Process for optimizing production of germinated brown rice

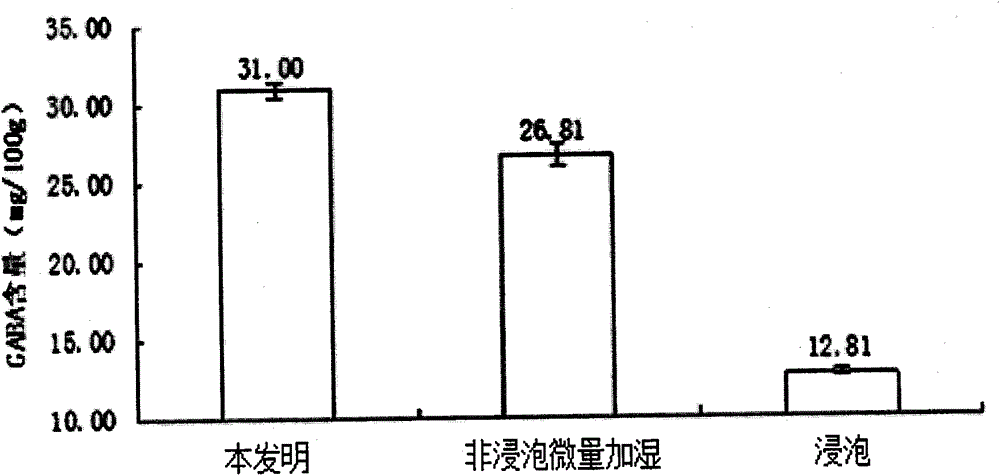

A technology of germinated brown rice and brown rice, which is applied in the field of grain deep processing, can solve problems that do not involve the water absorption characteristics of brown rice, and achieve the effect of low crack growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] (1) Pre-germination treatment of brown rice: remove impurities, broken grains, no germs, mildewed grains and heterochromatic grains of the raw brown rice, then sterilize it with ultraviolet light for 10-15 minutes, determine the moisture content of the raw material to be 12%, and weigh 10kg for use. .

[0017] (2) Brown rice moisture adjustment: Put the brown rice raw material processed in step (1) at room temperature. In this example, the weight of the brown rice raw material is 10 kg, the initial moisture content is 12%, and the initial moisture quality of the material is 1.2 kg. Through real-time monitoring of the flow rate of the water adding nozzle and the moisture content of the brown rice material, before the moisture content of the material is 18%, the hourly increase rate of the moisture content is selected to be an average of 1.0% / h, by the formula: water quality = (target moisture content × initial moisture content of the material Mass-initial material mass) / (1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com