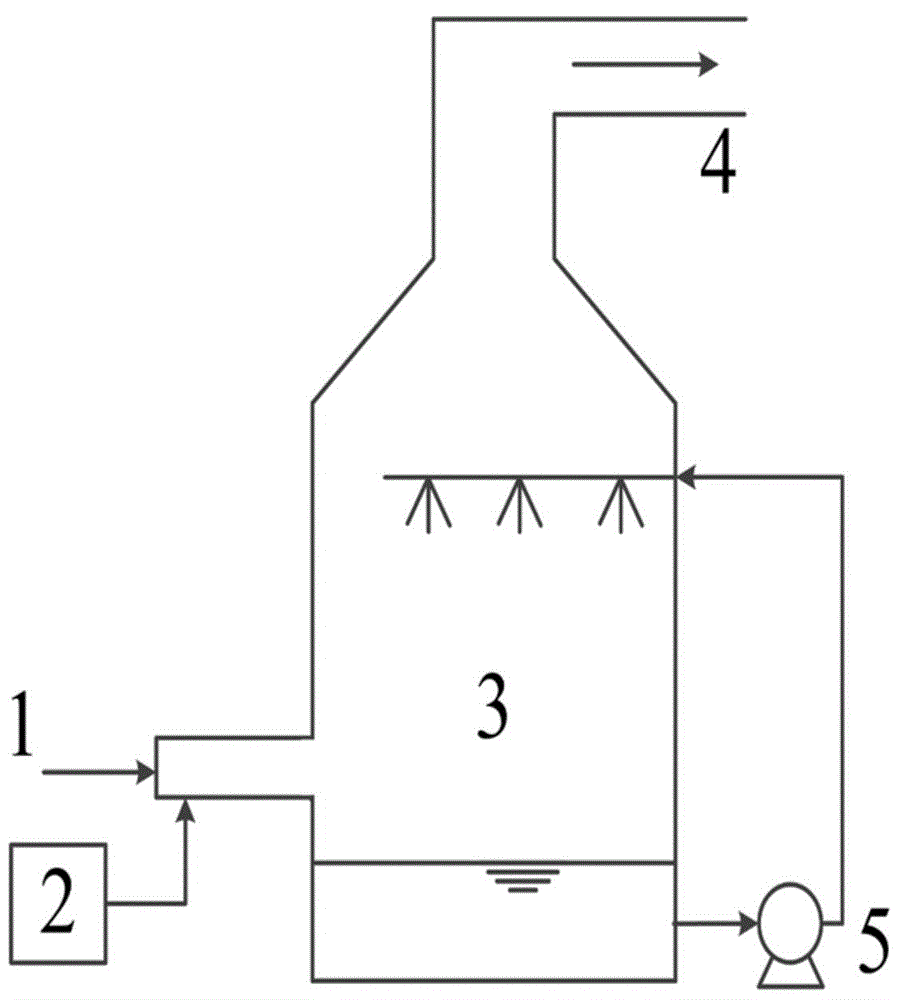

[0055] Desulfurization and denitrification devices such as figure 1 As shown, 1-intake flue, 2-ozone generator, 3-desulfurization and denitrification tower, 4-outlet flue, 5-absorption liquid circulation pump.

[0056] The flue gas is dedusted in the dust collector, the ozone is prepared in the ozone generator 2, the ozone is mixed with the flue gas in the intake flue 1, and reacted (pre-oxi...

Embodiment 2

[0062] Flue gas inlet conditions after dust removal: 12000Nm3 / h, SO 2 The concentration is 1000ppm, the NO concentration is 420ppm, the temperature is 120°C, and the oxygen content in the flue gas is 9.6%.

[0063] The amount of ozone added: 7.0kg / h (0.6 times the molar amount of NO);

[0064] Absorbing liquid: ammonium sulfite solution (wherein the mass fraction of ammonium sulfite is 20%)+tap water;

[0065] Desulfurization and denitrification tower: plate corrugated structured packing tower;

[0066] Fe 3+ : Commercially available ferric chloride, Fe in the prepared absorption solution 3+ The concentration is 45000ppm.

[0067] Flue gas dust removal, ozone is prepared in the ozone generator, ozone is mixed with flue gas in the intake flue, after the reaction (pre-oxidation), the mixed gas enters the desulfurization and denitrification tower from the bottom of the desulfurization and denitrification tower, and the absorption liquid comes from the desulfurization and deni...

Embodiment 3

[0070] Flue gas intake condition after dust removal: 7000Nm 3 / h,SO 2 The concentration is 730ppm, the NO concentration is 270ppm, the temperature is 110°C, and the oxygen content in the flue gas is 8.0%.

[0071] The amount of ozone added: 1.4kg / h (0.3 times the molar amount of NO);

[0072] Absorbing liquid: ammonium carbonate solution (wherein the mass fraction of ammonium carbonate is 40%)+tap water;

[0073] Desulfurization and denitrification tower: spray tower;

[0074] Fe 3+: Commercially available ferric sulfate, Fe in the prepared absorption solution 3+ The concentration is 30000ppm.

[0075] Flue gas dust removal, ozone is prepared in the ozone generator, ozone is mixed with flue gas in the intake flue, after the reaction (pre-oxidation), the mixed gas enters the desulfurization and denitrification tower from the bottom of the desulfurization and denitrification tower, and the absorption liquid comes from the desulfurization and denitrification tower. It is sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com