Composition for facial repair and preparation method thereof

A facial repairing and composition technology, applied in the field of facial repairing compositions, can solve problems such as inability to resist chemical factors, loss of protective properties of the stratum corneum, improper use by consumers, etc., to remove free radicals and harmful substances, and enhance Good penetration rate and embedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

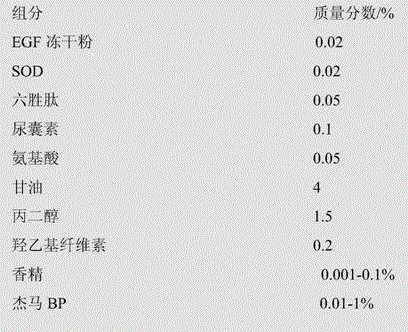

[0024] This embodiment is for restoring balance water, and its formula is:

[0025]

[0026]

[0027] Preparation Process:

[0028] (1) Encapsulate 0.02g EGF freeze-dried powder and 0.02g SOD with liposomes to obtain EGF liposomes and SOD liposomes, and then place them in a water bath at 60℃ for 30 minutes;

[0029] (2) Wrap 0.05g hexapeptide and 0.1g allantoin with nano-microcapsules to obtain hexapeptide microcapsules and allantoin microcapsules, and then place them in a water bath at 60°C for 30 minutes;

[0030] (3) Weigh out amino acids, glycerin, propylene glycol, and hydroxyethyl cellulose, add an appropriate amount of water, and dissolve and swell until clear while stirring. Slowly add items (1) and (2) to the above dissolving solution, and then add flavor, Stir the preservative (Genma BP) evenly, make up the water to 100.0g, and restore the balance water.

Embodiment 2

[0032] This example is a repair cream, and its formula is:

[0033]

[0034] Preparation Process:

[0035] (1) Encapsulate 0.1g EGF freeze-dried powder and 0.15g SOD with liposomes to obtain EGF liposomes and SOD liposomes, and then place them in a 60℃ water bath for 30 minutes;

[0036] (2) Wrap 0.2g of seaweed active peptide and 0.2g of allantoin with nano microcapsules to obtain seaweed active peptide microcapsules and allantoin microcapsules, and then place them in a water bath at 60°C for 30 minutes;

[0037] (3) Mix the oil phase raw materials and heat to 70°C, heat the water phase raw materials to 60°C, add the oil phase to the water phase, and add items (1) and (2) to the water phase respectively. Stir and emulsify, add flavor and preservatives after cooling down, and stir evenly to obtain repair cream.

Embodiment 3

[0039] This example is a repair emulsion, and its formula is:

[0040]

[0041] Preparation Process:

[0042] (1) Use liposomes to embed 0.05g EGF and 0.15g small molecule collagen peptides to obtain EGF liposomes and small molecule collagen peptide liposomes, and then place them in a water bath at 60°C for 30 minutes;

[0043] (2) Wrap 0.05g SOD and 0.15g allantoin with nano microcapsules to obtain SOD microcapsules and allantoin microcapsules, and then place them in a water bath at 60°C for 30 minutes;

[0044] (3) Mix and heat the water phase raw materials to 65°C-70°C, mix the oil phase raw materials and heat to 70°C-80°C to melt them uniformly, add the oil phase and the water phase to the emulsification tank separately, while adding (1 Items) and (2) were added to the emulsification tank, maintained at 70℃, homogenized for 10min-30min, cooled to about 40℃, added flavors and preservatives and stirred evenly to obtain the repair emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com