Lactobacillus acidophilus pomace fermented feed and production process thereof

A Lactobacillus acidophilus and fermented feed technology, applied in the field of feed production, can solve the problems of vitamin nutrient loss, high investment and production costs, and difficult implementation of industrialized production, etc. effect of food intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

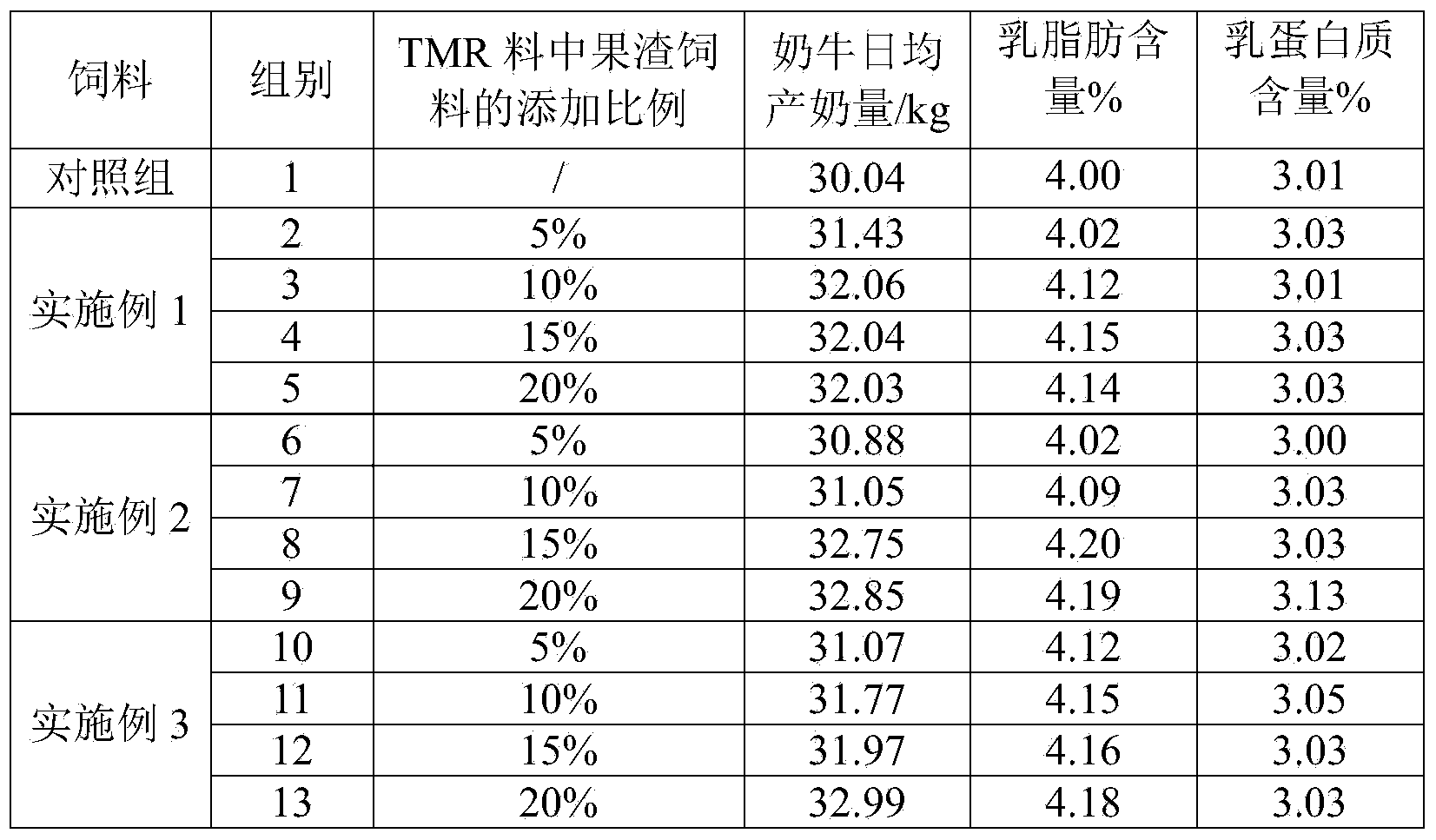

Examples

Embodiment 1

[0019] ① Strain propagation process: Lactobacillus acidophilus freeze-dried powder → A activation → B cultivation → C liquid cultivation → D inoculation expansion cultivation → E cultivation completion → F strain. Among them, the freeze-dried powder of Lactobacillus acidophilus was purchased from China Industrial Microorganism Culture Collection Management Center, and the preservation number is CICC6074.

[0020] A. activation

[0021] Wipe the seed tube with absorbent cotton dipped in 75% alcohol, then heat the top of the seed tube on a flame, and avoid direct heating of the bacteria or overheating. Drop sterile water onto the top of the heated inoculation tube to crack the glass, and knock off the top of the cracked inoculation tube with a file or tweezers. Use a sterile pipette to draw 0.3-0.4mL MRS liquid medium, drop it into the strain tube, and shake gently to dissolve the freeze-dried bacteria into a suspended liquid. Take about 0.2mL of bacterial suspension, transfer...

Embodiment 2

[0031] On the basis of Example 1, dry fermented pomace feed was prepared. The wet pomace fermented feed is fed through the scraper conveyor belt, and the impurities are removed again. The wet pomace fermented feed is transported into the mixer through the conveying auger, and the wet pomace fermented feed is evenly dispersed to avoid the state of agglomeration or block formation. The scattered wet pomace fermented feed enters the drying drum, and through the continuous rotation of the drum, the material is almost always in the air, reducing the contact time of the material with the drum wall, and avoiding agglomeration caused by sticking to the drum wall. After the dried pomace feed is decontaminated again, it enters the cooling bin, and is cooled by the action of the cooling fan. The cooled fruit pomace feed enters the silo to be powdered, and the pomace feed is crushed with a hammer mill according to the required particle size, with a particle size of 5.5mm; the produced du...

Embodiment 3

[0033] After Example 2, the pulverized pomace feed was granulated through the following process steps.

[0034] The crushed pomace feed enters the bin to be granulated, and then enters the modulator after being demagnetized by the permanent magnet cylinder, and the material is prepared before granulation with a steam pressure of 0.25-0.35Mpa. The compression ratio is used for granulation. The granulated pomace feed enters the cooling bin, and the granulated product is cooled by the action of the cooling fan. After cooling, the iron impurities are removed again, and then enter the vibrating grading screen for grading treatment. After processing, unqualified products are returned and processed again; products with qualified particle size enter the finished product warehouse, are weighed by electronic scales, and are packaged into products after entering the filling machine.

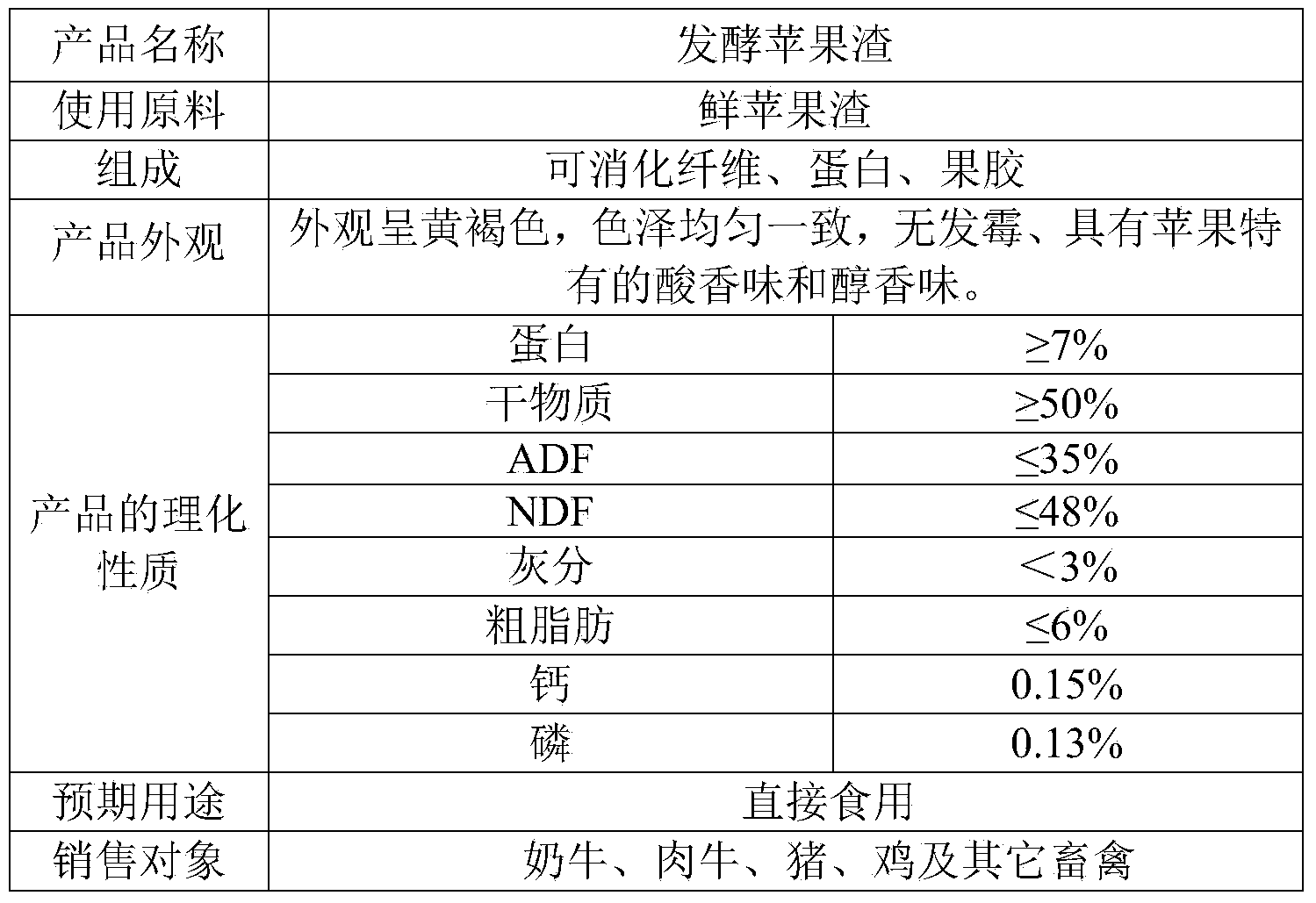

[0035] Table 1 Appearance and physicochemical properties of fermented pomace feed

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com